C.7.1 - 2500 Hartford Rd - Plans — original pdf

Backup

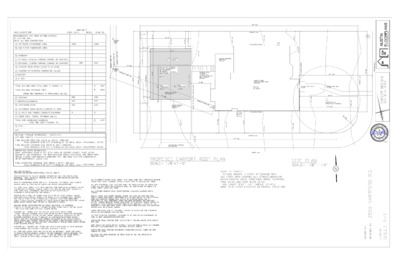

S N A L P R O O L F I N T S U A STATEOFTEXASREGISTEREDARCHITECT25173JBENJAMINPACKARD11/12/21 S N A L P R O O L F I N T S U A A-2 STATEOFTEXASREGISTEREDARCHITECT25173JBENJAMINPACKARD08/04/21 S N A L P R O O L F I N T S U A A-3 STATEOFTEXASREGISTEREDARCHITECT25173JBENJAMINPACKARD08/04/21 S N A L P R O O L F I N T S U A A-4 STATEOFTEXASREGISTEREDARCHITECT25173JBENJAMINPACKARD08/04/21 Building Code: International Residential Code Structural Engineering Design Provisions, 2021 Edition. 12. On top of the free draining, clean, crushed stone, place a vapor barrier. A material equivalent to a 28. Welding of reinforcement bars, when accepted by the structural engineer, shall conform to the reinforced paper product known as Moistop 395, manufactured by the Fortifiber Corporation, is suggested. Placement of the vapor barrier should be in accordance with the manufacturer's recommendations. American Welding Society Standard D1.4. Electrodes for shop and field welding of reinforcement bars shall conform to ASTM A233, Class E90XX. 29. Minimum concrete cover protection for reinforcement bars shall be as follows: (see ACI 318 Section GENERAL 1. 2. The design gravity loads are as follows: Superimposed Dead Loads (included, but not limited to): Mechanical and Ceiling: Roof Assemblies: Wood Floor Assemblies: Finishes: 10psf 10psf 10psf As required Live Loads (in accordance with 2015 IRC): Roof: Roof Net Uplift: Floor: Decks: Balconies: Attics w/ Light Storage: Guardrails and Handrails: Guardrails Infill Components: 20psf 10psf 40psf 40psf 60psf 20psf 200lb Point Load 50psf 3. 4. 5. 7. 8. 9. The structure has been designed to withstand the wind pressures specified in ASCE 7-10, using a 3 second gust basic wind speed of 115 miles per hour at a standard height of 14 feet above the ground in exposure B. The general contractor is responsible for fitting new work with existing construction. Information on existing buildings shown in the drawings was based upon the information supplied to Gogo Structural Engineers. This information is not as-built data and the actual as-built construction may differ from that represented in the drawings. Contractors shall verify all information. Variations from the dimensions indicated on the contract documents shall be brought to the attention of the architect and/or Gogo Structural Engineers, LLC. These drawings do not, nor are intended to, locate property lines, building set backs, nor height limitations. It is the contractor's responsibility to locate the building and construct it to, and within, applicable code restrictions. Further, it is the contractor's responsibility to address site drainage appropriate to the site and in consideration to adjoining properties. 6. Methods, procedures, and sequences of construction are the responsibility of the contractor and must satisfy the minimum requirements of the 2015 International Residential Building Code. The contractor shall take all necessary precautions to maintain and insure the integrity of the structure at all stages of construction. The general contractor and sub-contractors shall determine the scope of the structural work from the contract documents taken as a whole. The structural drawings shall not be considered separately for purposes of bidding the structural work. Due consideration shall be given to other structural work or work related to the structure, including necessary coordination described or implied by the architectural and mechanical drawings. Scales noted on the drawings are for general reference only. No dimensional information shall be obtained by direct scaling of the drawing. The general contractor is responsible for coordination of all resulting revisions to the structural system or other trades as a result of acceptance of contractor proposed alternatives or substitutions. 10. Structural members have been located and designed to accommodate the mechanical equipment openings specified by the mechanical consultant. Any submissions resulting in revisions to the structure shall be the responsibility of the contractor to coordinate with Gogo Structural Engineers. 11. Principal openings in the structure are indicated on the contract documents, refer to the architectural, mechanical, electrical, and plumbing drawings for sleeves, curbs, inserts, etc. not herein indicated. Openings in slabs with a maximum side dimension or diameter of 12 inches or less shall not require additional framing or reinforcement, unless noted otherwise. The location of sleeves or openings in structural members shall be submitted to Gogo Structural Engineers for review. FOUNDATION BUILDING PAD 1. Due to the absence of a site specific subsurface analysis and report from a registered Geotechnical Engineer, the foundation design is based on assumptions and/or site observations of the existing site conditions. These assumptions may not be verifiable without the expending of additional fees. Foundation conditions noted during construction that differ than those shown in the structural drawings shall be noted to the Structural Engineer before further construction is to proceed. 