14.3 - 1301 Shoal Creek Blvd - House Park - Site Plan and Drawings (3) — original pdf

Backup

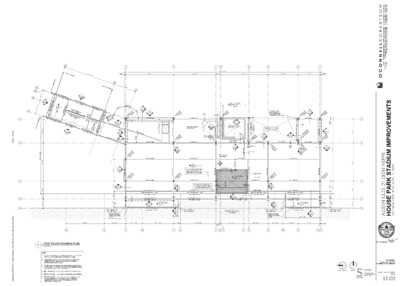

. 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A S1 1" (CL OF BEAM) 21' - 10" 1 EOD = 7" 2 3 3.2 4 5 6 7 20' - 1" 17' - 9 1/2" 19' - 11" 12' - 8" 9' - 1" EOD = 7" 82' - 8 1/2" 2' - 0" S2 1" (CL OF BEAM) 9' - 4 7/8" S3 R) E G RIN T F S L O " (C 1 SA SA.1 SB " 4 " 4' - 3 SC " 1 5' - 1 R) E G RIN T F S L O " (C 1 HSS12X6X3/8 (LSV) TOS = 500' -6 1/4" 2 S5.30 HSS12X6X3/8 (LSV) TOS = VARIES " 0 1/4 3/8 X 1 6 9' - X 6 9 S S = 4 S H O T HSS12X6X3/8 (LSV) TOS = VARIES HSS12X6X3/8 (LSV) TOS = VARIES 3 S6.02 V) S 6 1/4" 3/8 (L 0' - 0 S = 5 X 6 X 2 1 S S H O T C = O T 4 1/4" 0' - 0 5 HSS12X6X3/8 (LSV) TOS = 500' -6 1/4" 21' - 8" HSS12X6X3/8 (LSV) TOS = VARIES 1 S5.30 HSS12X6X3/8 (LSV) TOS = 505' -2" V) S 3/8 (L 2" 5' - 0 S = 5 X 6 X 2 1 S S H O T 3/8 6" 4' - X 6 0 X S = 5 6 S S H O T HSS6X6X3/8 (LSV) TOS = 504' -6" 3/8 6" C = 5'-0" 4' - X 6 O 5' - 1 0 X HSS12X6X3/8 (LSV) T S = 5 6 S S TOS = 505' -2" H O T 0 5 " 0 0 ° 0 1.0 7 ° 0 0 0 . 9 1 4 S6.02 6 HSS12X6X3/8 (LSV) S5.12 19.000° H S S 6 X 6 X 3/8 3/S 5.02 6 S5.12 7 1 . 0 0 0 ° 2 S6.01 W12X26 (20) 1 S6.01 HSS12X6X3/8 (LSV) 1 S5.13 W12X19 (10) ° 0 0 0 . 9 1 W12X19 (20) W12X19 (18) W14X22 (22) W12X19 (20) W12X19 (18) W12X19 (8) W12X19 (12) W12X19 (8) 2' - 6" 2' - 1 1/2" " 6 - ' 2 " 8 / 5 1 - ' 3 W12X19 (18) CMU WALL BELOW -SEE 6/S5.02 H S S 6 X 6 X 3/8 3/S 5.02 H S S 6 X 6 X 3/8 3/S 5.02 T Y P 3 S5.02 H S S 6 X 6 X 3/8 S T U B C O L T Y P 10 S5.01 ) 0 1 ( 9 1 X 2 1 W ) 8 2 ( 4 8 X 7 2 W BRICK RELIEF ANGLE ELEVATION = 505' - 0" SEE 6/S4.01 = D O E " 7 1' - 0" 7" H S S 6 X 6 X 3/8 3/S 5.02 " 4 / 3 9 " 4 / 1 1 - ' 6 EOD = 7 1/2" 4 S5.02 ) 0 1 ( 9 1 X 2 1 W ) 0 1 ( 9 1 X 2 1 W H S S 3 / S 6 X " 6 5 . 0 2 6 X 3 / 8 W10X15 (2) 6 S5.10 " 4 / 1 3 - ' 4 " 3 LW Concrete on Metal Deck W12X19 (12) " 4 " 6 8 S5.10 ) 8 2 ( 4 8 X 7 2 W H S S 6 X 6 X 3/8 S T U B C O L W12X19 (18) TOC = 505' - 0" 6" THICK (TOTAL) NW CONC SLAB ON 3VLI STEEL DECK - SEE STRUCTURAL NOTES 6" THICK (TOTAL) NW CONC SLAB ON 1.3CV STEEL DECK - SEE STRUCTURAL NOTES 4 5/8" W12X19 (17) HSS12X6X3/8 (LSV) - LOW TOS =500' - 10 1/2" HSS12X6X3/8 (LSV) TOS =500' - 10 1/2" W12X19 (19) HIGH HSS12X6X3/8 (LSV) - LOW TOS =500' - 10 1/2" HSS12X6X3/8 (LSV) TOS =500' - 10 1/2" 3 S6.01 TO GRATING = 501' - 0" HSS12X6X3/8 (LSV) TOS = 500' - 10 1/2" SEE 3/S5.31 FOR ATTACHMENT OF DELEGATED STAIR LANDING TO STRUCTURE H S S 6 X 6 X 3/8 3/S 5.02 6 S5.12 W12X19 (8) H S S 6 X 6 X 3/8 3/S 5.02 SIM 4 S5.02 ELEVATOR SHAFT W12X19 (10) W12X19 (12) " 5 - ' 1 = D O E " 2 / 1 5 ) 2 ( 9 1 X 2 1 W ) 6 ( 9 1 X 2 1 W E L G N A F E I L E R K C R B I " 0 - ' 5 0 5 = . V E L E 1 0 . 4 S / 6 E E S H S S 6 X 6 X 3/8 3/S 5.02 ) 3 E T O N E E S = S O T ( 9 1 X 2 1 W EOD = 6" 1' - 11 1/4" DELEGATED DESIGN STAIR BY OTHERS 8 S5.12 H S S 6 X 6 X 3 / S 3 / 8 5 . 0 2 ) 8 ( 9 1 X 2 1 W EOD = 7" H S S 6 X 6 X 1/4 S T U B C O L A B O V E H S S 6 X 6 X 3 / S 3 / 8 3 5 . 0 2 T Y P S5.02 8 S5.12 = D O E " 8 / 1 7 CONC. CURB 8' - 6 1/4" W12X19 (18) ** TOC AT DRAIN = 504' - 11" 3" 6" 4" VARIES ) 4 ( 9 1 X 2 1 W ) 4 ( 9 1 X 2 1 W ) 8 2 ( 4 8 X 7 2 W H S S 6 X 6 X 3/8 S T U B C O L T Y P 10 S5.01 W12X19 (18) HSS12X6X3/8 (LSV) - LOW TOS =500' - 10 1/2" 2 S5.13 HSS12X6X3/8 (LSV) TOS =500' - 10 1/2" " 3 - ' 2 W12X19 (22) HSS12X6X3/8 (LSV) - LOW TOS =500' - 10 1/2" HSS12X6X3/8 (LSV) TOS =500' - 10 1/2" HSS12X6X3/8 (LSV) TOS = 500'-10 1/2" 5 S5.11 1' - 9 7/8" EXISTING STRUCTURE TO REMAIN SIM 5 S5.11 HSS12X6X3/8 (LSV) TOS = 500'-10 1/2" METAL GRATING -SEE STRUCTURAL NOTES TO GRATING = 501' - 0" EOD = 7" HSS12X6X3/8 (LSV) TOS = 500' - 10 1/2" 5 S5.11 14' - 5 3/8" W12X19 (20) W12X19 (18) W14X22 (22) = D O E " 7 ) 8 ( 9 1 X 2 1 W 1 S6.02 H S S 6 X 6 X 3/8 3/S 5.02 7 S5.12 " 7 - ' 6 2 ) 8 2 ( 8 6 X 4 2 W H S S 6 X 6 X 3/8 S T U B C O L " 3 - ' 4 " 3 - ' 5 = D O E " 0 - ' 1 " 4 / 1 5 - ' 3 ) V F ( HSS12X6X3/8 (LSV) TOS = 500'-10 1/2" A B C D XA " 0 - ' 0 1 " 0 - ' 6 1 " 6 - ' 7 " 1 1 - ' 3 ) 0 1 ( 9 1 X 2 1 W * * ) 8 2 ( 6 7 X 4 2 W H S S 6 X 6 X 3/8 S T U B C O L H S S 6 X 6 X 3/8 S T U B C O L 2 S6.02 6 S5.12 " 2 - ' 9 " 3 - ' 4 = D O E " 0 - ' 1 " 4 / 1 5 - ' 3 ) V F ( HSS12X6X3/8 (LSV) TOS = 500'-10 1/2" METAL GRATING -SEE STRUCTURAL NOTES 16' - 0" 9' - 0 3/8" 6' - 11 5/8" 13' - 1 3/8" 2' - 10 5/8" 14' - 10 7/8" 9' - 7 7/8" 10' - 3 1/8" 6' - 2 7/8" 6' - 5 1/8" 9' - 1" 5 7/8" 1' - 7 1/8" 4 7/8" X4 X5 1 X6 2 X7 3 X8 3.2 X9 4 5 X10 6 7 X11 " 0 - ' 0 1 " 6 5 2 / 1 0 1 - ' 1 3 " 0 - ' 6 1 " 6 - ' 7 " 3 - ' 2 " 1 1 - ' 3 A B C D XA M A 9 2 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A 1 FIRST FLOOR FRAMING PLAN 1/4" = 1'-0" NOTES: 1. ALL EXTERIOR CONCRETE FLOORS TO BE PROTECTED WITH A TRAFFIC COATING. REF ARCH FOR ADDITIONAL INFO. 2. COMPOSITE BEAMS INDICATED AS W12X19 (X)** REQUIRE 4" HEADED STUDS IN LIEU OF TYPICAL LENGTH STUDS IN LOCATIONS WITH SLAB DROPS. 3. TOS ELEVATION TO BE COORDINATED WITH DELEGATED STAIR DESIGN. BEAM IS DROPPED TO ALLOW STAIR LANDING FRAMING OVER AND ATTACH TO THE TOP FLANGE. 4. INDICATES MOMENT CONNECTION. SEE TYPICAL DETAILS. 5. INDICATES BRACE FRAME. SEE S6 SERIES. 6. INDICATES EXTENT OF VENTED FLOOR SYSTEM. VENTED FLOOR SYSTEMS SHALL UTILIZE NON- COMPOSITE 1.3CV DECK. SEE STRUCTURAL NOTES FOR ADDITIONAL INFORMATION. NO. DESCRIPTION Revisions: DATE N N TRUE NORTH PLAN NORTH 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES FIRST FLOOR FRAMING PLAN S1.03 05/10/2024 . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A 2 3 3.2 4 5 6 7 20' - 1" 17' - 9 1/2" 19' - 11" 82' - 8 1/2" 2' - 0" 12' - 8" 7" 9' - 1" EOD = 7" W12X19 (20) W12X19 (18) W12X19 (8) W12X19 (12) = D O E " 7 W12X19 (18) EOD = 7 1/2" 4 S5.02 ) 0 1 ( 9 1 X 2 1 W BRICK RELIEF ANGLE ELEVATION = 518' - 0" SEE 6/S4.01 ELEVATOR SHAFT W12X19 (10) W12X19 (12) " 5 - ' 1 6 S5.10 = D O E " 2 / 1 5 ) 2 ( 9 1 X 2 1 W ) 6 ( 9 1 X 2 1 W W12X19 (18) TOC = 518' - 0" 6" THICK (TOTAL) NW CONC SLAB ON 3VLI STEEL DECK - SEE STRUCTURAL NOTES ) 4 2 ( 4 4 X 1 2 W ) 0 1 ( 9 1 X 2 1 W ) 4 2 ( 4 4 X 1 2 W T Y P 11 S5.01 DELEGATED DESIGN STAIR BY OTHERS SIM 4 S5.02 4 S5.12 E L G N A F E I L E R K C R B I " 0 - ' 8 1 5 = . V E L E 1 0 . 4 S / 6 E E S ) 3 E T O N E E S = S O T ( 9 1 X 2 1 W EOD = 6" 1' - 11 1/4" S I M 2 S5.12 W12X19 (8) TOS = 517' - 4" W12X19 (8) TOS = 517' - 4" ) 8 ( 9 1 X 2 1 W " 4 - ' 7 1 5 = S O T W12X19 (8) " 6 " 4 9 S5.10 EOD = 7" ) 8 ( 9 1 X 2 1 W " 4 - ' 7 1 5 = S O T 4 S5.12 = D O E " 8 / 1 7 ) 4 2 ( 4 4 X 1 2 W T Y P 11 S5.01 " 0 - ' 1 " 6 - ' 1 = D O E " 0 - ' 1 1 S5.12 3 S5.12 = D O E " 7 TOC AT DRAIN = 517' - 10" 2 S5.12 SIM ) 8 ( 9 1 X 2 1 W " 4 - ' 7 1 5 = S O T 1 S6.02 6" THICK (TOTAL) NW CONC SLAB ON 1.3CV STEEL DECK - SEE STRUCTURAL NOTES CONCRETE CURB 3 S5.12 ) 3 2 ( 5 3 X 8 1 W A B C " 0 - ' 0 1 " 0 - ' 6 1 " 8 - ' 4 = D O E " 6 W12X19 (20) W12X19 (18) W12X19 (18) W14X22 (22) W12X19 (20) W12X19 (18) W12X19 (18) W12X19 (22) W12X19 (20) W12X19 (18) W14X22 (22) 20' - 1" 17' - 9 1/2" 2' - 0" 19' - 11" 12' - 8" 9' - 1" 1 2 3 3.2 4 5 6 7 S1 1" (CL OF BEAM) 21' - 10" R) E G RIN T F S L O " (C 1 3 S6.02 V) S 4 5/8" 3/8 (L 1' - 0' - 4 1 S = 5 1 " X 6 X 2 1 S S H O T SC HSS12X6X3/8 (LSV) TOS = 511' -4 5/8" C = O T 2 5/8" 1' - 1 5 3/8 X 6 X 6 S S H 8 5/8" 0' - 1 S = 5 O T 2 S5.30 HSS12X6X3/8 (LSV) TOS = VARIES HSS12X6X3/8 (LSV) TOS = VARIES HSS12X6X3/8 (LSV) TOS = VARIES HSS12X6X3/8 (LSV) TOS = 511' -4 5/8" SA SA.1 SB " 4 " 4' - 3 " 1 5' - 1 R) E G RIN T F S L O " (C 1 " 7 = D O E " 0 - ' 0 1 HSS12X6X3/8 (LSV) TOS = VARIES 1 S5.30 C = O T 3/8 6" 7' - X 6 1 X S = 5 6 S S H HSS12X6X3/8 (LSV) TOS = 518' -2" " 0 8' - 1 5 O T 3/8 6" 7' - X 6 1 X S = 5 6 S S H O T " 0 5' - 1 19.000° 0 ° 0 1.0 7 2 S5.12 7 1 . 