B.1.1 - 2402 San Gabriel St - Drawings — original pdf

Backup

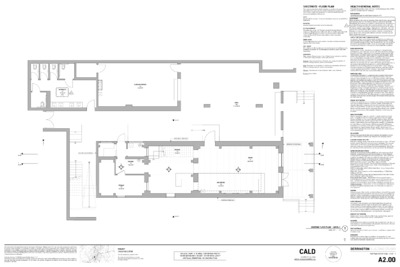

RESTROOMS 107 379.00 SF N.I.S. 06 AUXILIARY KITCHEN 106 446.50 SF PATIO 100 1,743.50 SF DN 1 0 . 3 A 1 3 A4.00 1 A4.00 DN UP EXISTING STUCCO WALL DN WH EXISTING STUCCO WALL 0 0 . 3 A 1 3 A4.00 1 A4.00 FE UP HALLWAY 104 148.50 SF 19 A5.00 17 18 20 9 A5.00 5 6 10 DINING 101 520.00 SF 3 A5.00 1 2 4 STORAGE 103 153.00 SF BAR SERVICE 102 221.00 SF EXISTING STONE WALL DN DN 3 A3.00 STORAGE 105 39.00 SF EXISTING STONE WALL 3 A3.01 SHEETNOTE • FRAMING PLAN These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the process and completion of this project. SHEETNOTE • FLOOR PLAN SHEETNOTE • EQUIPMENT PLAN These notes are intended to clarify items that are specific to the graphic These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the front of these Construction Documents for critical information about the process and completion of this project. process and completion of this project. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. KEYNOTES Keynotes located on this sheet are for this sheet only. KEYNOTES Keynotes located on this sheet are for this sheet only. 05 EXISTING ELEMENTS EXISTING ELEMENTS Floor plans and sections "cut" through vertical & horizontal elements Floor plans and sections "cut" through vertical & horizontal elements respectively. Elements such as walls, roofs, slabs, etc shall be represented with respectively. Elements such as walls, roofs, slabs, etc shall be represented with a solid fill (typically gray). In contrast, new elements will be shown with a solid fill (typically gray). In contrast, new elements will be shown with various hatches and fills that are representative of their construction various hatches and fills that are representative of their construction composition. composition. CROSS-CHECK Refer to appropriate sheet and/or schedule for additional information/detail regarding items shown herein. CROSS-CHECK Refer to appropriate sheet and/or schedule for additional information/detail regarding items shown herein. FIELD VERIFY GC to field verify all dimensions prior to construction and/or installation of any equipment, accessories, etc. If a discrepancy is identified, please notify DBS immediately. FIELD VERIFY GC to field verify all dimensions prior to construction and/or installation of any equipment, accessories, etc. If a discrepancy is identified, please notify DBS immediately. DIMENSIONS EQUIPMENT Metal framing: Dimensions are to face of frame for new construction and face Owner to provide all equipment in coffee shop. Any equipment shown in the of finish for existing conditions, unless noted otherwise. plan may not be complete or comprehensive. Coordinate with owner for complete equipment list. Concrete: Dimensions are to face of form for new construction and face of finish for existing conditions, unless noted otherwise. FURNITURE Furniture may not be represented accurately. Architect has tried to show general Steel: Dimensions are to centerline of steel for new construction and face of size and placement for clarity. Please refer to consultant drawings and finish for existing conditions, unless noted otherwise. manufacturers' installation instructions. Masonry: Dimensions are to face of masonry unless noted otherwise. Existing: Face of finish. HEALTH GENERAL NOTES This establishment shall comply with Texas Food Establishment Rules (TFER) & all City of Austin codes and ordinances. REFRIGERATION All refrigerated units are to hold foods at or below 41°F. RESTROOMS If the facility has only carry-out or seating for less than 20 people, and less than 10 employees, then only one employee restroom is required by the Health Department. Two restrooms are required if alcohol is served on the premises or more than 20 seats are provided. Each restroom must have a hand sink with forced air ventilation to the outside, covered waste receptacles for the disposal of sanitary napkins, signage stating “Employees must wash hands”, solid self closing doors and hot (at least 100°F) and cold water delivered under pressure through a mixing valve drained to the sewer to lavatories. Metered faucets must run for a min. of 15 seconds without re-activation. Restrooms may not open directly into a kitchen. SERVICE SINK, MOP SINK, CURBED FLOOR SINK At least one of these 3 types of sinks must be available for mop washing and disposal of mop water in an approved waste water disposal system. A drying rack is required for mops to air dry. This sink must be provided with a backflow preventer on any threaded hose bib to protect the water supply. Note that the mop sink may be located in a different area of the building than the kitchen. HAND WASHING SINK Shall be located to allow convenient use by employees in food preparation, food dispensing, ware wash areas, and any wait station where ice is dispensed, bar area or in a walk-in where meat is cut or trimmed. At least one hand sink will be required; additional, separate hand sinks may also be required. Small kitchens with food prep and ware washing in close proximity may be allowed to use one hand sink to serve both activities. Other hand sinks must be associated with restrooms. Provide at least 12” tall splashguards if a hand sink is located near food prep, open food, ice, or clean food contact surfaces. Otherwise, the hand sink must have at least 18” lateral separation from these. A sign or poster that notifies food employees to wash their hands shall be provided to all hand washing sinks and be clearly visible. A small, swinging door (as in a bar area) could separate a hand sink from a work area, otherwise no doors separating hand sink from work areas. Each sink must be supplied with hot (100°F) and cold water, soap and disposable towels. WARE WASH AREA A commercial dishwasher or 3 compartment sink is required. Dish machines must be able to effectively sanitize all equipment and utensils. They must dispense a chemical sanitizer or provide a final rinse of at least 180°F. (single, stationary rack machines are required to reach 165°F in the sanitize cycle). Test strips are required. Above-the-counter dish machines are required to have Type II vent-hood. Ware washing sinks shall be of sufficient size to immerse the largest piece of equipment. Cold and hot (110°F minimum) water under pressure delivered through a mixing valve shall be provided. Provide at least 2 integral drain boards or 1 integral drain board and a mobile dish cart. Drying racks or shelves will aid in adequately air drying all wares. Facilities with very limited ware washing and using disposable containers may request a variance to install a 2 compartment sink (example: convenience store). These sinks are required to have a drain board. The sinks must have an indirect connection to the sanitary sewer (at least a one inch air gap). This includes all food prep sinks and ware wash sinks. CEILING CONSTRUCTION Ceilings over open food, ice, soda fountains, ware washing, restrooms and bars must meet construction criteria and be smooth, durable, nonabsorbent, and cleanable. Open rafters, trusses or grid work and exposed duct work, pipes or utility lines are prohibited. No open structure permitted. If drop down acoustic tiles are used, they must be properly constructed. These tiles are to be washable and have a smooth surface without pinholes. Painted dry wall or boards are acceptable. WALLS AND FLOORS Must be constructed of approved materials. Cleanable water-based enamel paint is acceptable for most wall surfaces. Areas that are subject to regular cleaning and splash may be covered with FRP, stainless, or galvanized metal. Floor/wall junctures shall provide no greater than 1/32” gap. Baseboards are required. Caulk wall/floor junctures to prevent the collection of food particles and water. Masonry (brick/concrete) wall/floor junctures DO NOT require baseboards since a masonry juncture provides no gap. Raw brick and concrete in the kitchen area requires sealing. The sand grout of all tiles needs to be sealed. Epoxy grout does not require sealing. VCT floor tiles require a coat of wax to seal out liquids. SOLID WASTE Dumpster and grease barrels shall rest on a machine laid asphalt or concrete pad. These containers must have tight fitting lids and drain plugs in place. OUTDOOR COOKING FACILITIES BBQ pits or smokers shall be enclosed, and if screened in, at least a 1/16” mesh screen is required. They shall rest on a concrete or asphalt pad. The meat may only be placed on the smoker; no food prep allowed in this enclosure. Any seasoning, cutting, etc. must take place inside the establishment. Outdoor bars and wait stations will be approved on a case by case basis by the department. WATER AND SEWAGE SYSTEMS All private On-Site Sewage Facilities (OSSF) and wells serving a new Food Enterprise, an extensively remodeled Food Enterprise, or a Food Enterprise coming under new ownership must meet current standards. These