2. Within the foundation outline and 2'-0" beyond, remove all fat clay and/or unstable, completely weathered limestone strata, all organics (I.E., roots, trees, grass, and other humus), any building foundations or rubble, and any other deleterious materials to a minimum depth of 12". 3. The floor subgrade shall be properly compacted and proofrolled and shall be free of standing water, mud and frozen soil. 4. A vapor barrier with a performance equivalent to a 10 mil stego wrap vapor barrier shall be placed beneath the slab on grade and wrap around perimeter beams. 5. In areas where limestone is exposed at the cut surface, remove a depth of limestone to provide for at least 6" of compacted select fill. In areas where soil or completely weathered limestone is exposed, scarify at least six inches of the cut soil subgrade and recompact to at least 95% of the maximum dry density determined using Texas State Department of Highways and Public Transportation (SDHPT) Test Method TEX-113-E conducted with a laboratory compacted effort of 6.63 FT lbs/cu. in. Hold water contents within ± 2%. 6. Bring the building pads to grade with select material conforming to the following: Retained on 2-1/2" screen Retained on 7/8" screen Retained on 3/8" screen Retained on 1/4" screen Retained on #40 mesh sieve 0% 5% - 50% 25% - 65% 35% - 75% 60% - 90% 13. In areas beneath the slab where compacted fill depths exceed 4'-0", all utilities, exhaust lines and conduit, including but not limited to plumbing, gas, and electric conduit lines, shall be adequately attached to the underside of the concrete floor slab. Means and method of attachment shall be the responsibility of the contractor and do not fall under the scope of these structural documents. 14. The foundation design assumptions do allow for a limited amount of potential vertical rise that will not affect structural stability. This allowance in design does not cover architectural, mechanical, electrical or plumbing features. 15. Refer to project specifications for all information concerning foundation construction. The contractor shall perform excavations, footing construction and preparation of the subgrade in accordance with the project specifications. 1. Concrete in the following areas shall have the following compressive strength (f'c) at 28 days: CONCRETE Spread footings Grade beams Slabs on grade Walls 3000 PSI 3000 PSI 3000 PSI 3000 PSI 2. All concrete mix designs shall be reviewed and approved by the testing agency prior to sending to the engineer of record for approval. 7.7 for conditions not noted) Concrete exposed to weather #5 bars and smaller All other bars Concrete cast against earth Grade beams: Top Board formed sides Earth formed sides Bottom Slabs on grade: Single layer or top layer Bottom layer cast against soil Bottom layer not cast against soil Columns Pilasters & plinths Slabs on metal forms Walls below grade (backfilled side) Walls below grade (no backfill) 1 - 1/2 inches 2 inches 3 inches 1 - 1/2 inches 2 inches 3 inches 3 inches 2 inches 3 inches 2 inches 1 - 1/2 inches 2 inches 3/4 inches (top) 2 inches 3/4 inches 3. Use the following cementitious materials, of the same type, brand and source throughout the corners. 30. Horizontal wall steel shall be continuous with 90 degree bends and 12" returns along each wall at Project: Portland Cement: ASTM C 150, Type I/II 4. Fly ash may be used as a pozzolan to replace a portion of the portland cement in a concrete mix, subject to the approval of the structural engineer. Fly ash, when used, shall conform to ASTM C618, Type C or F. Concrete mixes using fly ash shall be proportioned to account for the properties of the specific fly ash used and to account for the specific properties of the fly ash concrete thus resulting. The ratio of the amount of the fly ash to the total amount of fly ash and cement in the mix shall not exceed 40 percent. 5. Use the following normal-weight aggregates: ASTM C 33, coarse aggregate or better, graded. Provide aggregates from a single source conforming to the following: Maximum Coarse-Aggregate Size: typically 3 Fine Aggregate: free of materials with deleterious reactivity to alkali in cement 4" nominal diameter 6. Lightweight aggregate shall conform to ASTM C 330. 7. Water shall conform to ASTM C 94/C 94M and be potable. 8. Admixtures if used shall be subject to the approval of the structural engineer. 9. Mixing, transporting, and placing of concrete shall conform to ACI 301 and ASTM C 94. 