0 0 0 ° 2 S6.01 W12X26 (20) 3/8 X 6 X 2 1 S S H 2" 8' - 1 S = 5 O T 4 S6.02 ° 0 0 0 . 9 1 S I M 3 S5.12 HSS12X6X3/8 (LSV) 1 HSS12X6X3/8 (LSV) S5.13 ) 0 1 ( 9 1 X 2 1 W W12X19 (10) 1 EOD = 7" S2 9' - 4 7/8" S3 2 S6.02 ) 3 2 ( 5 3 X 8 1 W 3 S5.12 " 3 - ' 3 3 " 0 - ' 6 1 " 8 - ' 5 " 8 - ' 6 = D O E " 0 - ' 1 A B C M A 9 2 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A 1 SECOND FLOOR FRAMING PLAN 1/4" = 1'-0" NOTES: 1. ALL EXTERIOR CONCRETE FLOORS TO BE PROTECTED WITH A TRAFFIC COATING. REF ARCH FOR ADDITIONAL INFO. 2. COMPOSITE BEAMS INDICATED AS W12X19 (X)** REQUIRE 4" HEADED STUDS IN LIEU OF TYPICAL LENGTH STUDS IN LOCATIONS WITH SLAB DROPS. 3. TOS ELEVATION TO BE COORDINATED WITH DELEGATED STAIR DESIGN. BEAM IS DROPPED TO ALLOW STAIR LANDING FRAMING OVER AND ATTACH TO THE TOP FLANGE. 4. INDICATES MOMENT CONNECTION. SEE TYPICAL DETAILS. 5. INDICATES BRACE FRAME. SEE S6 SERIES. 6. INDICATES EXTENT OF VENTED FLOOR SYSTEM. VENTED FLOOR SYSTEMS SHALL UTILIZE NON- COMPOSITE 1.3CV DECK. SEE STRUCTURAL NOTES FOR ADDITIONAL INFORMATION. NO. DESCRIPTION Revisions: DATE N N TRUE NORTH PLAN NORTH 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES SECOND FLOOR FRAMING PLAN S1.04 05/10/2024 . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A S1 1 2 3 3.2 4 5 6 7 20' - 1" 17' - 9 1/2" 2' - 0" 11' - 10" 8' - 1" 12' - 8" 9' - 1" 2' - 11 1/2" 2' - 5 1/2" 85' - 1" EOD = 7 1/2" EOD = 1' - 3 1/4" 21' - 10" EOD = 7" S2 9' - 4 7/8" S3 SA SA.1 SB " 4 " 4' - 3 BOD = 527' -9 1/2" 2 S5.30 W12X19 " 1 5' - 1 SC 9 1 X 2 1 W 5 1 X 0 1 W 1.5B22 ROOF DECK - SEE STRUCTURAL NOTES 3 S6.02 " 7 = D O E " 0 - ' 0 1 " 2 / 1 1 - ' 4 3 " 0 - ' 6 1 " 2 / 1 0 - ' 7 19.000° 0 ° 0 1.0 7 4 S5.23 7 1 . 0 0 0 ° 2 S6.01 W12X22 1 K 2 1 5 1 X 0 1 W W12X19 1 S5.30 BOD = 528' -0 5/8" 5 1 X 0 1 W W10X15 5 1 X 0 1 W ° 0 0 0 . 9 1 4 S6.02 5 1 X 0 1 W 5 1 X 0 1 W 2 S5.23 W12X19 5 1 X 0 1 W 5 1 X 0 1 W 3 S5.23 W12X19 BOD = 530' - 6 1/2" BOD = 530' - 6 1/2" 2 S5.24 7 S5.23 W12X19 W14X22 W12X19 12K1 @ 6' - 0" O.C. - MAX. 12K1 @ 6' - 0" O.C. - MAX. W8X15 HOIST BEAM ELEVATOR SHAFT 9 1 X 2 1 W 1 K 2 1 1 K 2 1 " 0 - ' 4 1 K 5 . 2 12K1 @ 6' - 0" O.C. - MAX. JOIST HEADER W12X19 W12X19 W14X22 1 K 5 . 2 W12X19 W12X19 1 K 5 . 2 1 K 2 1 1 S5.24 9 1 X 2 1 W " 2 / 1 5 " 5 - ' 1 W12X19 ROOF HATCH 1.5B22 ROOF DECK - SEE STRUCTURAL NOTES 12K1 @ 6' - 0" O.C. - MAX. 12K1 @ 6' - 0" O.C. - MAX. 12K1 @ 6' - 0" O.C. - MAX. 12K1 @ 6' - 0" O.C. - MAX. W O L 8 / 3 X 6 X 2 1 S S H " 2 / 1 1 - ' 7 2 5 = . . S O B . I H G H 2 2 X 4 1 W 2.5K1 2 S6.02 6 2 X 6 1 W 2 S5.23 W12X19 W12X19 12K1 @ 6' - 0" O.C. - MAX. 12K1 @ 6' - 0" O.C. - MAX. 6 2 X 6 1 W T Y P 1 S5.02 6 2 X 6 1 W BOD = 531' - 1" W12X19 12K1 @ 6' - 0" O.C. - MAX. 6 2 X 6 1 W T Y P 1 S5.02 9 1 X 2 1 W W12X19 9 1 X 2 1 W 9 1 X 2 1 W W14X22 W14X22 W14X22 W14X22 1 S5.23 6 S5.23 9 1 X 2 1 W 1 S6.02 9 1 X 2 1 W 5 S5.23 6 2 X 6 1 W 2 2 X 4 1 W " 2 / 1 = D O E " 0 - ' 0 1 " 7 - ' 3 3 " 0 - ' 6 1 A B C " 2 / 1 0 - ' 7 " 2 / 1 6 - ' 7 = D O E EOD = 7" 20' - 1" 17' - 9 1/2" 2' - 0" 19' - 11" 12' - 8" 9' - 1" EOD = 2' - 11 1/2" 85' - 1" 1 2 3 3.2 4 5 6 7 1 ROOF FRAMING PLAN 1/4" = 1'-0" NOTES: 1. INDICATES APPROXIMATE LOCATION OF ROOF DAVIT SYSTEM. REFER TO ARCHITECTURAL DRAWINGS FOR EXACT LOCATIONS. SEE 7/S5.21 FOR STRUCTURAL ATTACHMENT DETAIL. 2. INDICATES MOMENT CONNECTION. SEE TYPICAL DETAILS. 3. INDICATES BRACE FRAME. SEE S6 SERIES. NO. DESCRIPTION Revisions: DATE N N TRUE NORTH PLAN NORTH 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES ROOF FRAMING PLAN S1.05 A B C M A 0 3 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A 05/10/2024 X16 EXISTING GRANDSTAND TO REMAIN DN DOWN L I V C I . F E R = . . C O T . DOWN DN DN DOWN L I V C I . F E R = . . C O T . UP 4 S1.10 3 S1.10 L I V C I . F E R = . . C O T . 3 S1.10 1 CONCRETE RAMP PLAN - EAST GRANDSTAND 1/4" = 1'-0" 3 SECTION AT CONCRETE RAMP 3/4" = 1'-0" #4 DOWELS @ 12" O.C. -PROVIDE STD HOOK AT BOTTOM OF FOOTING 1' - 6" 1' - 6" REINF. FOOTING W/ #4 @ 12" O.C. EACH WAY 5" SLAB ON COMPACTED FILL -REINF. W/ #3 @ 12" O.C. EACH WAY T.O.C. = REF CIVIL T.0. WALL = " 8 . X A M " 6 . I N M " 0 1 " 6 - ' 3 FINISH GRADE (BW) REF. CIVIL T.O. FOOTING = 6" 6" 2'-0" " 0 - ' 2 #4 X DOWELS @ 12" O.C. #4 @ 12" O.C. EACH WAY LOWER SLAB (NOT PRESENT AT SIM) -REINF. W/ #3 @ 12" O.C. EACH WAY -DOWEL 4" INTO CONCRETE STEM WALL W/ HILTI HIT-HY 200 EPOXY X16 = . C O T . L I V DN C I . F E R D N A T S D N A R G G N T S X E I I I N A M E R O T SLOPE DOWN SLOPE DOWN T.OC. = REF. CIVIL 4 S1.10 L I V C I . F E R = . C O T . SIM. 3 S1.10 2 CONCRETE RAMP PLAN - WEST GRANDSTAND 1/4" = 1'-0" 4 SECTION AT CONCRETE STAIRS 3/4" = 1'-0" #4 NOSING BAR, TYP. T.O.C. = REF. CIVIL #4 DOWELS @ 12" O.C. -PROVIDE STD HOOK AT BOTTOM OF FOOTING FINISH GRADE = REF. CIVIL T.O. FOOTING = . I N M " 0 - ' 1 REINF. FOOTING W/ #4 @ 12" O.C. EACH WAY REINF. W/ #3 @ 12" O.C. EACH WAY NO. DESCRIPTION Revisions: DATE 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES CONCRETE RAMP PLANS AND DETAILS S1.10 X19 X20 XE M A 1 3 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A 05/10/2024 X1 X2 X3 X4 X6 X7 X8 X9 X10 X11 X12 X13 X14 X15 X16 2 4 6 c o u n ts 2 2 2 4 4 4 5 counts 4 5 counts 2 2 2 2 1 2 c o u 4 n ts 2 4 counts SA.1 2 5 counts 4 2 2 2 2 2 counts 4 2 counts 2 2 1 4 4 counts 4 2 1 2 2 2 counts 1 4 5 c 4 4 counts o u n ts 2 3 c o u n ts 2 2 2 4 counts 4 14 counts 2 5 2 2 2 2 counts 4 10 counts 4 counts 2 4 c o u 3 n ts 4 6 counts 2 2 4 2 1 2 2 counts 2 2 2 5 counts 6 counts 4 4 4 10 counts 5 2 4 2 2 counts 2 2 9 counts 4 c o u 4 n ts 2 5 2 1 5 4 c o u 4 n ts 4 3 1 4 c o u 2 n t s 4 6 2 6 4 1 2 4 counts 2 5 counts 2 2 4 counts 2 5 2 2 2 3 2 2 counts 2 4 10 counts 12 counts 2 2 2 4 counts 2 2 2 4 2 counts 8 1 1 c o u 2 n t s 3 2 2 2 counts 2 2 2 4 9 counts 4 5 counts 2 11 counts 2 4 2 2 2 2 2 4 10 counts 2 4 2 2 counts 1 6 3 2 2 2 1 3 XA 6 3 2 2 2 counts 2 4 1 2 counts 3 6 5 1 3 counts 4 5 counts 4 2 2 2 5 3 2 2 c o u n ts 2 2 3 1 2 2 3 2 3 4 2 2 2 2 2 6 counts 2 2 1 2 2 7 c o 2 u 2 n ts 1 EAST GRANDSTAND REPAIR PLANS - BELOW STANDS 1/8" = 1'-0" PLAN TAG REPAIR SCHEDULES PLAN TAG 1. 2. 3. 4. 5. 6. 7. REPAIR DETAIL 1/S2.12 2/S2.12 3/S2.12 4/S2.12 5/S2.12 6/S2.12 7/S2.12 S3 X5 1 S3 X5 X18 X19 X20 N X18 X19 X20 M A 4 3 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A X1 X2 X3 X4 X6 X7 X8 X9 X10 X11 X12 X13 X14 X15 X16 POWER WASH AND PAINT ALL SIDES OF PERIMETER WALLS -REF. ARCH. FOR PAINT SPECIFICATION D XA 4 5 1 2 4 2 counts 4 REPAIR CONCRETE AFTER PRESS BOX DEMOLITION AS NEEDED PER DETAIL X/SX.XX 4 SA.1 4 4 4 4 4 4 4 4 4 4 4 4 4 counts 4 4 4 UP 1 4 4 4 12 counts 4 4 6 4 DN 4 4 4 4 4 4 4 4 4 3 7-A UP DOWN 4 4 4 4 4 3 counts 4 2 counts 4 4 counts 4 3 counts 4 4 4 4 4 4 4 2 counts 4 2 counts 4 4 4 4 1 1 10 counts 1 DN POWER WASH AND PAINT ALL SIDES OF PERIMETER WALLS -REF. ARCH. FOR PAINT SPECIFICATION 4 4 4 4 1 4 POWER WASH AND PAINT ALL SIDES OF PERIMETER WALLS -REF. ARCH. FOR PAINT SPECIFICATION 2 EAST GRANDSTANDS REPAIR PLANS - ABOVE STANDS 1/8" = 1'-0" N AT RAMPS AND ADA PLATFORMS (HATCHED AREA): 1) THERE ARE 35 VERTICAL PIPE RAILS THAT NEED CONCRETE REPAIR AT BASE AND PIPE REPAIR OR REPLACEMENT PER 7/S2.12. 