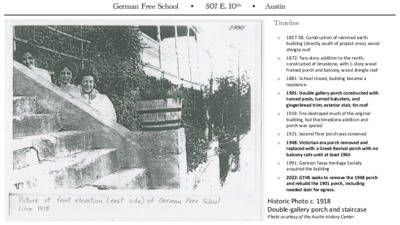

1 - 507 E 10th St - history and drawings — original pdf

Backup