10. Conformance to ACI 305.1 "Specification for Hot Weather Concreting" is required when air temperature is above 90 deg F. 11. Conformance to ACI 306 "Cold Weather Concreting" is required when a period for more than three (3) consecutive days, the average daily air temperature is below 40 deg F and the air temperature is not greater than 50 deg F for more than one-half of any 24 hour period. 12. The fire protection rating for this project is based upon the use of normal weight aggregate concrete made with carbonate aggregates. Carbonate aggregates consist mainly of calcium or magnesium carbonate, e.g., limestone or dolomite, and contain 40 percent or less quartz, chert and flint. 13. General contractor shall notify and schedule a pre pour inspection with Gogo Structural Engineers a minimum of 72 hours prior to placement of concrete. 14. During construction, the contractor shall provide temporary shoring of walls which are ultimately supported top and bottom. Such shoring shall not be removed until the supporting elements are in place, the concrete in the walls and supporting elements has attained the specified 28 day compressive strength (fc') and compaction of the backfill against the wall has been completed. 15. A gravity drainage system is required to prevent the build-up of hydrostatic pressure behind the walls. 16. Detailing of concrete reinforcement bars and accessories shall conform to the recommendations of ACI 315 "Details and Detailing of Concrete Reinforcement" and ACI SP-66 "Detailing Manual". Placing of reinforcing bars shall conform to the recommendations of ACI 315R "Manual of Engineering" and placing drawings for reinforced concrete structures" and CRSI "Manual of Standard Practice". 17. No conduit or piping larger than 1" I.D. shall be run in structural concrete members unless shown on structural drawings. 18. All pipe sleeves in concrete members shall be schedule 40 pipe unless shown otherwise on the structural drawings. Location of the sleeves shall be as approved by the Structural Engineer. Provide 3 additional stirrups each side of each sleeve in beams and space as directed by the Engineer. 19. Reinforced steel shall be deformed new billet steel bars in accordance with A.S.T.M. Specification A615 Grade 60. 31. Concrete pours shall not exceed 5000 square feet or 100 linear feet on any side. POST-INSTALLED ANCHORS Post-installed anchors shall only be used where specified on the drawings. Contractor shall obtain approval from Engineer of Record prior to using post-installed anchors for missing or misplaced cast-in-place anchors. Care shall be given to avoid conflicts with existing rebar. Holes shall be drilled and cleaned per the manufacturer's instructions. Anchors shall be installed per the manufacturer's installation instructions at not less than minimum edge distances and/or spacings indicated in the manufacturer's literature. 4. Unless specified otherwise, anchors shall be embedded in the appropriate substrate with a minimum embedment of 8 times the nominal anchor diameter or the embedment required to support the intended load. Contractor to notify engineer prior to installation for anchor product approval chosen from list below. Substitution requests, for products other than those specified, shall be submitted to the Engineer with calculations that are prepared & sealed by a registered Professional Engineer showing that the substituted product will achieve an equivalent capacity using the appropriate design procedure required by the Building Code. Contact Simpson Strong-Tie at (800) 999-5099 or HILTI at (800) 879-6000 X7980 for product related questions and availability. Acceptable products for installation in concrete are as follows: Expansion anchors shall be: Simpson Strong-Tie "Strong-Bolt" per ICC ESR-1771 Simpson Strong-Tie "Strong-Bolt 2" per ICC ESR-3037 HILTI "Kwik Bolt TZ" per ICC ESR-1917 Screw anchors shall be: Simpson Strong-Tie "Titen HD" per ICC ESR-2713 HILTI "Kwik HUS-EZ" per ICC ESR-3027 Adhesive anchors shall be: Simpson Strong-Tie "SET-XP Epoxy-Tie Adhesive" per ICC ESR-2508 HILTI "RE500-SD Epoxy Adhesive" per ICC ESR-2322 HILTI "HY 200 Adhesive" per ICC ESR-3013 Powder Actuated Fasteners shall be: Simpson Stong-Tie "Powder-Driven Fasteners" per ICC ESR-2138 HILTI "X-U Powder-Driven Fasteners" per ICC ESR-2269 Acceptable products for installation in grout filled concrete block are as follows: Expansion anchors shall be: Simpson Strong-Tie "Wedge-All" per ICC ESR-1396 HILTI "Kwik Bolt 3" per ICC ESR-1385 Screw anchors shall be: Simpson Strong-Tie "Titen HD" per ICC ESR-1056 Adhesive anchors shall be: Simpson Strong-Tie "SET Epoxy-Tie Adhesive" per ICC ESR-1772 HILTI "HIT-HY150 Adhesive Anchoring System" per ICC ESR-5193 Material passing the #40 sieve shall meet the following plasticity requirements: 22. All hooks and bends in reinforcing bars shall conform to ACI Standards unless shown otherwise. PASSING No. 40 Sieve 25% - 40% 10% - 25% MAXIMUM MINIMUM Plasticity Index 15 20 Plasticity Index 3 4 23. Reinforcement designated as "continuous" may be spliced using Type "B" splices. Reinforcement bar splice lengths in beams which are located at the centerline of supports for bottom bars and at mid-span for top bars may be 36 bar diameters, unless noted otherwise. Provide standard ACI hooks for top and bottom bars at discontinuous ends of all grade beams. Sandy loam is not acceptable fill material. 