2) APPROX. 46 L.F. OF NON-STRUCTURAL SURFACE CRACKS SHALL BE REPAIRED PER 2/S2.12 PLAN TAG REPAIR SCHEDULES PLAN TAG 1. 2. 3. 4. 5. 6. 7. REPAIR DETAIL 1/S2.12 2/S2.12 3/S2.12 4/S2.12 5/S2.12 6/S2.12 7/S2.12 . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A NO. DESCRIPTION Revisions: DATE 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES EAST GRANDSTAND REPAIR PLANS S2.00 05/10/2024 X1 X2 X3 X4 X5 X6 X7 X8 X9 X10 X11 X12 X13 X14 X15 X16 2 2 14 counts 3 counts 4 counts 6 2 4 5 counts 2 5 6 6 4 5 4 2 2 2 4 c o u 4 n ts 2 2 2 2 6 2 2 4 counts 2 2 2 5 counts 2 6 counts 2 2 2 2 2 2 2 2 3 counts 2 3 counts 3 counts 2 2 3 counts 2 3 counts 2 2 2 2 2 4 3 counts 2 2 2 2 4 2 2 2 4 6 4 3 counts 2 2 4 2 4 4 2 counts 2 counts 4 4 2 2 counts 2 counts 2 2 2 2 counts 2 4 3 counts 4 3 counts 2 6 counts 2 2 6 counts 2 2 4 10 counts 4 10 counts 2 2 2 11 counts 2 2 2 10 counts 2 2 2 counts 2 2 counts 2 2 2 2 2 4 counts 2 2 2 2 2 2 2 2 2 2 2 3 counts 2 2 2 4 counts 2 2 2 4 2 2 4 2 2 2 4 2 counts 2 2 counts 4 3 counts 6 2 3 counts 5 counts 4 5 counts 2 6 4 2 2 4 2 2 2 6 counts 7 counts 4 4 6 c o u n ts 4 5 c o u n ts 4 6 counts 2 2 4 7 counts 2 6 2 2 4 5 counts 4 12 counts 10 counts 4 8 c o u n ts 4 4 12 counts 6 4 5 counts 2 2 6 6 6 2 2 3 counts 4 8 counts 6 counts 4 6 c o u 2 n ts 2 2 4 c o u 4 n t s 8 c o u n 4 ts 3 0 c o u 4 n t s 2 4 5 c o u 2 n ts 4 c o u 2 n ts 2 2 2 6 counts 2 2 4 2 2 2 4 8 counts 2 2 5 5 2 2 2 2 4 60 counts 4 18 counts 4 9 counts 4 6 counts 4 8 counts 4 3 c o u n ts 4 6 counts 3 2 2 2 4 6 counts 1 WEST GRANDSTAND REPAIR PLANS - BELOW STANDS 1/8" = 1'-0" PLAN TAG REPAIR SCHEDULES PLAN TAG 1. 2. 3. 4. 5. 6. 7. REPAIR DETAIL 1/S2.12 2/S2.12 3/S2.12 4/S2.12 5/S2.12 6/S2.12 7/S2.12 X1 X2 X3 X4 X5 X6 X7 X8 X9 X10 X11 X12 X13 X14 X15 X16 7 7 7 7 XE DN 7 1 4 1 6 5 4 4 7 4 4 DN DOWN UP 4 UP 4 4 4 4 4 4 4 4 4 4 AT RAMPS AND ADA PLATFORMS (HATCHED AREA): 1) THERE ARE 35 VERTICAL PIPE RAILS THAT NEED CONCRETE REPAIR AT BASE AND PIPE REPAIR OR REPLACEMENT PER 7/S2.12. 2) APPROX. 60 L.F. OF NON-STRUCTURAL SURFACE CRACKS SHALL BE REPAIRED PER 2/S2.12 4 4 4 DN 6 7 4 4 4 6 4 6 6 4 4 4 REPAIR CONCRETE AFTER PRESS BOX DEMOLITION AS NEEDED PER DETAIL X/SX.XX 4 4 5 C O U N T S 4 4 4 4 8 C O U N T S 4 4 4 4 4 4 6 POWER WASH AND PAINT ALL SIDES OF PERIMETER WALLS -REF. ARCH. FOR PAINT SPECIFICATION 6 4 4 4 4 4 4 6 6 6 6 6 POWER WASH AND PAINT ALL SIDES OF PERIMETER WALLS -REF. ARCH. FOR PAINT SPECIFICATION 6 6 6 6 6 2 WEST GRANDSTANDS REPAIR PLANS - ABOVE STANDS 1/8" = 1'-0" PLAN TAG REPAIR SCHEDULES PLAN TAG 1. 2. 3. 4. 5. 6. 7. REPAIR DETAIL 1/S2.12 2/S2.12 3/S2.12 4/S2.12 5/S2.12 6/S2.12 7/S2.12 2 7 4 2 4 4 . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A NO. DESCRIPTION Revisions: DATE 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES WEST GRANDSTAND REPAIR PLANS S2.01 XE XF XG XH N XF XG XH N POWER WASH AND PAINT ALL SIDES OF PERIMETER WALLS -REF. ARCH. FOR PAINT SPECIFICATION M A 8 3 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A 05/10/2024 CONCRETE PATCH REPAIR PROCEDURE: AFTER EACH REPAIR AREA HAS BEEN PREPARED PER THE STRUCTURAL NOTES SECTION “CONCRETE MAINTENANCE - GENERAL NOTES”, FOLLOW THESE STEPS TO DETERMINE THE APPROPRIATE PATCH REPAIR PROCEDURE AND DETAILS: STEP 1 – EVALUATE REBAR EXPOSURE • REFER TO DETAIL 1/S2.10 TO DETERMINE THE PERCENTAGE OF REBAR EXPOSURE FOR EACH OCCURRENCE. ALSO DETERMINE THE PERCENTAGE OF LOST STEEL FOR EACH REINFORCING BAR. STEP 2 – DETERMINE IF CHIPPING BEHIND BAR IS NECESSARY IF SURFACE RUST IS PRESENT, THEN CHIPPING BEHIND BAR IS REQUIRED. FOR CLEAN BAR WITH NO RUST, CHIPPING WILL ONLY BE REQUIRED AS FOLLOWS: IF LESS THAN 50% OF THE REBAR IS EXPOSED AFTER REMOVAL OF UNSOUND CONCRETE, UNDERCUTTING/CHIPPING CONCRETE BEHIND THE BAR IS NOT REQUIRED AND A REPAIR PATCH MAY BE APPLIED. IF MORE THAN 50% OF THE REBAR IS EXPOSED AT ANY LOCATION ALONG THE LENGTH OF EXPOSED BAR, PROCEED WITH UNDERCUTTING/CHIPPING CONCRETE BEHIND THE REBAR PRIOR TO PATCHING PER DETAIL 2/S2.10. • • STEP 3 – SLAB EVALUATION OF REBAR SECTION LOSS • AT SLAB PATCH REPAIR LOCATIONS WHERE CONSECUTIVE REINFORCING BARS HAVE LOST LESS THAN 10% OF THE BAR AREA DUE TO CORROSION (I.E. BAR IS CLEAN OR ONLY SURFACE RUST IS PRESENT), ADDITIONAL REINFORCEMENT IS NOT REQUIRED AND PATCH MATERIAL MAY BE APPLIED PER THE APPLICABLE DETAILS. • AT SLAB PATCH REPAIR LOCATIONS WHERE ONE REINFORCING BAR HAS LOST MORE THAN 10% OF THE BAR AREA AND ADJACENT BARS ARE INTACT, ADDITIONAL REINFORCING IS NOT REQUIRED AND THE REPAIR PATCH MAY BE APPLIED. • AT SLAB PATCH REPAIR LOCATIONS WHERE CONSECUTIVE REINFORCING BARS HAVE LOST MORE THAN 10% OF THE BAR AREA DUE TO CORROSION (I.E. DEEP SURFACE RUST, SCALING, PITTING, OR DELAMINATION), CONSULT WITH EOR TO DETERMINE IF ADDITIONAL REINFORCEMENT IS REQUIRED BASED ON ANALYSIS AND LOCATION OF REPAIR. REFER TO DETAIL 5/S2.10 FOR TYPICAL REINFORCEMENT REQUIREMENTS, IF DETERMINED NECESSARY BY E.O.R. STEP 4 - GIRDER AND BEAM EVALUATION OF REBAR SECTION LOSS • WHERE REINFORCING BARS HAVE LOST LESS THAN 10% OF THE BAR AREA DUE TO CORROSION (I.E. BAR IS CLEAN OR ONLY SURFACE RUST IS PRESENT), ADDITIONAL REINFORCING IS NOT REQUIRED AND THE REPAIR PATCH MAY BE APPLIED. • AT GIRDER, BEAM, AND JOIST REPAIR LOCATIONS WHERE CONSECUTIVE REINFORCING BARS HAVE LOST MORE THAN 10% OF THE BAR AREAS (I.E. DEEP SURFACE RUST, SCALING, PITTING, OR DELAMINATION), PROVIDE ADDITIONAL BUNDLED REINFORCEMENT PER DETAIL 5/S2.10. STEP 5 - CONCRETE PATCHING • REFER TO “CONCRETE PATCHING MORTAR” STRUCTURAL NOTES FOR PRODUCT, SURFACE PREPARATION, AND INSTALLATION INFORMATION. THE CONCRETE CONTRACTOR PERFORMING THE WORK SHALL PROVIDE THE MOST APPROPRIATE PATCH MATERIALS FOR EACH REPAIR CONDITION AND SHALL DETERMINE THE PREFERRED METHOD OF APPLICATION (HAND-APPLIED, FORM AND PUMP, OR FORM AND POUR) TO PROVIDE THE BEST RESULT. • WHERE CONCRETE IS UNSOUND FOR FULL DEPTH OF STRUCTURAL MEMBER, REMOVE CONCRETE WITHIN COMPROMISED AREA WITHOUT CUTTING REINFORCEMENT AND APPLY PATCH PER DETAIL 3/S2.10. FOR AREAS THAT REQUIRE FULL-DEPTH REMOVAL OF MORE THAN 2’-0” IN ANY DIRECTION, CONTACT E.O.R. FOR FURTHER DIRECTION AND EVALUATION PRIOR TO PATCHING. • WHERE CONCRETE PATCH IS NOT FULL DEPTH OF THE STRUCTURAL MEMBER, APPLY PATCH PER DETAIL 3/S2.10 OR 4/S2.10 AS APPLICABLE. NOTES: 1. THESE DETAILS INCLUDES GRAPHICAL REPRESENTATIONS OF VARIOUS PERCENTAGES OF BAR EXPOSURE. EXISTING REINFORCEMENT EXISTING CONCRETE EXISTING REINFORCEMENT EXISTING CONCRETE 30% 40% EXAMPLE: EXPOSED PORTION OF BAR IS APPROXIMATELY 30% OF BAR CIRCUMFERENCE EXPOSED PORTION OF BAR IS APPROXIMATELY 40% OF BAR CIRCUMFERENCE ~30% EXPOSURE ~40% EXPOSURE EXISTING REINFORCEMENT EXISTING CONCRETE EXISTING REINFORCEMENT EXISTING CONCRETE 50% 60% EXPOSED PORTION OF BAR IS APPROXIMATELY 50% OF BAR CIRCUMFERENCE EXPOSED PORTION OF BAR IS APPROXIMATELY 60% OF BAR CIRCUMFERENCE ~50% EXPOSURE ~60% EXPOSURE NOTES: 1. WHERE POSSIBLE, USE OIL-FREE ABRASIVE BLASTING OR HIGH-PRESSURE WATER BLASTING TO REMOVE IMPURITIES AND UNSOUND CONCRETE. WHERE CONSTRUCTION METHODS ARE LIMITED, MECHANICAL METHODS SUCH AS WIRE BRUSHING, SANDING, CHIPPING, AND GRINDING ARE ACCEPTABLE ALTERNATIVES UNLESS NOTED OTHERWISE. 2. REPAIR CONFIGURATIONS SHOULD BE KEPT AS SIMPLE AS POSSIBLE, PREFERABLY WITH 90-DEGREE ANGLES AT PATCH AREA EDGES. FEATHERED EDGES ARE NOT ALLOWED. 