systems are required to be evaluated with respect to whether the system (a) meets current standards and (b) is adequate for the proposed use. Contact the following agencies to ensure an OSSF, grease trap and/or water well is adequate: OSSF’s in the City of Austin - Austin Water Utility @ 972-0101 Grease traps in the City of Austin - City of Austin Industrial Waste @ 972-1060 OSSF’s or grease traps in Travis County - Travis County Transportation & Natural Resources @ 854-9383 OSSF’s or grease traps within 2,000 ft of Lake Travis - Lower Colorado River Authority @ 473-3216 Water wells - Texas Commission on Environmental Quality (TCEQ) Water Utilities @ 239-4691 Note: a well which serves more than 24 people per day for more than 59 days/ year is considered a public water supply. Protecting the Water Supply — Threaded hose bibs are required to have a backflow prevention device attached. Spray hoses and fill hoses shall hang at least 1 inch above the maximum flood rim of a basin or the hoses shall be provided with an atmospheric vacuum breaker or backflow prevention device. Indirect Connections — Jockey boxes, ice bins, ice machines and sinks must be provided with indirect connections to the sewer. Floor sinks are required on new construction. LIGHTING Adequate amount of light shall be provided to all areas. At least 20 foot candles is required where food is provided for customer self-service such as buffet and salad bars or where fresh produce or packaged foods are sold. At least 50 food candles is required at surfaces where employees are working with food using utensils or knives, slicers, grinders, saws, or where employee safety is a factor.\ OUTER OPENINGS All windows, vents and exterior doors shall be tight fitting. If needed, use weather stripping to provide a tight fit. All exterior doors shall have a self- closure. Screens on windows and doors shall be at least 1/16” mesh. Roll up doors to be screened or the proposed food service area provided with physical doors to create a separate walled room. Exhaust fans must be screened, or if they are louvered, must automatically close when the fan is disengaged. FOOD CONTACT SURFACES Stainless steel, Formica, polished marble, Corian, machined stone, approved ceramics or plastics may be used for food contact surfaces. COUNTERS All raw wood must be painted in areas that come in contact with food, liquid or food containers of any kind. Included is the underside of the bar above the ware wash and/or hand sink (and the splash area). TOXIC MATERIALS Specify an area where chemicals are to be stored. A well-labeled, separate shelf or cabinet is best. The architectural works depicted herein are the sole property of Derrington Building Studio, PLLC and may not be constructed or used without his express written permission. No permission to modify or reproduce any of these architectural works, including without limitation the construction of any building, is expressed or should be implied from delivery of preliminary drawings or unsealed construction drawings. Permission to construct the building depicted in sealed construction drawings is expressly conditioned on the full and timely payment of all fees otherwise due Derrington Building Studio, PLLC and, in the absence of any written agreement to the contrary, is limited to a one-time use on the site indicated on these plans. © Tuesday, February 22, 2022 Derrington Building Studio, PLLC This copyright notice and title block are “copyright management information” under the Digital Millennium Copyright Act, and are included to deter and help detect copyright infringement. For this reason, this copyright management information must be included on all copies and derivatives of this work PROJECT CAULDRON COFFEE 2402 San Gabriel Street, Austin, TX 78705 The vicinity map on the left is not to scale and intended to help generally locate the project site within the context of Austin. THIS DOCUMENT IS INTENDED FOR REVIEW AND/OR COORDINATION ONLY. DO NOT USE FOR REGULATORY APPROVAL, PERMITTING, OR CONSTRUCTION. CALD FEBRUARY 22, 2022 ARCH REVIEW COMMITTEE THIS SPACE RESERVED FOR ARCHITECT'S SEAL 02/22/2022 EXISTING FLOOR PLAN — LEVEL 1 SCALE: 1/4" = 1'-0" 1 DRAINLINES Drain lines from culinary sinks, ice machines, ice storage bins, and ware washing sinks must be provided with at least a one inch air gap, and be drained to an approved wastewater disposal system. N DERRINGTON BUILDING STUDIO EXISTING FLOOR PLAN — LEVEL 1 A2.00 SHEETNOTE • FRAMING PLAN These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the process and completion of this project. SHEETNOTE • FLOOR PLAN SHEETNOTE • EQUIPMENT PLAN These notes are intended to clarify items that are specific to the graphic These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the front of these Construction Documents for critical information about the process and completion of this project. process and completion of this project. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. KEYNOTES Keynotes located on this sheet are for this sheet only. KEYNOTES Keynotes located on this sheet are for this sheet only. 05 EXISTING ELEMENTS EXISTING ELEMENTS Floor plans and sections "cut" through vertical & horizontal elements Floor plans and sections "cut" through vertical & horizontal elements respectively. Elements such as walls, roofs, slabs, etc shall be represented with respectively. Elements such as walls, roofs, slabs, etc shall be represented with a solid fill (typically gray). In contrast, new elements will be shown with a solid fill (typically gray). In contrast, new elements will be shown with various hatches and fills that are representative of their construction various hatches and fills that are representative of their construction composition. composition. CROSS-CHECK Refer to appropriate sheet and/or schedule for additional information/detail regarding items shown herein. CROSS-CHECK Refer to appropriate sheet and/or schedule for additional information/detail regarding items shown herein. FIELD VERIFY GC to field verify all dimensions prior to construction and/or installation of any equipment, accessories, etc. If a discrepancy is identified, please notify DBS immediately. FIELD VERIFY GC to field verify all dimensions prior to construction and/or installation of any equipment, accessories, etc. If a discrepancy is identified, please notify DBS immediately. DIMENSIONS EQUIPMENT Metal framing: Dimensions are to face of frame for new construction and face Owner to provide all equipment in coffee shop. Any equipment shown in the of finish for existing conditions, unless noted otherwise. plan may not be complete or comprehensive. Coordinate with owner for complete equipment list. Concrete: Dimensions are to face of form for new construction and face of finish for existing conditions, unless noted otherwise. FURNITURE Furniture may not be represented accurately. Architect has tried to show general Steel: Dimensions are to centerline of steel for new construction and face of size and placement for clarity. Please refer to consultant drawings and finish for existing conditions, unless noted otherwise. manufacturers' installation instructions. Masonry: Dimensions are to face of masonry unless noted otherwise. Existing: Face of finish. HEALTH GENERAL NOTES This establishment shall comply with Texas Food Establishment Rules (TFER) & all City of Austin codes and ordinances. REFRIGERATION All refrigerated units are to hold foods at or below 41°F. RESTROOMS If the facility has only carry-out or seating for less than 20 people, and less than 10 employees, then only one employee restroom is required by the Health Department. Two restrooms are required if alcohol is served on the premises or more than 20 seats are provided. Each restroom must have a hand sink with forced air ventilation to the outside, covered waste receptacles for the disposal of sanitary napkins, signage stating “Employees must wash hands”, solid self closing doors and hot (at least 100°F) and cold water delivered under pressure through a mixing valve drained to the sewer to lavatories. Metered faucets must run for a min. of 15 seconds without re-activation. Restrooms may not open directly into a kitchen. SERVICE SINK, MOP SINK, CURBED FLOOR SINK At least one of these 3 types of sinks must be available for mop washing and disposal of mop water in an approved waste water disposal system. A drying rack is required for mops to air dry. This sink must be provided with a backflow preventer on any threaded hose bib to protect the water supply. Note that the mop sink may be located in a different area of the building than the kitchen. HAND WASHING SINK Shall be located to allow convenient use by employees in food preparation, food dispensing, ware wash areas, and any wait station where ice is dispensed, bar area or in a walk-in where meat is cut or trimmed. At least one hand sink will be required; additional, separate hand sinks may also be