23.4 - 1116 W 6th St - masonry report — original pdf

Backup

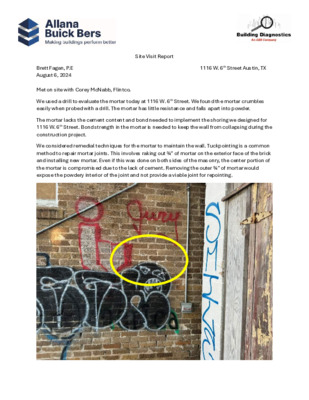

Site Visit Report Brett Fagan, P.E August 6, 2024 Met on site with Corey McNabb, Flintco. 1116 W. 6th Street Austin, TX We used a drill to evaluate the mortar today at 1116 W. 6th Street. We found the mortar crumbles easily when probed with a drill. The mortar has little resistance and falls apart into powder. The mortar lacks the cement content and bond needed to implement the shoring we designed for 1116 W. 6th Street. Bond strength in the mortar is needed to keep the wall from collapsing during the construction project. We considered remedial techniques for the mortar to maintain the wall. Tuckpointing is a common method to repair mortar joints. This involves raking out ¾” of mortar on the exterior face of the brick and installing new mortar. Even if this was done on both sides of the masonry, the center portion of the mortar is compromised due to the lack of cement. Removing the outer ¾” of mortar would expose the powdery interior of the joint and not provide a viable joint for repointing. The exterior is solid while the interior is a powder consistency. The drill easily penetrates the mortar with little resistance. There is very little material in the head joints. The material from the joint was collected as if fell out during drilling. The largest piece was removed by hand from the interior side of the wall. Most of the chunks are smaller than a nickel. The interior side of the wall shows poor installation. The head joints are open, with only a face shell of mortar on the exterior. The bed joints were not completely filled. The mortar droppings can be broken o(cid:51) by hand. For comparison we drilled holes at Swedish Hill to test the resistance of the mortar. The mortar has more consistency and was installed with better workmanship. This type of mortar is necessary to implement the shoring design we proposed for 1116.