3. SAWCUT OR SMOOTH CONCRETE EDGES SHOULD ALSO BE BLASTED OR ROUGHENED PRIOR TO PATCHING. 4. REFER TO PRODUCT MANUFACTURER INSTRUCTIONS FOR MINIMUM THICKNESS AND SURFACE PREPARATION. 3/4" MIN CLR ALL SIDES EXISTING CONCRETE VERIFY DEBRIS AND RESIDUE ARE REMOVED FROM BACK OF BAR . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A NO. DESCRIPTION Revisions: DATE 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES CONCRETE REPAIR DETAILS S2.10 TYPICAL CONCRETE REPAIR DETAIL - DETERMINING PERCENTAGE OF REBAR EXPOSURE 3" = 1'-0" 1 TYPICAL CONCRETE REPAIR DETAIL – CLEANING CONCRETE SURFACE AND REINFORCEMENT STEEL 3" = 1'-0" 2 NOTES: 1. NOTIFY ENGINEER OF REINFORCEMENT SECTION LOSS IS GREATER THAN 10%. EXISTING REINFORCEMENT TO REMAIN INTACT. CLEAN AND COAT EXPOSED STEEL WITH BONDING AGENT CONTAINING CORROSION INHIBITOR NOTES: 1. NOTIFY ENGINEER OF REINFORCEMENT SECTION LOSS IS GREATER THAN 10%. HORIZONTAL PATCHING MORTAR SEE MFR FOR S.S.D. SURFACE OR USE A BONDING AGENT SAWCUT PERIMETER OF REPAIR AREA STRAIGHT AND SQUARE LINES - TAPER EDGES TO FORM PLUG SEE MFR FOR S.S.D. SURFACE OR USE A BONDING AGENT SAWCUT PERIMETER OF REPAIR AREA STRAIGHT AND SQUARE LINES I N M R O F R F M F E R P Y T , S S E N K C H T I FORM AND POUR PATCHING MORTAR SURFACES SHALL BE CLEANED AND ROUGHENED TO MFR’S SPECIFICATION I S E R A V S S E N K C H T B A L S I ) F V I , I N M " 2 / 1 2 ( I S E R A V S S E N K C H T B A L S I ) F V I , I N M " 2 / 1 2 ( FULL DEPTH BOARD FORM BOTTOM SURFACE EXISTING REINFORCEMENT TO REMAIN INTACT. CLEAN AND COAT EXPOSED STEEL WITH BONDING AGENT CONTAINING CORROSION INHIBITOR HORIZONTAL PATCHING MORTAR SURFACES SHALL BE CLEANED AND ROUGHENED TO MFR’S SPECIFICATION I N M R O F R F M F E R P Y T , S S E N K C H T I SURFACES SHALL BE CLEANED AND ROUGHENED TO MFR’S SPECIFICATION VERTICAL PATCHING MORTAR D N U O R A R L C " 4 / 3 N A H T E R O M F I R A B D E S O P X E % 0 5 EXISTING CONCRETE EXISTING REINFORCEMENT TO REMAIN INTACT. CLEAN AND COAT EXPOSED STEEL WITH BONDING AGENT CONTAINING CORROSION INHIBITOR SEE MFR FOR S.S.D. SURFACE OR USE A BONDING AGENT EXTEND REPAIR TO EDGE IF REMAINING CONCRETE IS LESS THAN 2" SAWCUT PERIMETER OF REPAIR AREA STRAIGHT AND SQUARE LINES OVERHEAD PATCHING MORTAR VERTICAL OVERHEAD PATCHING MORTAR EXISTING CONCRETE PARTIAL DEPTH 3 SLAB REPAIR DETAIL 3" = 1'-0" 4 RISER REPAIR DETAIL 3" = 1'-0" NOTES: 1. AT EXISTING CONCRETE GIRDERS, BEAMS, AND JOISTS WHERE EXPOSED REINFORCEMENT BAR HAS LOST MORE THAN 10% IF THE BAR CROSS-SECTIONAL AREA DUE TO CORROSION (i.e., DEEP SURFACE RUST, SCALING, PITTING, OR DELAMINATION), PROVIDE ADDITIONAL BUNDLED REINFORCEMENT AS SHOWN. 2. CONTRACTOR SHALL DETERMINE LOST AREA OF STEEL AT EACH OCCURRENCE AND CONSERVATIVELY PROVIDE MORE STEEL THAN THE AREA LOST. REPAIR PATCH WIDTH REQUIRED LAP: 15" FOR #3 BARS 19" FOR #4 BARS 24" FOR #5 BARS LENGTH OF AFFECTED BAR REQUIRED LAP: 15" FOR #3 BARS 19" FOR #4 BARS 24" FOR #5 BARS A A EXISTING REINF ADD'L BUNDLED REBAR - SEE NOTE 2 ABOVE CONCRETE PATCH EXISTING CONCRETE EXISTING CONCRETE REPAIR PATCH WHERE REBAR HAS LOST > 10% OF BAR AREA 3/4" MIN BUNDLED REINFORCEMENT: EXISTING REBAR ADD'L BUNDLED REBAR ELEVATION VIEW SECTION A-A 5 GIRDER, BEAM, AND JOIST REINFORCEMENT AT CORRODED REBAR 3" = 1'-0" M A 8 3 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A 05/10/2024 NOTES: 1. ALL SPLICES FOR PREFORMED JOINT SEALS SHALL BE INSTALLED ACCORDING TO MANUFACTURER INSTRUCTIONS AND RECOMMENDED METHODS IN ORDER TO PROVIDE A CONTINUOUS SEAL. 3/4" (VIF) PRE-COMPRESSED SELF EXPANDING POLYURETHANE FOAM JOINT SEALANT WITH A TRAFFIC GRADE SILICONE COATING APPROVED PRODUCTS: - WABO H SEAL - EMSEAL DSM EXISTING CONCRETE OPTION B VERIFY SOUND CONCRETE AND A CLEAN JOINT PRIOR TO INSTALLATION OF JOINT SEAL - PREP CONCRETE SURFACES PER MANUFACTURER INSTRUCTIONS - CONCRETE REPAIRS WILL BE REQUIRED IF GROSS IRREGULARITIES, LOOSE CONCRETE, CRACKS, OR VOIDS ARE PRESENT ALONG SIDES OF JOINT - COORDINATE REPAIRS WITH EOR PRIOR TO JOINT SEAL INSTALLATION 3/4" (VIF) MOISTURE-INSENSITIVE MODIFIED EPOXY ADHESIVE APPLIED TO CONCRETE ON BOTH SIDES OF JOINT IN ADDITION TO ALL GROOVES ALONG SIDES OF JOINT MATERIAL APPROVED PRODUCTS: - WABO FOAMSEAL BONDER - APPROVED MANUFACTURER EPOXY NOTES: 1. MEASURE ALL VISIBLE CRACKS AT SURFACE AND REPAIR ENTIRE LENGTH OF CRACK IF ANY PORTION OF CRACK IS GREATER THAN 1/16" 2. SEE STRUCTURAL NOTES "JOINT SEALANT AT NON-STRUCTURAL CRACK REPAIR" FOR ADDITIONAL INFORMATION PRIMER ON SIDE WALLS OF ROUTED CRACK (ONLY WHERE RECOMMENDED BY MANUFACTURER) APPROVED JOINT SEALANT ROUTE CRACK 1/4" X 1/4" NOTES: 1. REMOVE PORTS AND CAP SEAL AFTER EPOXY HAS CURED. 2. SEE STRUCTURAL NOTES "EPOXY INJECTION AT STRUCTURAL CRACK REPAIR" FOR ADDITIONAL INFORMATION. 3. THIS REPAIR DETAIL IS ONLY REQUIRED AT CRACKS PENETRATING THROUGH THE ENTIRE SLAB AND RUNNING PARALLEL TO THE RISERS. THE TYPICAL CRACK REPAIR DETAIL (ROUTE AND SEAL) SHALL BE PROVIDED AT ALL OTHER CRACK LOCATIONS UNLESS NOTED OTHERWISE. EXISTING CONCRETE APPROVED PRE-FORMED LOW DENSITY CLOSED CELL ETHYLENE VINYL ACETATE (EVA) COPOLYMER FOAM - SIZE TO BE 25% LARGER THAN MEASURED JOINT OPENING APPROVED PRODUCTS: - WABO EVAZOTE U.V. - WILLSEAL CORESEAL OPTION A BOND BREAKER TAPE OR BACKER ROD AT BOTTOM OF JOINT EXISTING CONCRETE CRACK CRACK GREATER THAN 1/16” WIDTH EXISTING CONCRETE 1 PREFORMED EXPANSION JOINT SEAL 3" = 1'-0" 2 TYPICAL CRACK REPAIR DETAIL (1/16" WIDE AND LARGER) 3" = 1'-0" 3 EPOXY INJECTION AT STRUCTURAL CRACK REPAIR 3" = 1'-0" 4 TRAFFIC COATING CRACK TREATMENT 3" = 1'-0" SEAL EXPOSED SURFACE OF CRACK USING CAP SEAL PER MANUFACTURER RECOMMENDATIONS EXISTING CONCRETE B A L S R O L L A W I ) F V ( S S E N K C H T I DETAIL COATS(S) 2” MIN EITHER SIDE OF CRACK - MIN 30 DRY MILS ROUTED AND SEALED PER TYPICAL CRACK REPAIR DETAIL (1/16" AND LARGER) ELASTOMERIC TRAFFIC COATING SYSTEM CRACK LESS THAN 1/16” WIDTH INSTALL INJECTION PORTS IN ACCORDANCE WITH MANUFACTURER RECOMMENDATIONS, TYP SEAL EXPOSED SURFACE OF CRACK USING CAP SEAL PER MANUFACTURER RECOMMENDATIONS M A 9 3 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A NO. DESCRIPTION Revisions: DATE 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES CONCRETE REPAIR DETAILS S2.11 05/10/2024 SUMMARY: CONCRETE SPALL WHERE REBAR HAS NOT BEEN EXPOSED. REPAIR NOTES: PROVIDE CONCRETE PATCH PER NOTES AND DETAILS ON S2.10. SUMMARY: CONCRETE SPALL WITH EXPOSED REBAR CAUSED BY POOR CONCRETE CONSOLIDATION AND/OR INADEQUATE CONCRETE COVER. CARBONATION OF THE CONCRETE AND EXPOSURE TO MOISTURE OVER TIME HAS CAUSED THE REBAR TO RUST AND SWELL, RESULTING IN CORROSION OF THE REBAR AND CONCRETE SPALLING. REPAIR NOTES: PROVIDE CONCRETE PATCH PER NOTES AND DETAILS ON S2.10. SUMMARY: CONCRETE CRACKS ARE VISIBLE AND APPEAR TO BE INITIATING A SPALL IN SOME CASES. CARBONATION OF THE CONCRETE AND EXPOSURE TO MOISTURE OVER TIME HAS CAUSED THE REBAR TO RUST AND SWELL, RESULTING IN CORROSION OF THE REBAR AND CRACKS FORMING. REPAIR NOTES: AFTER SOUNDING CONCRETE DURING DELAMINATION SURVEY, CRACKS SHALL BE REPAIRED PER DETAILS 2/S2.11 AND 3/S2.11. WHERE CONCRETE HAS SPALLED NEAR THE CRACKS INDICATED, PATCH CONCRETE PER NOTES AND DETAILS ON S2.10. CRACKS ADJACENT TO THE SPALLS SHALL ALSO BE REPAIRED PER 2/S2.11 AND 3/S2.11. 