24. Vertical joints may occur at center of spans at locations reviewed by Gogo Structural Engineers. Expansion anchors shall be: Simpson Strong-Tie "Strong-Bolt" per ICC ESR-1771 HILTI "Kwik Bolt TZ" per ICC ESR-1917 Simpson Strong-Tie "Strong-Bolt 2" per ICC ESR-3037 Screw anchors shall be: Simpson Strong-Tie "Titen HD" per ICC ESR-2713 TIMBER 20. All stirrups shall be Grade 60 with standard 90 degree hooks. 10. Acceptable products for installation in the soffit of concrete over profile metal deck are as follows: 21. Provide 2-#5 x 4'-0" "L" shaped bars top and bottom at all corners and "T" intersections of beams. 7. Contractor shall certify the compaction of the select material to at least 95% of the maximum dry density as determined using SDHPT Test Method TEX-113-E conducted with a laboratory compactive effort of 6.63 ft lbs/cu. in. Hold water contents to within + 2% of the optimum, and maintain compacted lift thickness to 6" or less. 8. On top of the compacted, select fill or the cut excavation bottom, place a capillary moisture barrier / drainage layer (minimum thickness of four inches) of free draining, clean, crushed stone with sizes ranging mostly between 1/4 and 1/2 inch. A material conforming to ASTM C 33, Grade 67, is suggested since it is readily available in the central Texas area. The purpose of this layer is to: A: B: Provide satisfactory support for slab reinforcement, and Break the transmission of capillary moisture to the underside of the slab. 25. Horizontal construction joints in concrete pours shall be permitted only where indicated on the the SPIB. drawings. All construction joints shall be made in the center of spans - see drawings for typical detail. The location of the construction joints shall be as approved by the Architect and the Structural Engineer. Additional reinforcing at construction joints shall be as specified by the Engineer without additional cost to the owner. 26. Construction joints between piers and pier caps, footings and walls or columns, or walls, columns, beams, and the floor system they support shall be prepared by roughening the contact surface to a full amplitude of approximately 1/4 inch leaving the contact surface clean and free of laitance. 27. Reinforcement bars shall not be tack welded, welded, heated, or cut unless indicated on the contract documents or reviewed by the structural engineer. 1. Unless otherwise noted, all structural framing lumber shall be clearly marked No. 2 Southern Pine by All wood studs shall be full height without intermediate plate line unless detailed otherwise. Solid 2x blocking shall be provided at end and point of support of all wood joists and shall be placed between supports in rows not exceeding 8'-0" apart. All walls shall have 2x solid blocking at 4'-0" o.c. maximum vertically for plate heights exceeding 8'-0". End nail with 2-16d nails or side toe nail with 1-16d nails. 4. Decking: All plywood decking shall be APA Rated Sheathing, Exposure 1. 3 4" T&G for floors with 48 24 8" with clips for roofs with 40 Span Rating, 5 supported edges, 10d at 12" o.c. at all intermediate supports (1 5 plywood decking shall be staggered. 20 Span Rating, use 10d common nails at 6" o.c. at all 8" min. penetration). All joints in 1. 2. 3. 5. 6. 7. 8. A. - - - B. - - C. - - - D. - - 9. A. - - B. - C. - - A. - - - B. - 2. 3. All exterior walls shall be solid clad with 15 32" plywood APA Rated Sheathing, Exposure 1, from the top plate to the bottom plate. Attach to frame using 10d nails spaced at 6" o.c. along edges and at 8" min. penetration). Staple option: 1-3 12" at intermediate studs (1-5 at 8" at intermediate studs (1" min. penetration). Staples shall have a minimum crown width of 7 and shall be installed with their crowns parallel to the long dimension of the framing members. (UNLESS NOTED OTHERWISE IN THE SHEARWALL SCHEDULE AND LATERAL BRACING PLAN) 4" 16 gage at 3" along edges and 16" All framing members framing into the side of a header shall be attached using metal joist hangers. Place a single plate at the bottom and a double plate at the top of all stud walls. If nailing is not noted or shown otherwise on plans or details, nailing schedule shall be as follows: 5. 