required. Small kitchens with food prep and ware washing in close proximity may be allowed to use one hand sink to serve both activities. Other hand sinks must be associated with restrooms. Provide at least 12” tall splashguards if a hand sink is located near food prep, open food, ice, or clean food contact surfaces. Otherwise, the hand sink must have at least 18” lateral separation from these. A sign or poster that notifies food employees to wash their hands shall be provided to all hand washing sinks and be clearly visible. A small, swinging door (as in a bar area) could separate a hand sink from a work area, otherwise no doors separating hand sink from work areas. Each sink must be supplied with hot (100°F) and cold water, soap and disposable towels. WARE WASH AREA A commercial dishwasher or 3 compartment sink is required. Dish machines must be able to effectively sanitize all equipment and utensils. They must dispense a chemical sanitizer or provide a final rinse of at least 180°F. (single, stationary rack machines are required to reach 165°F in the sanitize cycle). Test strips are required. Above-the-counter dish machines are required to have Type II vent-hood. Ware washing sinks shall be of sufficient size to immerse the largest piece of equipment. Cold and hot (110°F minimum) water under pressure delivered through a mixing valve shall be provided. Provide at least 2 integral drain boards or 1 integral drain board and a mobile dish cart. Drying racks or shelves will aid in adequately air drying all wares. Facilities with very limited ware washing and using disposable containers may request a variance to install a 2 compartment sink (example: convenience store). These sinks are required to have a drain board. The sinks must have an indirect connection to the sanitary sewer (at least a one inch air gap). This includes all food prep sinks and ware wash sinks. CEILING CONSTRUCTION Ceilings over open food, ice, soda fountains, ware washing, restrooms and bars must meet construction criteria and be smooth, durable, nonabsorbent, and cleanable. Open rafters, trusses or grid work and exposed duct work, pipes or utility lines are prohibited. No open structure permitted. If drop down acoustic tiles are used, they must be properly constructed. These tiles are to be washable and have a smooth surface without pinholes. Painted dry wall or boards are acceptable. WALLS AND FLOORS Must be constructed of approved materials. Cleanable water-based enamel paint is acceptable for most wall surfaces. Areas that are subject to regular cleaning and splash may be covered with FRP, stainless, or galvanized metal. Floor/wall junctures shall provide no greater than 1/32” gap. Baseboards are required. Caulk wall/floor junctures to prevent the collection of food particles and water. Masonry (brick/concrete) wall/floor junctures DO NOT require baseboards since a masonry juncture provides no gap. Raw brick and concrete in the kitchen area requires sealing. The sand grout of all tiles needs to be sealed. Epoxy grout does not require sealing. VCT floor tiles require a coat of wax to seal out liquids. SOLID WASTE Dumpster and grease barrels shall rest on a machine laid asphalt or concrete pad. These containers must have tight fitting lids and drain plugs in place. OUTDOOR COOKING FACILITIES BBQ pits or smokers shall be enclosed, and if screened in, at least a 1/16” mesh screen is required. They shall rest on a concrete or asphalt pad. The meat may only be placed on the smoker; no food prep allowed in this enclosure. Any seasoning, cutting, etc. must take place inside the establishment. Outdoor bars and wait stations will be approved on a case by case basis by the department. WATER AND SEWAGE SYSTEMS All private On-Site Sewage Facilities (OSSF) and wells serving a new Food Enterprise, an extensively remodeled Food Enterprise, or a Food Enterprise coming under new ownership must meet current standards. These systems are required to be evaluated with respect to whether the system (a) meets current standards and (b) is adequate for the proposed use. Contact the following agencies to ensure an OSSF, grease trap and/or water well is adequate: OSSF’s in the City of Austin - Austin Water Utility @ 972-0101 Grease traps in the City of Austin - City of Austin Industrial Waste @ 972-1060 OSSF’s or grease traps in Travis County - Travis County Transportation & Natural Resources @ 854-9383 OSSF’s or grease traps within 2,000 ft of Lake Travis - Lower Colorado River Authority @ 473-3216 Water wells - Texas Commission on Environmental Quality (TCEQ) Water Utilities @ 239-4691 Note: a well which serves more than 24 people per day for more than 59 days/ year is considered a public water supply. Protecting the Water Supply — Threaded hose bibs are required to have a backflow prevention device attached. Spray hoses and fill hoses shall hang at least 1 inch above the maximum flood rim of a basin or the hoses shall be provided with an atmospheric vacuum breaker or backflow prevention device. Indirect Connections — Jockey boxes, ice bins, ice machines and sinks must be provided with indirect connections to the sewer. Floor sinks are required on new construction. LIGHTING Adequate amount of light shall be provided to all areas. At least 20 foot candles is required where food is provided for customer self-service such as buffet and salad bars or where fresh produce or packaged foods are sold. At least 50 food candles is required at surfaces where employees are working with food using utensils or knives, slicers, grinders, saws, or where employee safety is a factor.\ OUTER OPENINGS All windows, vents and exterior doors shall be tight fitting. If needed, use weather stripping to provide a tight fit. All exterior doors shall have a self- closure. Screens on windows and doors shall be at least 1/16” mesh. Roll up doors to be screened or the proposed food service area provided with physical doors to create a separate walled room. Exhaust fans must be screened, or if they are louvered, must automatically close when the fan is disengaged. FOOD CONTACT SURFACES Stainless steel, Formica, polished marble, Corian, machined stone, approved ceramics or plastics may be used for food contact surfaces. COUNTERS All raw wood must be painted in areas that come in contact with food, liquid or food containers of any kind. Included is the underside of the bar above the ware wash and/or hand sink (and the splash area). TOXIC MATERIALS Specify an area where chemicals are to be stored. A well-labeled, separate shelf or cabinet is best. 1 0 . 3 A 1 EXISTING STONE WALL EXISTING WOOD PANELING 04 STORAGE 202 295.75 SF 15 A5.01 13 14 16 DN EXISTING STUCCO WALL DN STORAGE 203 33.00 SF FE DN LOUNGE 201 937.75 SF 3 A5.01 1 2 4 0 0 . 3 A 1 3 A4.00 1 A4.00 EXISTING WOOD PANELING EXISTING STONE WALL EXISTING WOOD FLOORING EXISTING STONE WALL EXISTING WOOD PANELING 3 A3.00 3 A3.01 The architectural works depicted herein are the sole property of Derrington Building Studio, PLLC and may not be constructed or used without his express written permission. No permission to modify or reproduce any of these architectural works, including without limitation the construction of any building, is expressed or should be implied from delivery of preliminary drawings or unsealed construction drawings. Permission to construct the building depicted in sealed construction drawings is expressly conditioned on the full and timely payment of all fees otherwise due Derrington Building Studio, PLLC and, in the absence of any written agreement to the contrary, is limited to a one-time use on the site indicated on these plans. © Tuesday, February 22, 2022 Derrington Building Studio, PLLC This copyright notice and title block are “copyright management information” under the Digital Millennium Copyright Act, and are included to deter and help detect copyright infringement. For this reason, this copyright management information must be included on all copies and derivatives of this work PROJECT CAULDRON COFFEE 2402 San Gabriel Street, Austin, TX 78705 The vicinity map on the left is not to scale and intended to help generally locate the project site within the context of Austin. THIS DOCUMENT IS INTENDED FOR REVIEW AND/OR COORDINATION ONLY. DO NOT USE FOR REGULATORY APPROVAL, PERMITTING, OR CONSTRUCTION. CALD FEBRUARY 22, 2022 ARCH REVIEW COMMITTEE THIS SPACE RESERVED FOR ARCHITECT'S SEAL 02/22/2022 EXISTING FLOOR PLAN — LEVEL 2 SCALE: 1/4" = 1'-0" 1 DRAINLINES Drain lines from culinary sinks, ice machines, ice storage bins, and ware washing sinks must be provided with at least a one inch air gap, and be drained to an approved wastewater disposal system. N DERRINGTON BUILDING STUDIO EXISTING FLOOR PLAN — LEVEL 2 A2.01 RESTROOMS 107 379.00 SF N.I.S. 06 AUXILIARY KITCHEN 106 446.50 SF PATIO 100 1,743.50 SF DN 1 0 . 3 A 1 3 A4.00 1 A4.00 DN UP EXISTING STUCCO WALL DN WH EXISTING STUCCO WALL 0 0 . 