1 CONCRETE SPALL 3/4" = 1'-0" 2 EXPOSED REBAR WITH CONCRETE SPALLING 3/4" = 1'-0" 3 CRACKING IN CONCRETE SLAB 3/4" = 1'-0" SUMMARY: CLEAR COVER WAS INADEQUATE OR WEAR AND TEAR HAS EXPOSED PORTIONS OF REBAR THAT ARE VISIBLE AT SURFACE. REPAIR NOTES: WHERE SURROUNDING CONCRETE IS INTACT, PAINT EXPOSED REBAR USING PRIMER WITH CORROSION INHIBITOR INTENDED FOR PPLICATION ON STEEL AND FOR EXTERIOR EXPOSURE. IF TRAFFIC COATING WILL BE APPLIED, PATCH AS NECESSARY FOR SMOOTH SURFACE PER MANUFACTURER INSTRUCTIONS, GRIND HIGH POINTS AS REQUIRED TO BE FLUSH WITH TOP OF CONCRETE, AND APPLY PRIMER WITH CORROSION INHIBITOR TO EXPOSED STEEL PRIOR TO APPLICATION OF TRAFFIC COATING SYSTEM. SUMMARY: POOR CONSOLIDATION OF CONCRETE RESULTED IN VOIDS, EXPOSED REBAR IN SOME CASES, AND A WEAK POINT FOR WATER INTRUSION AND FURTHER STRUCTURAL DETERIORATION REPAIR NOTES: CHIP OUT LOOSE AGGREGATE AND TREAT EXPOSED PORTIONS OF REBAR PRIOR TO PATCHING PER NOTES AND DETAILS ON S2.10. SUMMARY: PREVIOUS ATTEMPTS TO PATCH AND REPAIR CONCRETE HAVE NOT LASTED AND REQUIRE REPLACEMENT IN ORDER TO PROTECT THE STRUCTURAL INTEGRITY OF THE CONCRETE. REPAIR NOTES: FULLY REMOVE ALL LOOSE PATCHES TO SOUND CONCRETE AND APPLY NEW PATCH PER NOTES AND DETAILS ON S2.10. M A 9 3 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A 4 EXPOSED REBAR WITH NO SPALLING 3/4" = 1'-0" 5 POOR CONSOLIDATION 3/4" = 1'-0" 6 FAILING PATCHES 3/4" = 1'-0" SUMMARY: HANDRAIL AND FENCE CONNECTION PIPES HAVE RUSTED DUE TO WATER INFILTRATION, INADEQUATE COVER, AND LACK OF MAINTENANCE. THE INTEGRITY OF THE RAILING IS COMPROMISED IN MANY LOCATIONS DUE TO SCALING AND / OR PITTING OF THE STEEL AND THE CONCRETE AT THE BASE CONNECTION HAS CRACKED AND/OR SPALLED IN MANY LOCATIONS. REPAIR NOTES: CONTRACTOR SHALL EVALUATE THE POSSIBILITY OF REPAIRING RAILINGS AND ONLY REPLACING THE PORTION OF PIPE NEAR THE BASE CONNECTION. A CONTINUOUS SPLICE WELD WOULD BE REQUIRED APPROXIMATELY 6" ABOVE THE CONCRETE. IF COST PROHIBITIVE, THE ENTIRE RAILING SHOULD BE REPLACED. AT LOCATIONS WHERE ONLY SURFACE RUST IS PRESENT AND CONCRETE IS INTACT, CLEAN EXPOSED SURFACE WITH WIRE BRUSH AND APPLY TUFFTEX RUST REHAB (1ST COAT) AND MATCHING YELLOW PAINT (2ND COAT, REF. ARCH SPEC.) AT BASE CONNECTIONS WHERE CONCRETE IS DAMAGED AND/OR CRACKED, SOUND AND REMOVE LOOSE/DAMAGED CONCRETE. PROVIDE ADEQUATE CLEARANCE ALL SIDES OF PIPE FOR APPLYING NEW CONCRETE PATCH (6" MINIMUM PATCH THICKNESS EACH SIDE OF PIPE PARALLEL TO WALL, MATCH THICKNESS OF EXISTING WALL). PATCH PER "CONCRETE PATCHING MORTAR" STRUCTURAL NOTES ON S0.03 TO RESTORE PROFILE OF WALL/CURB. AT ENDS OF WALLS, ADDITIONAL REINFORCEMENT IS ANTICIPATED TO ANCHOR THE NEW PATCH TO THE EXISTING CONCRETE TO REMAIN. COORDINATE WITH E.O.R. BY SUBMITTING AN RFI INCLUDING PHOTOS OF EACH END CONDITION AFTER LOOSE CONCRETE IS REMOVED ALONG WITH ANY OTHER QUESTIONABLE CONDITIONS. EXISTING PIPE RAILING -CUT AND REMOVE ALL STEEL WITH SIGNS OF SCALING, PITTING, AND / OR LOSS OF SECTION NEW BASE RAILING (WHERE REQ'D DUE TO CORROSION) -PROVIDE SLEEVE AS SHOWN OR MATCH DIAMETER AND PROVIDE PARTIAL PENETRATION WELD ALL AROUND WITH BEVELED EDGES POTENTIAL #3 DOWELS DEPENDING ON GEOMETRY OF PATCH (COORD. WITH EOR AFTER REMOVING ALL EMBEDDED CORRODED RAILINGS) 1/4 " 3 P A L " 6 D E B M E 1/4 " 3 P A L " 2 " 6 D E B M E EXISTING PIPE RAILING -CUT AND REMOVE ALL STEEL WITH SIGNS OF SCALING, PITTING, AND / OR LOSS OF SECTION NEW BASE RAILING (WHERE REQ'D DUE TO CORROSION) -PROVIDE SLEEVE AS SHOWN OR MATCH DIAMETER AND PROVIDE PARTIAL PENETRATION WELD ALL AROUND WITH BEVELED EDGES #3 "U" DOWEL AT END OF WALL 6" MIN. 6" MIN. 6" MIN. HANDRAIL REPAIR AT MIDDLE OF WALL (ELEVATION) HANDRAIL REPAIR AT END OF WALL (ELEVATION) HANDRAIL AND FENCE REPAIRS AT ADA PLATFORMS AND FRONT WALL 3/4" = 1'-0" 7 . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A NO. DESCRIPTION Revisions: DATE 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES TYPICAL CONCRETE REPAIR PHOTOS S2.12 05/10/2024 CONCRETE COLUMN, TYP. SCOREBOARD SEE 3/S2.13 FOR SPALLS AND EXPOSED REBAR LOCATED BEHING SCREEN CLEAN AND PAINT REBAR LADDER RUNGS WHERE SURFACE RUST IS VISIBLE USING TUFFTEX RUST REHAB (1ST COAT) AND EXTERIOR EPOXY PAINT (REF. ARCH.) SEE 3/S2.13 FOR SPALLS AND EXPOSED REBAR LOCATED BEHING SCREEN NOTE: CONCRETE REPAIR QUANTITIES ARE INCLUDED IN THE "BASE BID (PROJECT TOTAL QUANTITIES)" TABLE ON S0.03 M A 2 4 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A 2 CONCRETE SPALLING AT BACK OF SCOREBOARD 3/4" = 1'-0" PATCH SPALLED AREA NEAR TOP OF WALL PER DETAILS ON S2.10 SEE 2/S2.13 FOR TYPICAL SPALLS AND EXPOSED REBAR LOCATED ABOVE BOTTOM CONCRETE BEAM PATCH SPALLED AREA NEAR TOP OF WALL PER DETAILS ON S2.10 N 1 SCOREBOARD REPAIR PLAN 3/4" = 1'-0" 3 CONCRETE SPALLING AT FRONT OF SCOREBOARD 3/4" = 1'-0" SUMMARY: CONCRETE SPALL WITH EXPOSED REBAR CAUSED BY POOR CONCRETE CONSOLIDATION AND/OR INADEQUATE CONCRETE COVER. CARBONATION OF THE CONCRETE AND EXPOSURE TO MOISTURE OVER TIME HAS RESULTED IN CORROSION OF THE REBAR AND CONCRETE SPALLING. REPAIR NOTES: PROVIDE CONCRETE PATCH PER NOTES AND DETAILS ON S2.10. SUMMARY: CONCRETE SPALL WITH EXPOSED REBAR CAUSED BY POOR CONCRETE CONSOLIDATION AND/OR INADEQUATE CONCRETE COVER. CARBONATION OF THE CONCRETE AND EXPOSURE TO MOISTURE OVER TIME HAS RESULTED IN CORROSION OF THE REBAR AND CONCRETE SPALLING. REPAIR NOTES: PROVIDE CONCRETE PATCH PER NOTES AND DETAILS ON S2.10. . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A NO. DESCRIPTION Revisions: DATE 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES SCOREBOARD REPAIR PLAN AND PHOTOS S2.13 05/10/2024 'Ldh' TENSION DEVELOPMENT LENGTH (EMBEDMENT LENGTH) FOR STANDARD END HOOKS (GRADE 60 UNCOATED BARS) NORMAL WEIGHT CONCRETE LDH 2" MIN. COVER (*) STANDARD 90° HOOK SIDE COVER > 2 1/2" 2" MIN. COVER ON EXPOSED SURFACES INCREASE ldh DIMENSION IF NECESSARY (*) LDH STANDARD 180° HOOK SIDE COVER > 2 1/2" f'c=3000 PSI f'c=4000 PSI f'c=5000 PSI f'c=6000 PSI f'c=8000 PSI LDH LDH LDH LDH LDH BAR SIZE #3 #4 #5 #6 #7 #8 #9 #10 #11 6" 8" 10" 12" 14" 16" 18" 20" 22" 6" 7" 9" 10" 12" 14" 15" 17" 19" 6" 6"* 8" 9" 11" 12" 14" 15" 17" 6" 6"* 7" 8" 10" 11" 13" 14" 16" 6" 6"* 6"* 7"* 9" 10" 11" 12"* 14"* NOTES: 1. WHEN EITHER SIDE OR END COVER IS SMALLER THAN 2 1/2", MULTIPLY "LDH" BY 1.4. 2. END CONCRETE COVER (90° HOOKS) > 2". 3. * FOR 180° HOOKS AT RIGHT ANGLES TO EXPOSED SURFACES, 2" MINIMUM COVER TO TAIL SHALL BE PROVIDED. 1 LAP SPLICE SCHEDULE 3/4" = 1'-0" TENSION LAP SPLICES - CLASS B - TOP & BOTTOM BARS (GRADE 60 UNCOATED BARS) NORMAL WEIGHT CONCRETE 'Ld' TENSION DEVELOPMENT LENGTH (GRADE 60 UNCOATED BARS) NORMAL WEIGHT CONCRETE f'c = 3000 PSI f'c = 4000 PSI f'c = 5000 PSI f'c = 6000 PSI f'c = 8000 PSI f'c = 3000 PSI f'c = 4000 PSI f'c = 5000 PSI f'c = 6000 PSI f'c = 8000 PSI TOP BOTTOM TOP BOTTOM TOP BOTTOM TOP BOTTOM TOP BOTTOM LD TOP LD BOTTOM LD TOP LD BOTTOM LD TOP LD BOTTOM LD TOP LD BOTTOM LD TOP LD BOTTOM BAR SIZE #3 #4 #5 #6 #7 #8 #9 #10 #11 28" 37" 47" 56" 81" 93" 105" 118" 131" 22" 29" 36" 43" 63" 72" 81" 91" 101" 24" 32" 40" 48" 70" 80" 91" 102" 113" 19" 25" 31" 37" 54" 62" 70" 79" 87" 22" 29" 36" 43" 63" 72" 81" 91" 101" 17" 22" 28" 33" 49" 55" 63" 70" 78" 20" 26" 33" 40" 58" 66" 74" 83" 93" 16" 20" 25" 31" 44" 51" 57" 64" 71" 17" 23" 29" 34" 50" 57" 64" 72" 80" 16" 18" 22" 26" 38" 44" 49" 56" 62" NOTES: 1. TABULATED VALUES ARE APPLICABLE ONLY IF CLEAR SPACING OR BARS BEING DEVELOPED OR SPLICED IS NOT LESS THAN 'db', CLEAR COVER IS NOT LESS THAN 'db', AND STIRRUPS OR TIES THROUGHOUT 'ld' IS NOT LESS THAN CODE MINIMUM OR CLEAR SPACING OF BARS BEING DEVELOPED OR SPLICED IS NOT LESS THAN 2X 'db' AND CLEAR COVER IS NOT LESS THAN 'db'. WHERE db IS THE NOMINAL DIAMETER OF THE BAR. 2. 