6. 7. 8. 1. 2. 3. 4. 5. Connection Nailing Joist to sill or Girder - toenail.............................................(3) - 8d Bridging to joist - -toenail each end...................................(2) - 8d Sole plate to joist or blocking - typ. face nail.....................16d at 16" o.c. or brace wall panel................(3) - 16d Top plate to stud - endnail/endnail....................................(2) - 16d Stud to sole plate - toenail.................................................(4) - 8d or end nail.. (2) - 16d 6. Double studs - face nail......................................................16d at 24" o.c. 7. Double top plates - typical face nail...................................16d at 16" o.c. or lap splice (8) 16d Blocking between joists and/or rafters - toenail to dbl top plate ................(4) - 8d Blocking between cantilevered joists - toenail to dbl top plate ...................(4) - 8d 8. 9. 10. Rafters to top plate w/ overhang < 2'-0" - toenail.............(3) - 8d 11. Rafters to top plate w/ overhang > 2'-0" but < 3'-6"............... provide Simpson h3 hurricane ties 12. Rim joist to top plate - toenail..........................................8d at 16" o.c. 13. Top plates (laps and intersections) - face nail..................(2) - 16d 14. Continuous header (two pieces) .....................................16d at 16" o.c. staggered along each edge 15. Ceiling joists to plate - toenail..........................................(3) - 8d 16. Continuous header to stud - toenail................................(4) - 8d 17. Ceiling joists (laps over partitions) - face nail..................(3) - 16d 18. Ceiling joists to parallel rafters - face nail........................(3) - 16d 19. Rafter to plate - toenail....................................................(3) - 8d 20. 1" diagonal brace to each stud and plate - face nail........(2) - 8d 21. Built-up corner studs.......................................................16d at 24" o.c. 22. Built-up girder and beams - face nail at top & bottom staggered on opposite sides......20d at 32" o.c. face nail at ends and at each splice....................(2) - 20d 23. 2" planks - at each bearing...............................................16d 24. Collar tie to rafter - face nail............................................(3 - 10d Jack rafter to hip - toenail................................................(3) - 10d 25. 26. Roof rafter to 2x ridge beam - toenail.............................(2) - 16d 27. Joist to band joist - face nail.............................................(3) - 16d 28. Ledger strip - face nail......................................................(3) - 16d face nail...........(2) - 16d face nail...........(2) - 16d 29. Plywood Floor, wall and roof sheathing (to framing): 3 1 1-1 8" and less........................................................................8d 2", 5 4"...................................................................10d 4"...................................................................10d 8" and 3 8" and 1-1 30. Floor plywood: Nails spaced at 6" o.c. at edges and at all blocking between joist. 12" o.c. at intermediate supports. 31. Roof plywood: Nails spaced at 6" o.c. at edges and at all blocking between rafters. 12" o.c. at intermediate supports, "H" clips at 24" o.c. 32. Panel siding (to framing): 1 5 2" or less.....................................................................6d 8"................................................................................8d *Corrosion-resistant siding or casing nails 33. Built-up columns (unless detailed otherwise): COLUMN TYPE FASTENERS 2 - 2X4....................1 row of 10d nails each side @ 8" o.c. staggered 3 - 2x4....................1 row of 30d nails each side @ 8" o.c. staggered 4 - 2x4....................1 row of 3 2 - 2x6....................2 rows of 10d nails each side @ 8" o.c. 3 - 2x6....................2 rows of 30d nails each side @ 8" o.c. 4 - 2x6....................2 rows of 3 8" dia. through bolts @ 8" o.c. staggered 8" dia. through bolts @ 8" o.c. 9. Wood nailer attachment to steel members 3 8" thick or less: attach 2x nailer with 0.177" diameter x 8" long HILTI X-AL-H powder actuated fasteners spaced at 8" o.c. staggered or with an approved 1-7 alternative. 10. Exterior sole plates and interior shear wall plates shall be attached to concrete foundations with 1 2" Ø anchor bolts spaced at a maximum of 6'-0" o.c. There shall be a minimum of 2 bolts per plate section with one bolt located not more than 12" or less than 7 bolt diameter from each end of the plate section. At interior load bearing walls not part of the lateral bracing system sole plates shall be anchored in same manner or with 0.177" Ø x 2 2 8" long Hilti X-AL-H power actuated fasteners at 16" o.c. or with an approved alternative. 