3 A 1 3 A4.00 1 A4.00 FE UP HALLWAY 104 148.50 SF 19 A5.00 17 18 20 9 A5.00 5 6 10 DINING 101 520.00 SF 3 A5.00 1 2 4 STORAGE 103 153.00 SF BAR SERVICE 102 221.00 SF EXISTING STONE WALL DN DN 3 A3.00 STORAGE 105 39.00 SF EXISTING STONE WALL 3 A3.01 SHEETNOTE • FRAMING PLAN These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the process and completion of this project. SHEETNOTE • FLOOR PLAN SHEETNOTE • EQUIPMENT PLAN These notes are intended to clarify items that are specific to the graphic These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the front of these Construction Documents for critical information about the process and completion of this project. process and completion of this project. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. KEYNOTES Keynotes located on this sheet are for this sheet only. KEYNOTES Keynotes located on this sheet are for this sheet only. 05 EXISTING ELEMENTS EXISTING ELEMENTS Floor plans and sections "cut" through vertical & horizontal elements Floor plans and sections "cut" through vertical & horizontal elements respectively. Elements such as walls, roofs, slabs, etc shall be represented with respectively. Elements such as walls, roofs, slabs, etc shall be represented with a solid fill (typically gray). In contrast, new elements will be shown with a solid fill (typically gray). In contrast, new elements will be shown with various hatches and fills that are representative of their construction various hatches and fills that are representative of their construction composition. composition. CROSS-CHECK Refer to appropriate sheet and/or schedule for additional information/detail regarding items shown herein. CROSS-CHECK Refer to appropriate sheet and/or schedule for additional information/detail regarding items shown herein. FIELD VERIFY GC to field verify all dimensions prior to construction and/or installation of any equipment, accessories, etc. If a discrepancy is identified, please notify DBS immediately. FIELD VERIFY GC to field verify all dimensions prior to construction and/or installation of any equipment, accessories, etc. If a discrepancy is identified, please notify DBS immediately. DIMENSIONS EQUIPMENT Metal framing: Dimensions are to face of frame for new construction and face Owner to provide all equipment in coffee shop. Any equipment shown in the of finish for existing conditions, unless noted otherwise. plan may not be complete or comprehensive. Coordinate with owner for complete equipment list. Concrete: Dimensions are to face of form for new construction and face of finish for existing conditions, unless noted otherwise. FURNITURE Furniture may not be represented accurately. Architect has tried to show general Steel: Dimensions are to centerline of steel for new construction and face of size and placement for clarity. Please refer to consultant drawings and finish for existing conditions, unless noted otherwise. manufacturers' installation instructions. Masonry: Dimensions are to face of masonry unless noted otherwise. Existing: Face of finish. HEALTH GENERAL NOTES This establishment shall comply with Texas Food Establishment Rules (TFER) & all City of Austin codes and ordinances. REFRIGERATION All refrigerated units are to hold foods at or below 41°F. RESTROOMS If the facility has only carry-out or seating for less than 20 people, and less than 10 employees, then only one employee restroom is required by the Health Department. Two restrooms are required if alcohol is served on the premises or more than 20 seats are provided. Each restroom must have a hand sink with forced air ventilation to the outside, covered waste receptacles for the disposal of sanitary napkins, signage stating “Employees must wash hands”, solid self closing doors and hot (at least 100°F) and cold water delivered under pressure through a mixing valve drained to the sewer to lavatories. Metered faucets must run for a min. of 15 seconds without re-activation. Restrooms may not open directly into a kitchen. SERVICE SINK, MOP SINK, CURBED FLOOR SINK At least one of these 3 types of sinks must be available for mop washing and disposal of mop water in an approved waste water disposal system. A drying rack is required for mops to air dry. This sink must be provided with a backflow preventer on any threaded hose bib to protect the water supply. Note that the mop sink may be located in a different area of the building than the kitchen. HAND WASHING SINK Shall be located to allow convenient use by employees in food preparation, food dispensing, ware wash areas, and any wait station where ice is dispensed, bar area or in a walk-in where meat is cut or trimmed. At least one hand sink will be required; additional, separate hand sinks may also be required. Small kitchens with food prep and ware washing in close proximity may be allowed to use one hand sink to serve both activities. Other hand sinks must be associated with restrooms. Provide at least 12” tall splashguards if a hand sink is located near food prep, open food, ice, or clean food contact surfaces. Otherwise, the hand sink must have at least 18” lateral separation from these. A sign or poster that notifies food employees to wash their hands shall be provided to all hand washing sinks and be clearly visible. A small, swinging door (as in a bar area) could separate a hand sink from a work area, otherwise no doors separating hand sink from work areas. Each sink must be supplied with hot (100°F) and cold water, soap and disposable towels. WARE WASH AREA A commercial dishwasher or 3 compartment sink is required. Dish machines must be able to effectively sanitize all equipment and utensils. They must dispense a chemical sanitizer or provide a final rinse of at least 180°F. (single, stationary rack machines are required to reach 165°F in the sanitize cycle). Test strips are required. Above-the-counter dish machines are required to have Type II vent-hood. Ware washing sinks shall be of sufficient size to immerse the largest piece of equipment. Cold and hot (110°F minimum) water under pressure delivered through a mixing valve shall be provided. Provide at least 2 integral drain boards or 1 integral drain board and a mobile dish cart. Drying racks or shelves will aid in adequately air drying all wares. Facilities with very limited ware washing and using disposable containers may request a variance to install a 2 compartment sink (example: convenience store). These sinks are required to have a drain board. The sinks must have an indirect connection to the sanitary sewer (at least a one inch air gap). This includes all food prep sinks and ware wash sinks. CEILING CONSTRUCTION Ceilings over open food, ice, soda fountains, ware washing, restrooms and bars must meet construction criteria and be smooth, durable, nonabsorbent, and cleanable. Open rafters, trusses or grid work and exposed duct work, pipes or utility lines are prohibited. No open structure permitted. If drop down acoustic tiles are used, they must be properly constructed. These tiles are to be washable and have a smooth surface without pinholes. Painted dry wall or boards are acceptable. WALLS AND FLOORS Must be constructed of approved materials. Cleanable water-based enamel paint is acceptable for most wall surfaces. Areas that are subject to regular cleaning and splash may be covered with FRP, stainless, or galvanized metal. Floor/wall junctures shall provide no greater than 1/32” gap. Baseboards are required. Caulk wall/floor junctures to prevent the collection of food particles and water. Masonry (brick/concrete) wall/floor junctures DO NOT require baseboards since a masonry juncture provides no gap. Raw brick and concrete in the kitchen area requires sealing. The sand grout of all tiles needs to be sealed. Epoxy grout does not require sealing. VCT floor tiles require a coat of wax to seal out liquids. SOLID WASTE Dumpster and grease barrels shall rest on a machine laid asphalt or concrete pad. These containers must have tight fitting lids and drain plugs in place. OUTDOOR COOKING FACILITIES BBQ pits or smokers shall be enclosed, and if screened in, at least a 1/16” mesh screen is required. They shall rest on a concrete or asphalt pad. The meat may only be placed on the smoker; no food prep allowed in this enclosure. Any seasoning, cutting, etc. must take place inside the establishment. Outdoor bars and wait stations will be approved on a case by case basis by the department. WATER AND SEWAGE SYSTEMS All private On-Site Sewage Facilities (OSSF) and wells serving a new Food Enterprise, an extensively remodeled Food Enterprise, or a Food Enterprise coming under new ownership must meet current standards. These systems are required to be evaluated with respect to whether the system (a) meets current standards and (b) is adequate for the proposed use. Contact the following agencies to ensure an OSSF, grease trap and/or water well is adequate: OSSF’s in the City of Austin - Austin Water Utility @ 972-0101 Grease traps in the City of Austin - City of Austin Industrial Waste @ 972-1060 OSSF’s or grease traps in Travis County - Travis County Transportation & Natural Resources @ 854-9383 OSSF’s or grease traps within 2,000 ft of Lake Travis - Lower Colorado River Authority @ 473-3216 Water wells - Texas Commission on Environmental Quality (TCEQ) Water Utilities @ 239-4691 Note: a well which serves more than 24 people per day for more than 59 days/ year is considered a public water supply. Protecting the Water Supply — Threaded hose bibs are required to have a backflow prevention device attached. Spray hoses and fill hoses shall hang at least 1 inch above the maximum flood rim of a basin or the hoses shall be provided with an atmospheric vacuum breaker or backflow prevention device. Indirect Connections — Jockey boxes, ice bins, ice machines and sinks must be provided with indirect connections to the sewer. Floor sinks are required on new construction. LIGHTING Adequate amount of light shall be provided to all areas. At least 20 foot candles is required where food is provided for customer self-service such as buffet and salad bars or where fresh produce or packaged foods are sold. At least 50 food candles is required at surfaces where employees are working with food using utensils or knives, slicers, grinders, saws, or where employee safety is a factor.