'TOP' BARS ARE HORIZONTAL REBAR WITH MORE THAN 12" OF FRESH CONCRETE CAST BELOW THE BARS AT THE END DEVELOPMENT LENGTH. 3. FOR LIGHT WEIGHT CONCRETE, MULTIPLY THE TABULATED VALUES BY 1.3. 4. FOR EPOXY COATED BARS, MULTIPLY TABULATED VALUES BY THE RATIO OF THE REINFORCEMENT YIELD STRENGTH DIVIDED BY 60 KSI. 5. FOR CLASS "A" SPLICE USE VALUE AS NOTED IN THE TENSION DEVELOPMENT LENGTH TABLE. BAR SIZE #3 #4 #5 #6 #7 #8 #9 #10 #11 22" 29" 36" 43" 63" 72" 81" 91" 101" 17" 22" 28" 33" 48" 55" 62" 70" 78" 19" 25" 31" 37" 54" 62" 70" 79" 87" 15" 19" 24" 29" 42" 48" 54" 61" 67" 17" 22" 28" 33" 49" 55" 63" 70" 78" 13" 17" 22" 26" 37" 43" 48" 54" 60" 15" 20" 25" 31" 44" 51" 57" 64" 71" 12" 16" 20" 24" 34" 39" 44" 49" 55" 13" 18" 22" 26" 38" 44" 49" 56" 62" 12" 14" 17" 20" 30" 34" 38" 43" 48" NOTES: 1. TABULATED VALUES ARE APPLICABLE ONLY IF CLEAR COVER OF BARS BEING DEVELOPED OR SPLICED IS NOT LESS THAN 'db', AND STIRRUPS OR TIES THROUGHOUT 'LD' IS NOT LESS THAN CODE MINIMUM, OR CLEAR SPACING OR BARS BEING DEVELOPED OR SPLICED IS NOT LESS THAN 2X 'db' AND CLEAR COVER IS NOT LESS THAN 'db'. WHERE db IS THE NIMINAL DIAMETER OF THE BAR. 2. 'TOP' BARS ARE HORIZONTAL REBAR WITH MORE THAN 12" OF FRESH CONCRETE CAST BELOW THE BARS AT THE DEVELOPMENT LENGTH. 3. FOR LIGHT WEIGHT CONCRETE, MULTIPLY TABULATED VALUES BY 1.3. 4. FOR EPOXY COATED BARS, MULTIPLY TABULATED VALUES BY 1.5 FOR BOTTOM BARS, AND BY 1.3, FOR TOP BARS. 5. FOR REINFORCEMENT OTHER THAN GRADE 60, MODIFY THE TABULATED VALUES BY THE RATIO OF THE REINFORCEMENT YIELD STRENGTH DIVIDED BY 60KSI. 'Ldc' COMPRESSION DEVELOPMENT LENGTH AND COMPRESSION LAP SPLICES (GRADE 60 UNCOATED BARS) NORMAL WEIGHT CONCRETE f'c ≥ 3000 PSI MINIMUM LAP SPLICE LDC STANDARD LAP WITH COLUMN SPIRALS BAR SIZE #3 #4 #5 #6 #7 #8 #9 #10 #11 9" 11" 14" 17" 20" 22" 25" 28" 31" 12" 15" 19" 23" 26" 30" 34" 38" 42" 12" 12" 14" 17" 20" 23" 25" 29" 32" NOTES: 1. STANDARD LAP SPLICE LENGTH FOR COMPRESSION BARS = 30 BAR DIAMTERS, BUT NOT LESS THAN 12". 2. WHEN BARS OF DIFFERENT SIZE ARE LAP SPLICED, SPLICE LENGTH SHALL BE THE LARGER OF LDC. 3. SPIRALS SHALL CONFORM TO ACI 7.10.4 & 10.9.3 ° 5 3 1 6 d O 4 " R M I N . D BAR #3 #4 #4 2 1/2" D 2" 2 1/2" #6-#8 6d D 1 1 FOR STIRRUPS AND TIES D d D D D 4d OR 2 1/2" MIN. d = BAR DIAMETER D = 6d FOR #3 THRU #8 D = 8d FOR #9 THRU #11 1 6 d 2 1 . I N M " 2 1 FOR REINFORCING BARS OFFSET NOTES: 1. WHERE 90 DEGREE HOOKS ARE SCHEDULED OR DETAILED FOR TOP OR BOTTOM BARS, CORNER BARS MAY BE OMITTED. 2. MATCH SIZE, LOCATION AND NUMBER OF HORIZONTAL BEAM AND WALL BARS, EXCEPT THAT WHERE THERE ARE MORE THAN 2 TOP OR BOTTOM BARS, ONLY THE INSIDE AND OUTSIDE BARS MUST BE MATCHED. NOTE: PROVIDE BARS AS SHOWN AT ALL RE-ENTRANT CORNERS INCLUDING OPENINGS, ISOLATION JOINTS, AND CONSTRUCTION JOINTS. 30 BAR DIAMETERS EACH LEG TYPICAL CORNER BARS EACH FACE TO MATCH SMALLER BAR AT INTERSECTION - PROVIDE CORNER BARS SHOWN AT TOP, BOTTOM AND INTERMEDIATE HORIZONTAL BARS CORNER BARS EACH FACE TO MATCH TOP, BOTTOM AND INTERMEDIATE BARS IN DISCONTINUOUS MEMBER STOP DETAILED REINF. 2" SHORT OF FORM - TYPICAL CORNER BARS PLAN VIEW S R E T E M A D R A B 0 3 I I L A C P Y T G E L H C A E 3" C L R. 3" PLAN VIEW EDGE OF SLAB (2) #4 X 4'-0" LOCATED 2" BELOW TOP OF SLAB AT ALL RE-ENTRANT CORNERS NOTE: PROVIDE AT BASE OF ALL INTERIOR STAIRS. STAIR STRINGER L3-1/2"X3-1/2"X1/4" BTWN. STAIR STRINGERS 1/4" CLOSURE PLATE " 8 (2) #4 CONT. 1' - 0" 3/4" Ø EXP. BOLTS (MIN. 4" EMBED) 2 BAR BENDING DIAGRAMS 3/4" = 1'-0" 3 CORNER BARS AT WALL OR GRADE BEAM INTERSECTION 3/4" = 1'-0" 4 RE-ENTRANT CORNER SLAB BARS 3/4" = 1'-0" 5 THICKENED SLAB AT STAIR CONNECTION 3/4" = 1'-0" M A 3 4 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A NO. DESCRIPTION Revisions: DATE 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES TYPICAL CONCRETE DETAILS S3.00 05/10/2024 PIER NOTES: 1. TEMPORARY STEEL CASING MAY BE REQUIRED DURING PIER DRILLING OPERATIONS. PRIOR TO PLACEMENT OF CONCRETE, ANY SEEPAGE WATER SHALL BE REMOVED FROM THE PIER HOLES. SPECIAL CONSTRUCTION PROCEDURES IN ACCORDANCE WITH ACI 336.1-01 AND SPECIFICATIONS SHALL BE FOLLOWED DURING EXTRACTION OF THE CASING AND DURING CONCRETE PLACEMENT. 2. CONTRACTOR SHALL INCLUDE IN BID DOCUMENTS, UNIT-COSTS FOR CASING IF REQUIRED AND UNIT-COST FOR GREATER OR LESSER DEPTH OF DRILLING FOR EACH PIER SIZE. SEE PLAN FOR SECTIONS " 3 HOOKED DOWELS TO MATCH PIER REINF. SIZE AND QUANTITY -PROVIDE LAP PER SCHEDULE TO PIER SEE PLAN (3) TIES @ TOP OF PIER, TYP. C L R . " 3 ESTIMATED BEARING GRAY LIMESTONE PER GEOTECHNICAL REPORT = APPROXIMATELY 24'-0" BELOW GRADE AT TIME OF EXPLORATION M U T A R T S G N R A E B O T N I I I N O T A R T E N E P E L U D E H C S E E S NOTE: NO CONSTRUCTION JOINTS SHALL BE ALLOWED IN CONCRETE WALL U.N.O. ON PLAN 2'-0" #4 DOWEL " 0 - ' 2 @ 12" O.C. T.O. PAVING = REF. CIVIL T.O. WALL = 481'-4" REINF. WALL W/ VERT. #5 EACH FACE @ 12" O.C. & HORIZ. #5 @ 12" O.C. EACH FACE 1' - 0" 5 S3.01 FINISH GRADE REF. CIVIL " 0 - ' 1 . I N M B.O. WALL = T.O. PIER (SEE PLAN) M A 4 4 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A 2 4 1 8 " L " L A A P P F F O O R R # # 4 3 CONCRETE PIER - SEE PLAN FOR PIER TYPE & SCHEDULE FOR REINFORCEMENT d L . R L C " 3 STEEL COLUMN BEYOND SITE PAVING -REF. CIVIL PILASTER BEYOND -SEE 5/S3.01 FOR REINF. FRENCH DRAIN REF. CIVIL SOIL RETAINER AND VOID CARTONS -SEE STR. NOTES PIER SCHEDULE PIER TYPE (SEE PLAN) PIER SIZE VERTICAL REINF. PIER TIES PENETRATION INTO BEARING STRATUM CALCULATED PIER CAPACITY (KIPS) UPLIFT CAPACITY (KIPS) P1 P2 24" Ø PIER 24" Ø PIER (8) #6 (8) #6 #3 @ 12" O.C. #3 @ 12" O.C. 4 FT 8 FT 250 377 75 150 3/4" CHAMFER ALL EXPOSED EDGES -TYP STEEL COLUMN & BASEPLATE - SEE PLAN 1/2" COMPRESSIBLE FILL SITE PAVING - REF CIVIL CONCRETE PLINTH - REINF W/ (12) #6 VERTS, #3 TIES (3) TOP, REMAINING AT 12" OC MAX PIER DOWELS - SEE PIER DETAIL PIER - SEE PLAN 24"x24" CONCRETE COLUMN WRAP - REINF W/ (8) #5 VERTS, #3 TIES @ 12" OC, (2) TIES TOP TOC = SEE PLAN " 0 - ' 2 T.O. PIER = SEE PLAN VOID FORMS AND SOIL RETAINERS - SEE STRUCTURAL NOTES SITE PAVING - REF CIVIL GRADE BEAM - REINF W/ (2) #6 TOP & BOTTOM - #3 STIRRUPS AT 10" OC " 0 - ' 2 TOC = SEE PLAN T.O. PIER = SEE PLAN SEE PLAN VOID FORMS AND SOIL RETAINERS - SEE STRUCTURAL NOTES 1 STRAIGHT SHAFT PIER SECTION AND SCHEDULE 3/4" = 1'-0" 3 TYPICAL GRADE BEAM DETAIL 3/4" = 1'-0" 2'-6" SQUARE U.N.O. ON PLAN 2 TYPICAL PILASTER DETAIL 3/4" = 1'-0" 1' - 6" 1' - 6" PILASTER -REINF. W/ (12) VERT. #6, #3 TIE SETS @ 12" O.C. (3 TIE SETS AT TOP OF PILASTER) " 6 - ' 1 CONCRETE WALL -REINF. TO RUN CONTINOUS THRU PILASTER -REINF. NOT SHOWN FOR CLARITY FORM UP BOTTOM OF BEAM AND REMOVE FORMS BEFORE BACKFILLING OR FILL VOID WITH CARTON FORMS PROTECTED BY VAPOR RETARDER OVER PROTECTION BOARD SECURE SOIL RETAINER TO BEAM OR WALL WITH ADHESIVE FOR FASTENING BY MECHANICAL MEANS @ 18" O.C. A WASHER SHALL BE USED WITH MECHANICAL FASTENERS AND SHALL BE INSTALLED 5" (MIN.) FROM BOTTOM OF BEAM OR WALL VOID SPACE 1/2" THICK HIGH DENSITY POLYPROPYLENE SOIL RETAINER ("BACKFILL RETAINER") BY SUREVOID, EMBED INTO CLAY TO OBTAIN FIRM SEATING NOTES: 1. FORM VOID SPACE WITH SOIL RETAINERS UNDER ALL 2. STRUCTURAL CONCRETE PIER CAPS, PILASTERS, GRADE BEAMS, AND WALLS BELOW GRADE. INSTALL SOIL RETAINERS IN STRICT ACCORDANCE WITH MANUFACTURERS RECOMMENDATIONS AND AS FOLLOWS: A. PLACE BASE OF SOIL RETAINER IN A 3" DEEP TRENCH CUT IN UNDISTURBED SOIL OR COMPACTED FILL. TRENCHES SHALL BE LOCATED 4" FROM OUTSIDE AND INSIDE FACE OF GRADE BEAM OR WALL PANEL. B. STARTING AT END OF BEAM OR WALL PANEL. LAY BOTTOM FLANGE OF SOIL RETAINER IN TRENCH AND LEAN FLAT SIDE AGAINST BEAM OR WALL PANEL. OVERLAP SIDE FLANGES AT LEAST 1" TO PROVIDE A CONTINUOUS SEAL. C. CUT BLOCK TO FIT ENDS OF BEAMS OR WALL PANELS. MITER CUT OR BEND RETAINERS AT CORNERS. CUT LENGTHS LESS THAN 1'-0" IN LENGTH SHALL NOT BE USED. D. PLACE BACKFILL AS SPECIFIED AFTER COMPLETION OF SOIL RETAINER INSTALLATION. TAKE NECESSARY PRECAUTIONS TO PROTECT SOIL RETAINERS FROM DAMAGE FROM COMPACTION EQUIPMENT. 