11. Common wire nails or spikes, or galvanized box nails shall be used for all framing unless noted otherwise. 12. Fasteners, including bolts, lag screws, and drift pins with diameters 3 8" or greater shall conform to SAE J 429 Grade 1. Bolts shall be installed per AMSI/ASME Standard B18.2.1. LAMINATED VENEER LUMBER (LVL) 1. All laminated veneer lumber (LVL) shall be of species so. pine, Grade 1.9E & shall provide the following allowable design values: 2600 psi in bending 285 psi in horizontal shear 1,900,000 psi in modulus of elasticity 2. Multiple plies shall be attached together with a minimum of: 2 rows of 10d common nails @ 12" o.c., 2" from top and bottom. 3 rows of 10d common nails @ 12" o.c. for beam depths 14" or greater, 2" from top and bottom. For multiple plies of 4, 2 rows of 1 and bottom. 2" Ø A307 bolts w/ washers @ 16" o.c., 2" from top 3. 4. Load must be applied evenly across entire beam width, u.n.o. If unable, follow manufacturer specifications for side-loaded beams or contact engineer. LVL beams shall only be penetrated in the middle third span. Do not notch LVL beams without approval from Engineer. The maximum allowable round hole size is 2" for beams 7 1 4" in depth or more. Rectangular holes are not allowed. Holes shall be located in the middle third of the depth & spaced a minimum of 2x diameter of the largest hole. · · · · · · 10/16/2021 FIRM NO. 17948 COORDINATION 1. All coordination efforts, scheduling, or structural clarification of plan from general contractors, sub contractors, architects, and owners or any persons shall first email engineer of record with sufficient detail about the subject at victor@gogo-llc.com. If applicaple, send redlined structural plans or architect plans so engineer can begin reviewing and come up with a solution. 2. Only certain of the required sleeve openings in structural framing component members, and only certain of the required framed openings in and/or through structural assembly are indicated on the structural series drawings. However, all sleeves, inserts and openings, including frames and/or sleeves, therefore, shall be provided for passage, provision and/or incorporation of the work of the contract, including but not limited to Mechanical, Electrical, and Plumbing work. The providing for sleeves or framed openings shall include the verification of sizes, alignment, dimension, position, locations, elevations, and grades as required to serve the intended purpose. Openings not indicated on the structural series drawings, but required as above, shall have been approved by the engineer. 3. 4. 5. 6. 7. Refer to Architectural, Mechanical, Electrical, and Plumbing series drawings for floor elevations, slopes, drains, and location of depressed and elevated floor areas. Structural series drawings shall be compared with drawings of other series; differences shall be referred to the Architect for instruction. Compatibility of accommodation and provision for building equipment supported on or from structural components shall be verified as to size, dimension, clearances, accessibility, weights, and reaction with the equipment for which the accommodation has been designed prior to submission of shop drawings and submittal data for each equipment and for structural components; differences shall be referred to the Architect for review and approval and notation. The structural system of this building is designed to perform as a completed unit. Prior to completion of the structure, structural components may be unstable and it is the responsibility of the contractor, or the client in the absence of a general contractor, to provide temporary shoring and/or bracing as required for the stability of the incomplete structure and for the safety of all on-site personnel. The remodeling and/or rehabilitation of an existing building requires that certain assumptions be made regarding existing conditions, and because some of these assumptions may not be verifiable without expending additional sums of money or destroying an otherwise adequate or serviceable portion of the structure. The client agrees to the fullest extent permitted by law, to indemnify and hold the Design Professional harmless from any claim, liability, or cost (including reasonable attorneys' fees and cost of defense) for injury or economic loss arising or allegedly arising out of the professional services provided under this agreement, excepting only those damages, liabilities for costs the attributable to the negligence or willful misconduct of the Design Professional. 06/27/2021 FIRM NO. 17948 1'-0" 1'-0" 4'-10" 6'-8" 12'-6" 1'-0" 28'-0" 1'-0" . 1 3 S / 1 3/S3.1 VERIFY 3/S3.1 . 1 3 S / 3 " 0 - ' 5 3 " 1 - ' 1 1 1/S3.1 " 0 - ' 1 " 0 1 - ' 9 " 0 - ' 1 " 0 - ' 1 " 0 - ' 1 " 1 - ' 0 1 . 1 3 S / 3 7/S3.1 . 