\ OUTER OPENINGS All windows, vents and exterior doors shall be tight fitting. If needed, use weather stripping to provide a tight fit. All exterior doors shall have a self- closure. Screens on windows and doors shall be at least 1/16” mesh. Roll up doors to be screened or the proposed food service area provided with physical doors to create a separate walled room. Exhaust fans must be screened, or if they are louvered, must automatically close when the fan is disengaged. FOOD CONTACT SURFACES Stainless steel, Formica, polished marble, Corian, machined stone, approved ceramics or plastics may be used for food contact surfaces. COUNTERS All raw wood must be painted in areas that come in contact with food, liquid or food containers of any kind. Included is the underside of the bar above the ware wash and/or hand sink (and the splash area). TOXIC MATERIALS Specify an area where chemicals are to be stored. A well-labeled, separate shelf or cabinet is best. The architectural works depicted herein are the sole property of Derrington Building Studio, PLLC and may not be constructed or used without his express written permission. No permission to modify or reproduce any of these architectural works, including without limitation the construction of any building, is expressed or should be implied from delivery of preliminary drawings or unsealed construction drawings. Permission to construct the building depicted in sealed construction drawings is expressly conditioned on the full and timely payment of all fees otherwise due Derrington Building Studio, PLLC and, in the absence of any written agreement to the contrary, is limited to a one-time use on the site indicated on these plans. © Tuesday, February 22, 2022 Derrington Building Studio, PLLC This copyright notice and title block are “copyright management information” under the Digital Millennium Copyright Act, and are included to deter and help detect copyright infringement. For this reason, this copyright management information must be included on all copies and derivatives of this work PROJECT CAULDRON COFFEE 2402 San Gabriel Street, Austin, TX 78705 The vicinity map on the left is not to scale and intended to help generally locate the project site within the context of Austin. THIS DOCUMENT IS INTENDED FOR REVIEW AND/OR COORDINATION ONLY. DO NOT USE FOR REGULATORY APPROVAL, PERMITTING, OR CONSTRUCTION. CALD FEBRUARY 22, 2022 ARCH REVIEW COMMITTEE THIS SPACE RESERVED FOR ARCHITECT'S SEAL 02/22/2022 PROPOSED FLOOR PLAN — LEVEL 1 SCALE: 1/4" = 1'-0" 1 DRAINLINES Drain lines from culinary sinks, ice machines, ice storage bins, and ware washing sinks must be provided with at least a one inch air gap, and be drained to an approved wastewater disposal system. N DERRINGTON BUILDING STUDIO PROPOSED FLOOR PLAN — LEVEL 1 A2.02 SHEETNOTE • FRAMING PLAN These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the process and completion of this project. SHEETNOTE • FLOOR PLAN SHEETNOTE • EQUIPMENT PLAN These notes are intended to clarify items that are specific to the graphic These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the front of these Construction Documents for critical information about the process and completion of this project. process and completion of this project. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. KEYNOTES Keynotes located on this sheet are for this sheet only. KEYNOTES Keynotes located on this sheet are for this sheet only. 05 EXISTING ELEMENTS EXISTING ELEMENTS Floor plans and sections "cut" through vertical & horizontal elements Floor plans and sections "cut" through vertical & horizontal elements respectively. Elements such as walls, roofs, slabs, etc shall be represented with respectively. Elements such as walls, roofs, slabs, etc shall be represented with a solid fill (typically gray). In contrast, new elements will be shown with a solid fill (typically gray). In contrast, new elements will be shown with various hatches and fills that are representative of their construction various hatches and fills that are representative of their construction composition. composition. CROSS-CHECK Refer to appropriate sheet and/or schedule for additional information/detail regarding items shown herein. CROSS-CHECK Refer to appropriate sheet and/or schedule for additional information/detail regarding items shown herein. FIELD VERIFY GC to field verify all dimensions prior to construction and/or installation of any equipment, accessories, etc. If a discrepancy is identified, please notify DBS immediately. FIELD VERIFY GC to field verify all dimensions prior to construction and/or installation of any equipment, accessories, etc. If a discrepancy is identified, please notify DBS immediately. DIMENSIONS EQUIPMENT Metal framing: Dimensions are to face of frame for new construction and face Owner to provide all equipment in coffee shop. Any equipment shown in the of finish for existing conditions, unless noted otherwise. plan may not be complete or comprehensive. Coordinate with owner for complete equipment list. Concrete: Dimensions are to face of form for new construction and face of finish for existing conditions, unless noted otherwise. FURNITURE Furniture may not be represented accurately. Architect has tried to show general Steel: Dimensions are to centerline of steel for new construction and face of size and placement for clarity. Please refer to consultant drawings and finish for existing conditions, unless noted otherwise. manufacturers' installation instructions. Masonry: Dimensions are to face of masonry unless noted otherwise. Existing: Face of finish. HEALTH GENERAL NOTES This establishment shall comply with Texas Food Establishment Rules (TFER) & all City of Austin codes and ordinances. REFRIGERATION All refrigerated units are to hold foods at or below 41°F. RESTROOMS If the facility has only carry-out or seating for less than 20 people, and less than 10 employees, then only one employee restroom is required by the Health Department. Two restrooms are required if alcohol is served on the premises or more than 20 seats are provided. Each restroom must have a hand sink with forced air ventilation to the outside, covered waste receptacles for the disposal of sanitary napkins, signage stating “Employees must wash hands”, solid self closing doors and hot (at least 100°F) and cold water delivered under pressure through a mixing valve drained to the sewer to lavatories. Metered faucets must run for a min. of 15 seconds without re-activation. Restrooms may not open directly into a kitchen. SERVICE SINK, MOP SINK, CURBED FLOOR SINK At least one of these 3 types of sinks must be available for mop washing and disposal of mop water in an approved waste water disposal system. A drying rack is required for mops to air dry. This sink must be provided with a backflow preventer on any threaded hose bib to protect the water supply. Note that the mop sink may be located in a different area of the building than the kitchen. HAND WASHING SINK Shall be located to allow convenient use by employees in food preparation, food dispensing, ware wash areas, and any wait station where ice is dispensed, bar area or in a walk-in where meat is cut or trimmed. At least one hand sink will be required; additional, separate hand sinks may also be required. Small kitchens with food prep and ware washing in close proximity may be allowed to use one hand sink to serve both activities. Other hand sinks must be associated with restrooms. Provide at least 12” tall splashguards if a hand sink is located near food prep, open food, ice, or clean food contact surfaces. Otherwise, the hand sink