3. STORE RETAINERS FLAT AND PROTECTED FROM DIRECT SUNLIGHT TO AVOID WARPAGE. . I N M " 6 " X - ' X " 3 NO. DESCRIPTION Revisions: DATE 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES TYPICAL FOUNDATION DETAILS S3.01 4 RETAINING WALL AT EXTERIOR STAIR 3/4" = 1'-0" 5 VERT. PILASTER REINFORCEMENT 3/4" = 1'-0" 6 FOUNDATION VOID SPACE DETAIL 3/4" = 1'-0" . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A 05/10/2024 NOTES: 1. REFER TO CIVIL DRAWINGS FOR ALL TOP OF PAVING (TW) AND FINISH GRADE (BW) ELEVATIONS. 2. REFER TO CIVIL DRAWING FOR SITE PAVING DESIGN. 3. FOOTINGS SHALL BEAR AT A CONSISTANT ELEVATION. STEP FOOTINGS AS NEEDED TO MAINTAIN SPECIFIED MAXIMUM WALL HEIGHTS. REFER TO TYPICAL DETAILS FOR FOOTING STEPS. SITE PAVING - REF CIVIL 2'-0" " 0 - ' 2 #4 X DWL @ 18" O.C. T.O. PAVING (TW)= REF CIVIL T.0. WALL = " 8 REINF. WALL W/ VERT. #5 EACH FACE & HORIZ. #4 @ 12" O.C. EACH FACE, TYP. 10" . X A M " 0 - ' 8 FINISH GRADE (BW) REF. CIVIL T.O. FOOTING = 6" " 0 - ' 1 . I N M " 0 - ' 1 #5 @ 12" O.C. TOP AND BOTTOM, TYP. 10" SITE PAVING - REF CIVIL FRENCH DRAIN REF. CIVIL 6" 6" 8" T.O. PAVING (TW)= REF CIVIL T.0. WALL = VARIES FINISH GRADE (BW) REF. CIVIL T.O. FOOTING " 8 " 0 - ' 1 . I N M " 0 1 . X A M " 6 - ' 3 NOTE: CONTRACTION JOINT SPACING NOT TO EXCEED 30'-0" RUSTICATION - REF ARCH CONT WATERSTOP EXPOSED FACE Q E Q E 3/4" Ø X 12" PLASTIC SLEEVE AS MANUFACTURED BY GREENSTREAK INC. WALL REINF WALL REINF - SEE DETAIL - SEE SCHEDULE I S E R A V NOTE: CONTROL JOINT SPACING NOT TO EXCEED 30'-0". ALIGN WITH JOINTS IN MASONRY FINISHES PER ARCHITECTURAL. MASTIC CAULKING EXPOSED FACE 3/4" Ø X 2'-0" SMOOTH STAINLESS STEEL DOWELS @ 12" O.C. 2" CLR TYP THIS SIDE OF WALL PLACED FIRST CONSTRUCTION JOINT NOTE: EXPANSION JOINT SPACING NOT TO EXCEED 90'-0" 3/4" E.J. 11" 1" WALL REINF WALL REINF - SEE DETAIL - SEE SCHEDULE RUSTICATION - REF ARCH EXPOSED FACE Q E Q E CUT ALTERNATE HORIZ REINF AT CONTROL JOINT 3/4" Ø X 2'-0" SMOOTH STAINLESS STEEL DOWELS @ 12" O.C. 2" CLR TYP 3/4" Ø X 12" PLASTIC SLEEVE AS MANUFACTURED BY GREENSTREAK INC. WALL REINF. WALL REINF. - SEE SCHEDULE - SEE DETAIL I S E R A V THIS SIDE OF WALL PLACED FIRST 1" COMPRESSIBLE PLUG 3/4" PRE-MOLDED JOINT FILLER 1 SITE RETAINING WALL SECTION 3/4" = 1'-0" CONT. #4 @ 12" TOP AND BOTTOM, TYP. 2' - 6" RETAINING WALL CONTRACTION JOINT 3/4" = 1'-0" 2 3 RETAINING WALL CONTROL JOINT 3/4" = 1'-0" 4 RETAINING WALL EXPANSION JOINT 3/4" = 1'-0" NOTES: 1. REFER TO CIVIL DRAWINGS FOR ALL TOP OF PAVING (TW) AND FINISH GRADE (BW) ELEVATIONS. 2. REFER TO CIVIL DRAWING FOR SITE PAVING DESIGN. 3. FOOTINGS SHALL BEAR AT A CONSISTANT ELEVATION. STEP FOOTINGS AS NEEDED TO MAINTAIN SPECIFIED MAXIMUM WALL HEIGHTS. REFER TO TYPICAL DETAILS FOR FOOTING STEPS. SITE PAVING - REF CIVIL T.O. PAVING (TW)= REF CIVIL T.0. WALL = 10" 10" T.O. PAVING (TW)= REF CIVIL T.0. WALL = " 8 REINF. WALL W/ VERT. #5 EACH FACE & HORIZ. #4 @ 12" O.C. EACH FACE, TYP. . X A M " 0 - ' 8 FINISH GRADE (BW) REF. CIVIL T.O. FOOTING = 6" " 0 - ' 1 . I N M " 0 - ' 1 #5 @ 12" O.C. TOP AND BOTTOM, TYP. CONT. #4 @ 12" TOP AND BOTTOM, TYP. FRENCH DRAIN REF. CIVIL 2' - 6" 8" 6" T.O. PAVING (TW)= REF CIVIL T.0. WALL = VARIES . X A M " 0 - ' 3 " 0 1 FRENCH DRAIN REF. CIVIL 2'-0" " 0 - ' 2 #4 X DWL @ 18" O.C. T.O. PAVING (TW)= REF CIVIL T.0. WALL = VARIES " 8 X A M " 6 - ' 3 FINISH GRADE (BW) REF. CIVIL T.O. FOOTING = " 0 - ' 1 . I N M " 0 1 2' - 6" M A 5 4 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A 5 STEP IN RETAINING WALL FOOTING 3/4" = 1'-0" 6 SITE RETAINING WALL SECTION 3/4" = 1'-0" 2'-0" " 0 - ' 2 #4 X DWL @ 18" O.C. SITE PAVING -REF. CIVIL SEE 1/S3.02 FOR WALL AND FOOTING REINFORCING 10" FOOTING REINF - SEE DETAIL I S E R A V 1'-0" 1'-0" #4 X @ 12" O.C. 3 1/2" X 1 1/2" CONT. KEY . X A M " 0 - ' 2 I S E R A V 1 2 1' - 6" REINF. W/ #3 @ 12" O.C. EACH WAY #4 NOSING BAR, TYP. #4 DOWELS @ 12" O.C. -PROVIDE STD HOOK AT BOTTOM OF FOOTING FINISH GRADE = REF. CIVIL T.O. FOOTING = " 0 - ' 1 . I N M " 0 - ' 1 7 CONCRETE STAIR AND WALL SECTION 3/4" = 1'-0" . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A NO. DESCRIPTION Revisions: DATE 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES SITE RETAINING WALL DETAILS S3.02 05/10/2024 PIER PIER EQ 4 11 1/2" SEE PLAN 7 5/8" SEE PLAN 1' - 2 7/8" 9 1/2" 11 3/4" 6' - 3 3/16" 11 3/4" NOTES: 1. SUMP PIT LOCATION TO BE COORDINATED WITH ELEVATOR MANUFACTURER. SEE TYPICAL DETAIL FOR SUMP PIT REINFORCEMENT. 2. WATERPROOFING IS NOT SHOWN. REFER TO ARCHITECT. B SEE 1/S3.03 FOR INFO NOT SHOWN 3.2 EQ 1' - 3" 2'-0" " 0 - ' 2 #4 X @ 12" OC " 6 STEEL COLUMN - SEE PLAN 6" SLAB ON FILL - REINF W/ #4 @ 2 12" OC EACH WAY " d L " " d L " " 8 TOC = SEE PLAN 4 1/2" 1' - 4" 4 3/8" 1' - 0" " d L " " d L " " 6 1' - 3" " 6 TOC = SEE PLAN A I Y F R E V R F M / W CMU WALL BEYOND ANGLE BY OTHERS - ATTACH USING 1/2" Ø THREADED RODS AT 12" OC EMBEDDED 3 1/2" INTO CONCRETE USING HILTI HIT-HY 200 EPOXY TOC = SEE PLAN SITE PAVING - REF CIVIL 3" T.O. PIER = SEE PLAN STEEL COLUMN AND COLUMN WRAP BEYOND - SEE PLAN TOC = SEE PLAN 6" SLAB ON FILL - REINF W/ @4 # 12" OC EACH WAY 2'-0" " 0 - ' 2 #4 X @ 12" OC TOC = SEE PLAN FLOWABLE FILL " 0 - ' 2 T.O. PIER = SEE PLAN 1' - 3" 3" NOTES: 1. SUMP PIT LOCATION TO BE COORDINATED WITH ELEVATOR MANUFACTURER. SEE TYPICAL DETAIL FOR SUMP PIT REINFORCEMENT. 2. WATERPROOFING IS NOT SHOWN. REFER TO ARCHITECT. 8" CMU WALL - SEE SCHEDULE CMU DOWELS TO MATCH TYPICAL REINF SIZE AND SPACING VERT CONCRETE WALL - REINF W/ #5 @ 12" OC VERT EACH FACE & #4 @ 12" OC HORIZ EACH FACE -TYP PILASTER BEYOND - REINF W/ #6 @ 12" OC FULL PERIMETER - #3 TIES (3 TOP, R @ 12" OC) " d L " " 8 " d L " FLOWABLE FILL DOWELS TO MATCH VERT REINF SIZE AND SPACING -PROVIDE STD HOOK AT BOTTOM OF FOOTING 3" " d L " WATER STOP, TYP. REINF FOOTING W/ #7 AT 12" OC EACH WAY TOP AND BOTTOM SOIL RETAINER AND VOID CARTONS - SEE STRUCTURAL NOTES PIER - SEE PLAN 1 SECTION AT ELEVATOR PIT 3/4" = 1'-0" 2 SECTION AT ELEVATOR PIT 3/4" = 1'-0" M A 5 4 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A NO. DESCRIPTION Revisions: DATE 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES ELEVATOR PIT DETAILS S3.03 05/10/2024 MASONRY REINFORCEMENT SCHEDULE* WALL MARK WALL THICKNESS PARTIALLY OR FULLY GROUTED VERTICAL REINFORCEMENT HORIZONTAL BOND BEAM LOCATION M1 8" FULL #5 @ 8" O.C. 48" O.C. MAX & TOP OF WALL *REINFORCE PER SCHEDULE UNLESS SPECIFICALLY NOTED OTHERWISE 3 S4.00 CONTROL JOINT LINTEL SCHEDULE CLEAR SPAN 8" CMU LINTEL (f'm = 1500 PSI) 12" CMU LINTEL (f'm = 1500 PSI) STIRRUPS GROUTED JAMB CELLS 0'-0" - 4'-0" 8" DEEP W/ (2) #5 BOTTOM 8" DEEP W/ (2) #5 BOTTOM NONE 4'-0" - 6'-0" 8" DEEP W/ (2) #5 BOTTOM 8" DEEP W/ (2) #5 BOTTOM NONE 6'-0" - 8'-0" 8'-0" - 12'-0" 16" DEEP W/ (2) #5 TOP & BOTTOM 16" DEEP W/ (2) #5 TOP & BOTTOM 16" DEEP W/ (2) #5 TOP & BOTTOM 16" DEEP W/ (2) #5 TOP & BOTTOM (1) FULLY GROUTED CELL (1) FULLY GROUTED CELL (1) FULLY GROUTED CELL #3 @ 32" O.C. (3) #3 @ 9" O.C. EACH END AND REM @ 32" O.C. (2) FULLY GROUTED CELL . R L C " 2 / 1 1 R E V O C Q E Q E EXTEND HORIZONTAL REINFORCING 8" PAST FACE OF OPENING SEE CMU WALL REINFORCING DETAIL FOR HORIZONTAL JOINT REINFORCEMENT VERTICAL WALL REINFORCEMENT - SEE SCHEDULE VERTICAL WALL REINFORCEMENT TOP REINFORCEMENT - SEE SCHEDULE KNOCKOUT WEB LINTEL BLOCK STIRRUPS - SEE SCHEDULE BOTTOM REINFORCEMENT - SEE SCHEDULE PROVIDE TROUGH BLOCK AT ARCHITECTURALLY EXPOSED LINTELS . R L C " 2 / 1 R E V O C NOTES: 1. SEE TYPICAL CMU WALL ELEVATION FOR ADDITIONAL INFORMATION. 