1 3 S / 1 FOUNDATION PLAN 1 / 4" = 1' - 0" FOR 22" X 34" (REDUCE BY 50% FOR 11" X 17") . 1 3 S / 4 T F / " 4 1 P L S . 1 3 S / 6 VARIES VARIES 5/S3.1 F R A M I N G P L A N N O T E S ALL ROOF RAFTERS SHALL BE 2X6 SPACED @ 24" O.C. W/ A MAXIMUM UNSUPPORTED HORIZONTAL SPAN OF 11'-0" OR 2X8 @ 24" O.C. WITH A MAXIMUM SPAN OF 14'-0", U.N.O. ON PLAN. 1/S3.1 RIDGE MEMBERS SHALL BE 2X8 OR 2X10 WITH A MAXIMUM UNSUPPORTED HORIZONTAL SPAN OF 4'-0" U.N.O. ON PLAN. 1. 2. 3. 5. 7. 8. ALL LOAD BEARING WALLS SHALL BE 2X4 STUDS @ 16" O.C. FOR EXTERIOR WALLS AND 2X4 STUDS @ 16" O.C. FOR INTERIOR WALLS AND ARE INDICATED AS: 4. ALL WALLS SHOWN ARE FROM FLOOR BELOW. IN THE ABSENCE OF CEILING FRAMING AND/OR VAULTED CEILINGS, ALL WALLS INCLUDING GABLE END WALLS SHALL BE FRAMED FULL HEIGHT WITH NO INTERMEDIATE PLATES. 6. CEILING JOISTS SHALL MEET OR EXCEED THE FOLLOWING CRITERIA: JOIST SIZE SPACING MAXIMUM SPAN 2X6 24" O.C. 11'-0" 14'-2" 2X8 24" O.C. 2X10 24" O.C. 16'-11" *DOUBLE ALL CEILING JOISTS SUPPORTING ROOF RIDGE LOADS ALL HEADERS SHALL BE FULLY SUPPORTED BY 2-STUD COLUMNS, U.N.O. ON PLAN. HEADERS MARKED (TYP. HDR) SHALL BE (3) 2X6 MIN. @ 2X6 STUD WALLS & (2) 2X8 MIN. @ 2X4 STUD WALLS. ALL JOIST HANGERS ARE INDICATED AS AND SHALL BE THE FOLLOWING BY SIMPSON STRONGTIE*: - 2X10.................................. LUS210 - 2X FLOOR TRUSS............... PER TRUSS MANUFACTURER'S SPEC. - (2) 2X12............................. LUS210-2 - (2) 1 3 *ALL HANGERS SHALL BE INSTALLED TO MANUFACTURER'S SPECIFICATIONS 8" LVL........... IUS3.56/11.88 4" X11 7 9. SEE SHEET S0.0 FOR ADDITIONAL NOTES. 10/16/2021 FIRM NO. 17948 TYP HDR TYP HDR VAULTED TYP HDR G N I L I E C M R O F S E S S U R T F O D R O H C M O T T O B (2)1 3 4" X 16" LVL HDR CEILING FRAMING PLAN 1 / 4" = 1' - 0" FOR 22" X 34" (REDUCE BY 50% FOR 11" X 17") 1. 2. 3. 5. 7. 8. F R A M I N G P L A N N O T E S ALL ROOF RAFTERS SHALL BE 2X6 SPACED @ 24" O.C. W/ A MAXIMUM UNSUPPORTED HORIZONTAL SPAN OF 11'-0" OR 2X8 @ 24" O.C. WITH A MAXIMUM SPAN OF 14'-0", U.N.O. ON PLAN. RIDGE MEMBERS SHALL BE 2X8 OR 2X10 WITH A MAXIMUM UNSUPPORTED HORIZONTAL SPAN OF 4'-0" U.N.O. ON PLAN. ALL LOAD BEARING WALLS SHALL BE 2X4 STUDS @ 16" O.C. FOR EXTERIOR WALLS AND 2X4 STUDS @ 16" O.C. FOR INTERIOR WALLS AND ARE INDICATED AS: 4. ALL WALLS SHOWN ARE FROM FLOOR BELOW. IN THE ABSENCE OF CEILING FRAMING AND/OR VAULTED CEILINGS, ALL WALLS INCLUDING GABLE END WALLS SHALL BE FRAMED FULL HEIGHT WITH NO INTERMEDIATE PLATES. 6. CEILING JOISTS SHALL MEET OR EXCEED THE FOLLOWING CRITERIA: JOIST SIZE SPACING MAXIMUM SPAN 2X6 24" O.C. 11'-0" 2X8 24" O.C. 14'-2" 2X10 24" O.C. 16'-11" *DOUBLE ALL CEILING JOISTS SUPPORTING ROOF RIDGE LOADS ALL HEADERS SHALL BE FULLY SUPPORTED BY 2-STUD COLUMNS, U.N.O. ON PLAN. HEADERS MARKED (TYP. HDR) SHALL BE (3) 2X6 MIN. @ 2X6 STUD WALLS & (2) 2X8 MIN. @ 2X4 STUD WALLS. ALL JOIST HANGERS ARE INDICATED AS AND SHALL BE THE FOLLOWING BY SIMPSON STRONGTIE*: - 2X10.................................. LUS210 - 2X FLOOR TRUSS............... PER TRUSS MANUFACTURER'S SPEC. - (2) 2X12............................. LUS210-2 - (2) 1 3 *ALL HANGERS SHALL BE INSTALLED TO MANUFACTURER'S SPECIFICATIONS 8" LVL........... IUS3.56/11.88 4" X11 7 9. SEE SHEET S0.0 FOR ADDITIONAL NOTES. 0 1 X 2 ) 2 ( 0 1 X 2 ) 2 ( 10/16/2021 FIRM NO. 17948 TYP HDR TYP HDR GABLE ROOF GIRDER TRUSS . 1 3 S / 3 E N I L E G D R I F O O R R O S S I C S . . C O " 4 2 @ S E S S U R T . . C O " 4 2 @ S E S S U R T F O O R E L B A G 1. 2. 3. 5. 7. 8. F R A M I N G P L A N N O T E S ALL ROOF RAFTERS SHALL BE 2X6 SPACED @ 24" O.C. W/ A MAXIMUM UNSUPPORTED HORIZONTAL SPAN OF 11'-0" OR 2X8 @ 24" O.C. WITH A MAXIMUM SPAN OF 14'-0", U.N.O. ON PLAN. RIDGE MEMBERS SHALL BE 2X8 OR 2X10 WITH A MAXIMUM UNSUPPORTED HORIZONTAL SPAN OF 4'-0" U.N.O. ON PLAN. ALL LOAD BEARING WALLS SHALL BE 2X4 STUDS @ 16" O.C. FOR EXTERIOR WALLS AND 2X4 STUDS @ 16" O.C. FOR INTERIOR WALLS AND ARE INDICATED AS: 4. ALL WALLS SHOWN ARE FROM FLOOR BELOW. IN THE ABSENCE OF CEILING FRAMING AND/OR VAULTED CEILINGS, ALL WALLS INCLUDING GABLE END WALLS SHALL BE FRAMED FULL HEIGHT WITH NO INTERMEDIATE PLATES. 6. CEILING JOISTS SHALL MEET OR EXCEED THE FOLLOWING CRITERIA: JOIST SIZE SPACING MAXIMUM SPAN 2X6 24" O.C. 11'-0" 2X8 24" O.C. 14'-2" 2X10 24" O.C. 16'-11" *DOUBLE ALL CEILING JOISTS SUPPORTING ROOF RIDGE LOADS ALL HEADERS SHALL BE FULLY SUPPORTED BY 2-STUD COLUMNS, U.N.O. ON PLAN. HEADERS MARKED (TYP. HDR) SHALL BE (3) 2X6 MIN. @ 2X6 STUD WALLS & (2) 2X8 MIN. @ 2X4 STUD WALLS. ALL JOIST HANGERS ARE INDICATED AS AND SHALL BE THE FOLLOWING BY SIMPSON STRONGTIE*: - 2X10.................................. LUS210 - 2X FLOOR TRUSS............... PER TRUSS MANUFACTURER'S SPEC. - (2) 2X12............................. LUS210-2 - (2) 1 3 *ALL HANGERS SHALL BE INSTALLED TO MANUFACTURER'S SPECIFICATIONS 8" LVL........... IUS3.56/11.88 4" X11 7 9. SEE SHEET S0.0 FOR ADDITIONAL NOTES. 