must have at least 18” lateral separation from these. A sign or poster that notifies food employees to wash their hands shall be provided to all hand washing sinks and be clearly visible. A small, swinging door (as in a bar area) could separate a hand sink from a work area, otherwise no doors separating hand sink from work areas. Each sink must be supplied with hot (100°F) and cold water, soap and disposable towels. WARE WASH AREA A commercial dishwasher or 3 compartment sink is required. Dish machines must be able to effectively sanitize all equipment and utensils. They must dispense a chemical sanitizer or provide a final rinse of at least 180°F. (single, stationary rack machines are required to reach 165°F in the sanitize cycle). Test strips are required. Above-the-counter dish machines are required to have Type II vent-hood. Ware washing sinks shall be of sufficient size to immerse the largest piece of equipment. Cold and hot (110°F minimum) water under pressure delivered through a mixing valve shall be provided. Provide at least 2 integral drain boards or 1 integral drain board and a mobile dish cart. Drying racks or shelves will aid in adequately air drying all wares. Facilities with very limited ware washing and using disposable containers may request a variance to install a 2 compartment sink (example: convenience store). These sinks are required to have a drain board. The sinks must have an indirect connection to the sanitary sewer (at least a one inch air gap). This includes all food prep sinks and ware wash sinks. CEILING CONSTRUCTION Ceilings over open food, ice, soda fountains, ware washing, restrooms and bars must meet construction criteria and be smooth, durable, nonabsorbent, and cleanable. Open rafters, trusses or grid work and exposed duct work, pipes or utility lines are prohibited. No open structure permitted. If drop down acoustic tiles are used, they must be properly constructed. These tiles are to be washable and have a smooth surface without pinholes. Painted dry wall or boards are acceptable. WALLS AND FLOORS Must be constructed of approved materials. Cleanable water-based enamel paint is acceptable for most wall surfaces. Areas that are subject to regular cleaning and splash may be covered with FRP, stainless, or galvanized metal. Floor/wall junctures shall provide no greater than 1/32” gap. Baseboards are required. Caulk wall/floor junctures to prevent the collection of food particles and water. Masonry (brick/concrete) wall/floor junctures DO NOT require baseboards since a masonry juncture provides no gap. Raw brick and concrete in the kitchen area requires sealing. The sand grout of all tiles needs to be sealed. Epoxy grout does not require sealing. VCT floor tiles require a coat of wax to seal out liquids. SOLID WASTE Dumpster and grease barrels shall rest on a machine laid asphalt or concrete pad. These containers must have tight fitting lids and drain plugs in place. OUTDOOR COOKING FACILITIES BBQ pits or smokers shall be enclosed, and if screened in, at least a 1/16” mesh screen is required. They shall rest on a concrete or asphalt pad. The meat may only be placed on the smoker; no food prep allowed in this enclosure. Any seasoning, cutting, etc. must take place inside the establishment. Outdoor bars and wait stations will be approved on a case by case basis by the department. WATER AND SEWAGE SYSTEMS All private On-Site Sewage Facilities (OSSF) and wells serving a new Food Enterprise, an extensively remodeled Food Enterprise, or a Food Enterprise coming under new ownership must meet current standards. These systems are required to be evaluated with respect to whether the system (a) meets current standards and (b) is adequate for the proposed use. Contact the following agencies to ensure an OSSF, grease trap and/or water well is adequate: OSSF’s in the City of Austin - Austin Water Utility @ 972-0101 Grease traps in the City of Austin - City of Austin Industrial Waste @ 972-1060 OSSF’s or grease traps in Travis County - Travis County Transportation & Natural Resources @ 854-9383 OSSF’s or grease traps within 2,000 ft of Lake Travis - Lower Colorado River Authority @ 473-3216 Water wells - Texas Commission on Environmental Quality (TCEQ) Water Utilities @ 239-4691 Note: a well which serves more than 24 people per day for more than 59 days/ year is considered a public water supply. Protecting the Water Supply — Threaded hose bibs are required to have a backflow prevention device attached. Spray hoses and fill hoses shall hang at least 1 inch above the maximum flood rim of a basin or the hoses shall be provided with an atmospheric vacuum breaker or backflow prevention device. Indirect Connections — Jockey boxes, ice bins, ice machines and sinks must be provided with indirect connections to the sewer. Floor sinks are required on new construction. LIGHTING Adequate amount of light shall be provided to all areas. At least 20 foot candles is required where food is provided for customer self-service such as buffet and salad bars or where fresh produce or packaged foods are sold. At least 50 food candles is required at surfaces where employees are working with food using utensils or knives, slicers, grinders, saws, or where employee safety is a factor.\ OUTER OPENINGS All windows, vents and exterior doors shall be tight fitting. If needed, use weather stripping to provide a tight fit. All exterior doors shall have a self- closure. Screens on windows and doors shall be at least 1/16” mesh. Roll up doors to be screened or the proposed food service area provided with physical doors to create a separate walled room. Exhaust fans must be screened, or if they are louvered, must automatically close when the fan is disengaged. FOOD CONTACT SURFACES Stainless steel, Formica, polished marble, Corian, machined stone, approved ceramics or plastics may be used for food contact surfaces. COUNTERS All raw wood must be painted in areas that come in contact with food, liquid or food containers of any kind. Included is the underside of the bar above the ware wash and/or hand sink (and the splash area). TOXIC MATERIALS Specify an area where chemicals are to be stored. A well-labeled, separate shelf or cabinet is best. 1 0 . 3 A 1 EXISTING STONE WALL NEW WOODEN RAILING 04 STORAGE 202 295.75 SF 15 A5.01 13 14 16 DN EXISTING STUCCO WALL DN STORAGE 203 33.00 SF FE DN 03 LOUNGE 201 937.75 SF 3 A5.01 1 2 4 0 0 . 3 A 1 3 A4.00 1 A4.00 EXISTING COLUMN EXISTING STONE WALL EXISTING COLUMN EXISTING WOOD FLOORING EXISTING STONE WALL EXISTING COLUMN 3 A3.00 3 A3.01 The architectural works depicted herein are the sole property of Derrington Building Studio, PLLC and may not be constructed or used without his express written permission. No permission to modify or reproduce any of these architectural works, including without limitation the construction of any building, is expressed or should be implied from delivery of preliminary drawings or unsealed construction drawings. Permission to construct the building depicted in sealed construction drawings is expressly conditioned on the full and timely payment of all fees otherwise due Derrington Building Studio, PLLC and, in the absence of any written agreement to the contrary, is limited to a one-time use on the site indicated on these plans. © Tuesday, February 22, 2022 Derrington Building Studio, PLLC This copyright notice and title block are “copyright management information” under the Digital Millennium Copyright Act, and are included to deter and help detect copyright infringement. For this reason, this copyright management information must be included on all copies and derivatives of this work PROJECT CAULDRON COFFEE 2402 San Gabriel Street, Austin, TX 78705 The vicinity map on the left is not to scale and intended to help generally locate the project site within the context of Austin. THIS DOCUMENT IS INTENDED FOR REVIEW AND/OR COORDINATION ONLY. DO NOT USE FOR REGULATORY APPROVAL, PERMITTING, OR CONSTRUCTION. CALD FEBRUARY 22, 2022 ARCH REVIEW COMMITTEE THIS SPACE RESERVED FOR ARCHITECT'S SEAL 02/22/2022 PROPOSED FLOOR PLAN — LEVEL 2 SCALE: 1/4" = 1'-0" 1 DRAINLINES Drain lines from culinary sinks, ice machines, ice storage bins, and ware washing sinks must be provided with at least a one inch air gap, and be drained to an approved wastewater disposal system. N DERRINGTON BUILDING STUDIO PROPOSED FLOOR PLAN — LEVEL 2 A2.03 EXISTING ROOF EXISTING WOOD COLUMN EXISTING WOOD BEAM EXISTING RAILING EXISTING CONCRETE PORCH STEPS EXISTING WOOD PANELING EXISTING STUCCO WALL EXISTING STUCCO COLUMN EXISTING METAL COLUMN EXISTING RAILING EXISTING STONE EXISTING WOOD PANELING EXISTING STUCCO +22'-6" Roof (Bottom of Slab) +12'-6" Level Two (Top of Slab) ±0" Level One (Top of Slab) EXISTING NORTH ELEVATION (RIGHT SIDE OF LOT) SCALE: 1/4" = 1'-0" 3 EXISTING STONE EXISTING WOOD PANELING EXISTING WOODEN SCREENED WINDOWS EXISTING ROOF EXISTING STUCCO WALL EXISTING RAILING +22'-6" Roof (Bottom of Slab) SHEETNOTE • RCP These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the process and completion of this project. SHEETNOTE • EXTERIOR ELEVATION These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the process and completion of this project. SCHEDULES Reference schedules (MEP and/or architectural) for fixture types and specifications. ELEVATION HEIGHTS Any ceiling elevations indicated are above local finished floor level. +12'-6" Level Two (Top of Slab) FIRE ALAMRS Fire alarms are shown in elevations for location only. Refer to MEP for specifications and manufacturers instructions. LIGHT FIXTURES Light fixtures are shown in elevations for location only. refer to electrical drawings and specifications. INTERIOR COORDINATION Coordinate final light fixture height and location with interior designer. CROSS REFERENCE Some elevations contain angled planes and should not be scaled - refer to plans. DIMENSIONS All RCP dimensions are from finish to finish or to center line of fixture, unless noted otherwise. COURSING All window installations to course with existing brick. KEYNOTES Keynotes located on this sheet are for this sheet only. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. FIELD VERIFY GC to field verify all dimensions prior to construction and/or installation of any equipment, accessories, etc. If a discrepancy is identified, please notify DBS immediately. INTENTION Any demolition drawings and notes are provided for convenience and information only and are not intended to represent the comprehensive state of the building(s). Verify the existing state of the building(s) finishes and building systems. ±0" Level One (Top of Slab) INVESTIGATION The contractor shall make a thorough investigation of conditions where demolition is required and shall familiarize himself with the scope of demolition work required. EXISTING EAST ELEVATION (FRONT OF LOT) SCALE: 1/4" = 1'-0" 1 CALD FEBRUARY 22, 2022 ARCH REVIEW COMMITTEE THIS SPACE RESERVED FOR ARCHITECT'S SEAL 02/22/2022 UNFORESEEN CONDITIONS If conditions or questions arise regarding the intent of construction documents, Contractor to contact architect immediately prior to proceeding with work in question. When, during the course of demolition activities, conditions are encountered (i.e., underground utilities; structural components) which could not have been foreseen or not specifically indicated on the drawings, shore and brace to a safe condition or support as required, cease activity and immediately notify the architect for direction. DERRINGTON BUILDING STUDIO BUILDING ELEVATION — EXISTING A3.00 The architectural works depicted herein are the sole property of Derrington Building Studio, PLLC and may not be constructed or used without his express written permission. No permission to modify or reproduce any of these architectural works, including without limitation the construction of any building, is expressed or should be implied from delivery of preliminary drawings or unsealed construction drawings. Permission to construct the building depicted in sealed construction drawings is expressly conditioned on the full and timely payment of all fees otherwise due Derrington Building Studio, PLLC and, in the absence of any written agreement to the contrary, is limited to a one-time use on the site indicated on these plans. © Tuesday, February 22, 2022 Derrington Building Studio, PLLC This copyright notice and title block are “copyright management information” under the Digital Millennium Copyright Act, and are included to deter and help detect copyright infringement. For this reason, this copyright management information must be included on all copies and derivatives of this work PROJECT CAULDRON COFFEE 2402 San Gabriel Street, Austin, TX 78705 The vicinity map on the left is not to scale and intended to help generally locate the project site within the context of Austin. THIS DOCUMENT IS INTENDED FOR REVIEW AND/OR COORDINATION ONLY. DO NOT USE FOR REGULATORY APPROVAL, PERMITTING, OR CONSTRUCTION. EXISTING WOOD PANEL EXISTING STONE EXISTING STUCCO EXISTING ROOF EXISTING WOOD COLUMN EXISTING WOODEN SCREENED WINDOWS +22'-6" Roof (Bottom of Slab) +12'-6" Level Two (Top of Slab) EXISTING WOOD PANELING EXISTING BEAM EXISTING METAL COLUMN EXISTING STUCCO COLUMN EXISTING RAILING EXISTING RAILING ±0" Level One (Top of Slab) EXISTING CONCRETE STEPS EXISTING SOUTH ELEVATION (LEFT SIDE OF LOT) SCALE: 1/4" = 1'-0" 3 EXISTING STONE +22'-6" Roof (Bottom of Slab) EXISTING STUCCO WALL KEYNOTES Keynotes located on this sheet are for this sheet only. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. SHEETNOTE • RCP These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the process and completion of this project. SHEETNOTE • EXTERIOR ELEVATION These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the process and completion of this project. SCHEDULES Reference schedules (MEP and/or architectural) for fixture types and specifications. ELEVATION HEIGHTS Any ceiling elevations indicated are above local finished floor level. +12'-6" Level Two (Top of Slab) FIRE ALAMRS Fire alarms are shown in elevations for location only. Refer to MEP for specifications and manufacturers instructions. LIGHT FIXTURES Light fixtures are shown in elevations for location only. refer to electrical drawings and specifications. INTERIOR COORDINATION Coordinate final light fixture height and location with interior designer. CROSS REFERENCE Some elevations contain angled planes and should not be scaled - refer to plans. DIMENSIONS All RCP dimensions are from finish to finish or to center line of fixture, unless noted otherwise. COURSING All window installations to course with existing brick. FIELD VERIFY GC to field verify all dimensions prior to construction and/or installation of any equipment, accessories, etc. If a discrepancy is identified, please notify DBS immediately. INTENTION Any demolition drawings and notes are provided for convenience and information only and are not intended to represent the comprehensive state of the building(s). Verify the existing state of the building(s) finishes and building systems. ±0" Level One (Top of Slab) INVESTIGATION The contractor shall make a thorough investigation of conditions where demolition is required and shall familiarize himself with the scope of demolition work required. EXISTING WEST ELEVATION (REAR OF LOT) SCALE: 1/4" = 1'-0" 1 CALD FEBRUARY 22, 2022 ARCH REVIEW COMMITTEE THIS SPACE RESERVED FOR ARCHITECT'S SEAL 02/22/2022 UNFORESEEN CONDITIONS If conditions or questions arise regarding the intent of construction documents, Contractor to contact architect immediately prior to proceeding with work in question. When, during the course of demolition activities, conditions are encountered (i.e., underground utilities; structural components) which could not have been foreseen or not specifically indicated on the drawings, shore and brace to a safe condition or support as required, cease activity and immediately notify the architect for direction. DERRINGTON BUILDING STUDIO BUILDING ELEVATION — EXISTING A3.01 The architectural works depicted herein are the sole property of Derrington Building Studio, PLLC and may not be constructed or used without his express written permission. No permission to modify or reproduce any of these architectural works, including without limitation the construction of any building, is expressed or should be implied from delivery of preliminary drawings or unsealed construction drawings. Permission to construct the building depicted in sealed construction drawings is expressly conditioned on the full and timely payment of all fees otherwise due Derrington Building Studio, PLLC and, in the absence of any written agreement to the contrary, is limited to a one-time use on the site indicated on these plans. © Tuesday, February 22, 2022 Derrington Building Studio, PLLC This copyright notice and title block are “copyright management information” under the Digital Millennium Copyright Act, and are included to deter and help detect copyright infringement. For this reason, this copyright management information must be included on all copies and derivatives of this work PROJECT CAULDRON COFFEE 2402 San Gabriel Street, Austin, TX 78705 The vicinity map on the left is not to scale and intended to help generally locate the project site within the context of Austin. THIS DOCUMENT IS INTENDED FOR REVIEW AND/OR COORDINATION ONLY. DO NOT USE FOR REGULATORY APPROVAL, PERMITTING, OR CONSTRUCTION. EXISTING STONE EXISTING WOOD PANELING EXISTING ROOF EXISTING RAFTERS EXISTING WOOD COLUMN 4x4 WOOD RAILING POST " 6 - ' 3 NEW WOOD RAILING 2x6 WOOD RAILING CAP 2x2 BALUSTERS @ 4" O.C. EXISTING STUCCO WALL EXISTING RAILING EXISTING WOOD BEAM 2x4 WOOD RAIL EXISTING STUCCO COLUMN EXISTING METAL COLUMN EXISTING RAILING EXISTING CONCRETE PORCH STEPS EXISTING STUCCO EXISTING STONE EXISTING ROOF EXISTING WOOD COLUMNS NEW WOODEN RAILING EXISTING STUCCO WALL