2. MASONY CONTROL JOINTS SHALL NOT BE LOCATED WITHIN LINTEL BEARING AT EACH END. 3. TEMPORARY SHORING OF LINTELS SHALL BE PROVIDED UNTIL MASONY HAS CURED. (2) #5 CONTINUOUS - TYPICAL, U.N.O. KNOCK-OUT WEB LINTEL BLOCK BOND BEAM EXTEND VERTICAL REINFORCEMENT THROUGH BOND BEAM NOTES: 1. SEE TYPICAL CMU WALL ELEVATION FOR ADDITIONAL INFORMATION. TYP 3 S4.00 4 S4.00 AT PANEL END COLUMNS AND ALL CANTILEVERED WALL BARS 2 CMU LINTEL DETAIL AND SCHEDULE 1 1/2" = 1'-0" 3 CMU BOND BEAM DETAIL 1 1/2" = 1'-0" NOTES: 1. THIS DETAIL SHALL BE USED AT ALL CMU PANEL END COLUMNS WITHIN LOAD BEARING OR SHEAR WALLS (NOT REQ'D AT PARTITION WALLS) AND AT ALL VERTICAL BARS IN CANTILEVERED CMU WALLS. 2. SEE TYPICAL CMU DOWEL DETAIL FOR DOWEL REQUIREMENTS AT ALL OTHER CONDITIONS. REINFORCEMENT. 3. SEE TYPICAL CMU WALL ELEVATION AND DETAILS FOR VERTICAL WALL 4. DOWEL SIZE AND SPACING TO MATCH VERTICAL CMU REINFORCEMENT. " E " " D " 3 1/2" MIN. DOWEL SCHEDULE BAR SIZE EMBEDMENT LENGTH D E 12" 36" 15" 45" F 7" 9" 18" 54" 10" 25" 63" 12" 30" 72" 14" 38" 82" 18" #4 #5 #6 #7 #8 #9 " E " " F " 3 1/2" MIN. CONCRETE FOUNDATION - SEE PLAN CONCRETE FOUNDATION - SEE PLAN CONCRETE FOUNDATION - SEE PLAN CONCRETE FOUNDATION - SEE PLAN CAST-IN-PLACE (STRAIGHT BAR) CAST-IN-PLACE (HOOKED BAR) CAST-IN-PLACE (STRAIGHT BAR) CAST-IN-PLACE (HOOKED BAR) 5 TYPICAL CMU DOWELS AT END COLUMNS AND CANTILEVERED WALLS 1" = 1'-0" EXTEND GROUTED JAMB CELLS TO TOP OF WALL - SEE CMU LINTEL SCHEDULE 2 S4.00 6 S4.00 2 S4.00 6 S4.00 3 S4.00 TOC = SEE PLAN 1 TYPICAL CMU WALL ELEVATION 1" = 1'-0" DOWEL SCHEDULE BAR SIZE EMBEDMENT LENGTH A B C 12" 24" 4 1/2" 15" 30" 18" 36" 25" 42" 30" 48" 6" 7" 8" 9" #4 #5 #6 #7 #8 " B " . I N M " 6 NOTES: 1. SEE TYPICAL CMU WALL ELEVATION AND DETAILS FOR VERTICAL WALL REINFORCEMENT. 2. DOWEL SIZE AND SPACING TO MATCH VERTICAL REINFORCEMENT. " B " " A " 3 1/2" MIN. 4 TYPICAL CMU DOWELS 1" = 1'-0" NOTE: SEE TYPICAL CMU WALL ELEVATION FOR ADDITIONAL INFORMATION. PROVIDE (1) #8 VERTICAL IN EACH CELL WITHIN CMU BEARING AREA, U.N.O. - SOLID GROUT ALL REINFORCED CELLS SEE CMU LINTEL SCHEDULE PLAN VIEW 6 CMU JAMB DETAIL 1 1/2" = 1'-0" M A 6 4 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A NO. DESCRIPTION Revisions: DATE 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES TYPICAL CMU DETAILS S4.00 05/10/2024 NOTES: 1. SEE TYPICAL CMU WALL ELEVATION FOR ADDITIONAL INFORMATION. 2. HORIZONTAL JOINT REINFORCEMENT SHALL CONSIST OF HOT-DIPPED GALVANIZED LADDER TYPE REINFORCEMENT WITH 9 GA. SIDE RODS AND CROSS RODS. SPACE REINFORCEMENT AT 16" O.C. U.N.O. HORIZONTAL REINFORCEMENT SHALL LAP 14" AT SPLICES AND SHALL BE DISCONTINUOUS AT CONTROL AND EXPANSION JOINTS. ADDITIONAL VERTICAL BAR MATCH VERTICAL BARS AT END VERTICAL BAR SPACING HORIZONTAL JOINT REINFORCEMENT PLAN VIEW AT END 32" (±) VERTICAL BAR SPACING 1' - 2" MINIMUM LAP (TYP.) MATCH VERTICAL BARS AT END ADDITIONAL VERTICAL BARS HORIZONTAL JOINT REINFORCEMENT NOTE: 1. SEE TYPICAL CMU WALL ELEVATION FOR ADDITIONAL INFORMATION. 2. OUTSIDE BARS EXTEND AROUND CORNER, INSIDE BARS EXTEND AS FAR AS POSSIBLE & BEND INTO CORNER CELL. #5 CORNER BAR X " 6 - ' 2 2'-6" CONTROL JOINT - SEE TYPICAL MASONRY CONTROL JOINT DETAIL BOND BEAM REINFORCEMENT BAR POSITIONER @ 48" O.C. MAX. EQ EQ VERTICAL REINFORCEMENT R E V O C R A E L C . X A M " 2 . I N M " 2 / 1 1 BAR POSITIONER @ 48" O.C. MAX. VERTICAL REINFORCEMENT ONE BAR IN CELL 8" CELL TWO BARS IN 8" CELL Q E Q E R E V O C R A E L C . X A M " 2 . I N M " 2 / 1 1 BAR POSITIONER @ 48" O.C. MAX. VERTICAL REINFORCEMENT HORIZONTAL JOINT REINFORCEMENT PLAN VIEW AT CORNER PLAN AT INTERSECTION PLAN AT CORNER " 6 - ' 2 (3) #5 CORNER BAR X 2'-6" TWO BARS IN 12" CELL 1 CMU WALL REINFORCING DETAIL 1" = 1'-0" 2 CMU BOND BEAM INTERSECTION DETAIL 1" = 1'-0" 3 CMU VERTICAL BAR PLACEMENT DETAIL 1" = 1'-0" M A 6 4 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A DOUBLE COURSE KNOCK-OUT LINTEL BLOCK BOND BEAM,TYP. (2) #4 CONTINUOUS IN EACH COURSE MASONRY VENEER - REF ARCH SEE CMU LINTEL DETAIL AND SCHEDULE 5/8" Ø HAS THREADED RODS @ 8" O.C. SET 5 1/2" INTO FULLY GROUTED CMU W/ HILTY HY 270 EPOXY -ANCHORS SHOULD BE CENTERED IN CMU CELLS CONT. L7X4X3/8 LLH (HDG) 1' - 4" ELEVATION (2) #4 CONTINUOUS IN EACH COURSE 4 STEP IN BOND BEAM DETAIL 1 1/2" = 1'-0" 5 STRUCTURAL STEEL LINTEL DETAIL 1 1/2" = 1'-0" . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A NO. DESCRIPTION Revisions: DATE 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES TYPICAL CMU DETAILS S4.01 05/10/2024 B B 1' - 6" 2" " 2 1" BASEPLATE W/ (6) 1" Ø ANCHOR BOLTS WITH 1'-6" EMBED LENGTH 2" 8" 6" 2" " 2 2" Q E Q E 2" Q E Q E 2" " 2 " 2 1/4 L L STEEL COLUMN - SEE PLAN EQ EQ STEEL COLUMN - SEE PLAN EQ EQ HSS COLUMN - SEE PLAN 6" BASE PLATE SIZE COLUMN B L T 1" ANCHOR BOLTS COLUMN ANCHOR BOLTS W12 1'-8" 1'-8" (4) 1 1/4" Ø X 1'-6" EMBED HSS6X6 1'-2" 1'-2" (4) 1" Ø X 1'-6" EMBED HSS8X8 1'-4" 1'-4" (4) 1" Ø X 1'-6" EMBED 1) WELD TO BE 1/16" SMALLER THAN THICKNESS OF TUBE 1/4 BASE PLATE "C" " 2 1/4 BASE PLATE SIZE B L T 1" 1" Q E Q E " 0 - ' 1 " 4 - ' 1 " 2 GUSSET PLATE DESIGNED BY BRACE ENGINEER BASE PLATE TYPE "A" BASE PLATE TYPE "B" 1 COLUMN BASE PLATES 1 1/2" = 1'-0" BASE PLATE - SEE SCHEDULE HIGH STRENGTH NON-SHRINK GROUT " 2 / 1 1 F1554 GR 55 ANCHOR BOLT - SEE DETAIL OR SCHEDULE FOR SIZE H T G N E L D E B M E E L U D E H C S E E S DOUBLE NUT W/ 1/2"x3"x3" WASHER PLATE TACK WELD 2 TYPICAL ANCHOR BOLT 3" = 1'-0" M A 6 4 : 0 2 : 0 1 4 2 0 2 / 8 / 5 I t v r . l a r t n e C _ R T S _ k r a P e s u o H _ D S A _ 2 2 _ 0 0 . 3 3 0 2 / 1 e s a h P - s t n e m e v o r p m I i m u d a t S k r a P e s u o H D S A I / / : s c o D k s e d o t u A . 3 7 5 1 7 8 4 3 1 7 . : f 3 8 5 1 . 7 8 4 . 3 1 7 : p 2 0 0 7 7 s a x e T , n o t s u o H , 0 0 3 1 e t i u S , m a l i M 0 0 7 . 3 5 4 6 4 2 2 0 1 2 . : f 2 3 0 6 . 4 2 2 . 0 1 2 : p 9 0 2 8 7 s a x e T , i o n o t n A n a S , 0 0 3 e t i u S , y a w d a o r B 0 4 0 4 . 1 4 4 7 8 7 4 2 1 5 . : f 6 8 2 7 . 8 7 4 . 2 1 5 : p 4 0 7 8 7 s a x e T , n i t s u A , 0 0 9 e t i u S , d a o R s g n i r p S n o t r a B 1 1 8 n i t s u A n o t s u o H i o n o t n A n a S S T N E M E V O R P M I I M U D A T S K R A P E S U O H , 1 0 7 8 7 , X T , N I T S U A , D V L B K E E R C L A O H S 1 0 3 1 K P E S H 4 3 0 0 - 1 2 . D . S . I N I T S U A NO. DESCRIPTION Revisions: DATE 05/10/2024 Project No. 2033.00 CONTRACT DOCUMENTS 4315 GUADALUPE ST AUSTIN, TX 78751 PHONE: (512) 499 0919 WWW.STRUCTURESTX.COM FIRM NO.: F-3323 STRUCTURES BASE PLATE DETAILS S5.00 05/10/2024