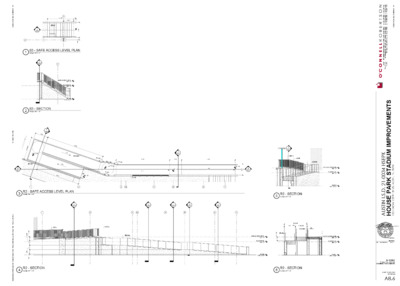

14.3 - 1301 Shoal Creek Blvd - House Park - Site Plan and Drawings (6) — original pdf

Backup