EXISTING RAILING +22'-6" Roof (Bottom of Slab) +12'-6" Level Two (Top of Slab) ±0" Level One (Top of Slab) PROPOSED NORTH ELEVATION (RIGHT SIDE OF LOT) SCALE: 1/4" = 1'-0" 3 +22'-6" Roof (Bottom of Slab) SHEETNOTE • RCP These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the process and completion of this project. SHEETNOTE • EXTERIOR ELEVATION These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the process and completion of this project. SCHEDULES Reference schedules (MEP and/or architectural) for fixture types and specifications. ELEVATION HEIGHTS Any ceiling elevations indicated are above local finished floor level. +12'-6" Level Two (Top of Slab) FIRE ALAMRS Fire alarms are shown in elevations for location only. Refer to MEP for specifications and manufacturers instructions. LIGHT FIXTURES Light fixtures are shown in elevations for location only. refer to electrical drawings and specifications. INTERIOR COORDINATION Coordinate final light fixture height and location with interior designer. CROSS REFERENCE Some elevations contain angled planes and should not be scaled - refer to plans. DIMENSIONS All RCP dimensions are from finish to finish or to center line of fixture, unless noted otherwise. COURSING All window installations to course with existing brick. KEYNOTES Keynotes located on this sheet are for this sheet only. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. FIELD VERIFY GC to field verify all dimensions prior to construction and/or installation of any equipment, accessories, etc. If a discrepancy is identified, please notify DBS immediately. INTENTION Any demolition drawings and notes are provided for convenience and information only and are not intended to represent the comprehensive state of the building(s). Verify the existing state of the building(s) finishes and building systems. ±0" Level One (Top of Slab) INVESTIGATION The contractor shall make a thorough investigation of conditions where demolition is required and shall familiarize himself with the scope of demolition work required. PROPOSED EAST ELEVATION (FRONT OF LOT) SCALE: 1/4" = 1'-0" 1 CALD FEBRUARY 22, 2022 ARCH REVIEW COMMITTEE THIS SPACE RESERVED FOR ARCHITECT'S SEAL 02/22/2022 UNFORESEEN CONDITIONS If conditions or questions arise regarding the intent of construction documents, Contractor to contact architect immediately prior to proceeding with work in question. When, during the course of demolition activities, conditions are encountered (i.e., underground utilities; structural components) which could not have been foreseen or not specifically indicated on the drawings, shore and brace to a safe condition or support as required, cease activity and immediately notify the architect for direction. DERRINGTON BUILDING STUDIO BUILDING ELEVATION — PROPOSED A3.02 The architectural works depicted herein are the sole property of Derrington Building Studio, PLLC and may not be constructed or used without his express written permission. No permission to modify or reproduce any of these architectural works, including without limitation the construction of any building, is expressed or should be implied from delivery of preliminary drawings or unsealed construction drawings. Permission to construct the building depicted in sealed construction drawings is expressly conditioned on the full and timely payment of all fees otherwise due Derrington Building Studio, PLLC and, in the absence of any written agreement to the contrary, is limited to a one-time use on the site indicated on these plans. © Tuesday, February 22, 2022 Derrington Building Studio, PLLC This copyright notice and title block are “copyright management information” under the Digital Millennium Copyright Act, and are included to deter and help detect copyright infringement. For this reason, this copyright management information must be included on all copies and derivatives of this work PROJECT CAULDRON COFFEE 2402 San Gabriel Street, Austin, TX 78705 The vicinity map on the left is not to scale and intended to help generally locate the project site within the context of Austin. THIS DOCUMENT IS INTENDED FOR REVIEW AND/OR COORDINATION ONLY. DO NOT USE FOR REGULATORY APPROVAL, PERMITTING, OR CONSTRUCTION. EXISTING WOOD PANEL EXISTING STONE EXISTING STUCCO +22'-6" Roof (Bottom of Slab) EXISTING ROOF 4x4 WOOD RAILING POST NEW WOOD RAILING " 6 - ' 3 +12'-6" Level Two (Top of Slab) EXISTING RAFTERS EXISTING WOOD COLUMN 2x6 WOOD RAILING CAP 2x4 WOOD RAIL 2x2 BALUSTERS @ 4" O.C. EXISTING BEAM EXISTING METAL COLUMN EXISTING STUCCO COLUMN EXISTING RAILING EXISTING RAILING ±0" Level One (Top of Slab) EXISTING CONCRETE STEPS PROPOSED SOUTH ELEVATION (LEFT SIDE OF LOT) SCALE: 1/4" = 1'-0" 3 EXISTING STONE +22'-6" Roof (Bottom of Slab) EXISTING STUCCO WALL KEYNOTES Keynotes located on this sheet are for this sheet only. SCALE Do not scale the drawings. If a specific dimension is not given, contact DBS for clarification. SHEETNOTE • RCP These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the process and completion of this project. SHEETNOTE • EXTERIOR ELEVATION These notes are intended to clarify items that are specific to the graphic information on this particular sheet. Refer to the General Conditions near the front of these Construction Documents for critical information about the process and completion of this project. SCHEDULES Reference schedules (MEP and/or architectural) for fixture types and specifications. ELEVATION HEIGHTS Any ceiling elevations indicated are above local finished floor level. +12'-6" Level Two (Top of Slab) FIRE ALAMRS Fire alarms are shown in elevations for location only. Refer to MEP for specifications and manufacturers instructions. LIGHT FIXTURES Light fixtures are shown in elevations for location only. refer to electrical drawings and specifications. INTERIOR COORDINATION Coordinate final light fixture height and location with interior designer. CROSS REFERENCE Some elevations contain angled planes and should not be scaled - refer to plans. DIMENSIONS All RCP dimensions are from finish to finish or to center line of fixture, unless noted otherwise. COURSING All window installations to course with existing brick. FIELD VERIFY GC to field verify all dimensions prior to construction and/or installation of any equipment, accessories, etc. If a discrepancy is identified, please notify DBS immediately. INTENTION Any demolition drawings and notes are provided for convenience and information only and are not intended to represent the comprehensive state of the building(s). Verify the existing state of the building(s) finishes and building systems. ±0" Level One (Top of Slab) INVESTIGATION The contractor shall make a thorough investigation of conditions where demolition is required and shall familiarize himself with the scope of demolition work required. UNFORESEEN CONDITIONS If conditions or questions arise regarding the intent of construction documents, Contractor to contact architect immediately prior to proceeding with work in question. When, during the course of demolition activities, conditions are encountered (i.e., underground utilities; structural components) which could not have been foreseen or not specifically indicated on the drawings, shore and brace to a safe condition or support as required, cease activity and immediately notify the architect for direction. WEST ELEVATION SCALE: 1/4" = 1'-0" 1 CALD FEBRUARY 22, 2022 ARCH REVIEW COMMITTEE THIS SPACE RESERVED FOR ARCHITECT'S SEAL 02/22/2022 DERRINGTON BUILDING STUDIO BUILDING ELEVATION — PROPOSED A3.03 The architectural works depicted herein are the sole property of Derrington Building Studio, PLLC and may not be constructed or used without his express written permission. No permission to modify or reproduce any of these architectural works, including without limitation the construction of any building, is expressed or should be implied from delivery of preliminary drawings or unsealed construction drawings. Permission to construct the building depicted in sealed construction drawings is expressly conditioned on the full and timely payment of all fees otherwise due Derrington Building Studio, PLLC and, in the absence of any written agreement to the contrary, is limited to a one-time use on the site indicated on these plans. © Tuesday, February 22, 2022 Derrington Building Studio, PLLC This copyright notice and title block are “copyright management information” under the Digital Millennium Copyright Act, and are included to deter and help detect copyright infringement. For this reason, this copyright management information must be included on all copies and derivatives of this work PROJECT CAULDRON COFFEE 2402 San Gabriel Street, Austin, TX 78705 The vicinity map on the left is not to scale and intended to help generally locate the project site within the context of Austin. THIS DOCUMENT IS INTENDED FOR REVIEW AND/OR COORDINATION ONLY. DO NOT USE FOR REGULATORY APPROVAL, PERMITTING, OR CONSTRUCTION.