2 1 X 2 ) 2 ( 2 1 X 2 ) 2 ( 2/S3.1 2/S3.1 GABLE ROOF GIRDER TRUSS (2)1 3 4" X 16" LVL . 1 3 S / 3 ROOF FRAMING PLAN 1 / 4" = 1' - 0" FOR 22" X 34" (REDUCE BY 50% FOR 11" X 17") 10/16/2021 FIRM NO. 17948 E L U D E H C S 2 E N I L E C A R B L L A W R A E H S E E S ) " 0 1 - ' 1 1 ( 1 1 (28'-0") BRACE LINE 3 SEE SHEAR WALL SCHEDULE E L U D E H C S 1 E N I L E C A R B L L A W R A E H S E E S ) " 0 - ' 5 3 ( 1 2 . 5 S D 4 - S U D H 1 (5'-10") 2 . 5 S D 4 - S U D H FIRST LEVE WALLS LATERAL BRACING PLAN 1 / 4" = 1' - 0" FOR 22" X 34" (REDUCE BY 50% FOR 11" X 17") 10/16/2021 A N C H O R A G E P L A N N O T E S L A T E R A L B R A C I N G P L A N N O T E S H D U 5 - S D S 2 . 5 FOR EXAMPLE, INDICATES REQUIRED HOLDOWN AT ENDS OF LATERAL BRACES. SEE TYPICAL HOLDOWN DETAIL FOR ANCHOR BOLT AND FASTENING REQUIREMENTS. SEE SHEET S3.0 FOR TYPICAL HOLDDOWN DETAIL. SEE LATERAL BRACING PLANS FOR ADDITIONAL INFORMATION. 1. 1 (X'-X") AND MINIMUM LENGTH. SEE SHEAR WALL SCHEDULE THIS SHEET FOR SHEATHING TYPE AND FASTENING REQUIREMENTS. INDICATES SHEAR WALL TYPE 2. SHEATHING AND FASTENING REQUIREMENTS MAY NOT BE SUBSTITUTED WITH ANOTHER SYSTEM WITHOUT PRIOR APPROVAL OF GOGO STRUCTURAL ENGINEERS LLC SEE SHEET S0.0 FOR ADDITIONAL NOTES. 3. SEE FRAMING PLANS FOR ADDITIONAL INFORMATION. 1. 2. 3. 4. SW MARK 1 2 15 32" SHEATHING (ONE SIDE, BLOCKED) 15 32" SHEATHING (ONE SIDE, BLOCKED) BRACE LINE 4 SEE SHEAR WALL SCHEDULE SHEATHING FASTENER AT PANEL EDGES FASTENER AT PANEL INTERIOR ANCHOR BOLTS* SILL ANCHORS A35 CLIP SPACING ASD WIND SHEAR WALL CAPACITY HOLDOWN ANCHOR 8d @ 6" O.C. 8d @ 12" O.C. 16d @ 4" O.C. 16" O.C. 392 PLF SEE PLAN 8d @ 4" O.C. 8d @ 12" O.C. 10" O.C. 602 PLF SEE PLAN FIRM NO. 17948 S H E A R W A L L S C H E D U L E 5 8" Ø @ 48" O.C. 5 8" Ø @ 40" O.C. SIMPSON SDS 4" Ø X 6" @ 6" O.C. 1 1 (XX'-XX") NOTE: - DO NOT CUT REINFORCEMENT TO ACCOMMODATE PIPE. - IF CLEARANCES SHOWN BELOW ARE SATISFIED, BEAM DEPTH DOES NOT NEED TO BE INCREASED; HOWEVER, THE ADDITIONAL STIRRUPS MUST BE ADDED. 3 " C L R (2) #5 X 4'-0" MID DEPTH OF SLAB (2) #5 CONT. TOP & BOT. W/ #3 STIRRUPS @ 24" O.C. . I N M " 0 - ' 1 . I N M " 6 PROVIDE (2) ADDITIONAL STIRRUPS EA. SIDE OF PENETRATION #3 @ 16" O.C. EA. WAY @ MID-DEPTH OF SLAB, TYP. HORIZONTAL PIPE 2" O.D. OR LARGER FIELD BEND BOTTOM REINFORCEMENT AS REQUIRED TO MAINTAIN 6" CLEARANCE FROM BOTTOM OF BEAM IF CONDUIT MUST BE PLACED IN SLAB, PROVIDE #3 x 36" LONG, AS SHOWN, PERPENDICULAR TO CONDUIT AND BETWEEN EACH EXISTING SLAB BAR. (SLAB CRACKING MAY STILL OCCUR) EQ. EQ. 6" " 6 4" W /135° H O O K 4 " W / 1 3 5 ° H O O K PREFERRED LOCATION OF ELECTRICAL CONDUIT #3 @ 16" O.C. EA. WAY @ MID-DEPTH OF SLAB, TYP. 10 MIL VAPOR RETARDER, TYP. COMPACTED SELECT FILL, TYP. 1 PLAN @ INSIDE CORNER 3 / 4" = 1' - 0" 2 HORIZONTAL PENETRATION OF GRADE BEAM 3 / 4" = 1' - 0" 3 SLAB REINFORCING @ CONDUIT 1 1 / 2" = 1' - 0" 4 STIRRUP BAR BENDING DETAIL ALTERNATIVES 1 1 / 2" = 1' - 0" BAR SIZE #3 #4 #5 #6 #7 #8 #9 #10 #11 NOTES: LDH 6" 6"* 6"* 7"* 9" 10" 11" 12"* 14"* TENSION LAP SPLICES - CLASS B - TOP & BOTTOM BARS (GRADE 60 UNCOATED BARS) NORMAL WEIGHT CONCRETE 'LD' TENSION DEVELOPMENT LENGTH (GRADE 60 UNCOATED BARS) NORMAL WEIGHT CONCRETE f'c = 3000 PSI f'c = 4000 PSI f'c = 5000 PSI f'c = 6000 PSI f'c = 8000 PSI f'c = 3000 PSI f'c = 4000 PSI f'c = 5000 PSI f'c = 6000 PSI f'c = 8000 PSI TOP BOTTOM TOP BOTTOM TOP BOTTOM TOP BOTTOM TOP BOTTOM LD TOP LD BOTTOM LD TOP LD BOTTOM LD TOP LD BOTTOM LD TOP LD BOTTOM LD TOP LD BOTTOM 28" 37" 47" 56" 81" 93" 105" 118" 131" 22" 29" 36" 43" 63" 72" 81" 91" 101" 24" 32" 40" 48" 70" 80" 91" 102" 113" 19" 25" 31" 37" 54" 62" 70" 79" 87" 22" 29" 36" 43" 63" 72" 81" 91" 101" 17" 22" 28" 33" 49" 55" 63" 70" 78" 20" 26" 33" 40" 58" 66" 74" 83" 93" 16" 20" 25" 31" 44" 51" 57" 64" 71" 17" 23" 29" 34" 50" 57" 64" 72" 80" 16" 18" 22" 26" 38" 44" 49" 56" 62" 22" 29" 36" 43" 63" 72" 81" 91" 101" 17" 22" 28" 33" 48" 55" 62" 70" 78" 19" 25" 31" 37" 54" 62" 70" 79" 87" 15" 19" 24" 29" 42" 48" 54" 61" 67" 17" 22" 28" 33" 49" 55" 63" 70" 78" 13" 17" 22" 26" 37" 43" 48" 54" 60" 15" 20" 25" 31" 44" 51" 57" 64" 71" 12" 16" 20" 24" 34" 39" 44" 49" 55" 13" 18" 22" 26" 38" 44" 49" 56" 62" 12" 14" 17" 20" 30" 34" 38" 43" 48" BAR SIZE #3 #4 #5 #6 #7 #8 #9 #10 #11 NOTES: 1. 2. 3. 4. 5. TABULATED VALUES ARE APPLICABLE ONLY IF CLEAR SPACING OF BARS BEING DEVELOPED OR SPLICED IS NOT LESS THAN 'db', CLEAR COVER IS NOT LESS THAN 'db', AND STIRRUPS OR TIES THROUGHOUT 'ld' IS NOT LESS THAN CODE MINIMUM OR CLEAR SPACING OF BARS BEING DEVELOPED OR SPLICED IS NOT LESS THAN 2X 'db' AND CLEAR COVER IS NOT LESS THAN 'db'. WHERE db IS THE NOMINAL DIAMETER OF THE BAR. 'TOP' BARS ARE HORIZONTAL REBAR WITH MORE THAN 12" OF FRESH CONCRETE CAST BELOW THE BARS AT THE END DEVELOPMENT LENGTH. FOR LIGHT WEIGHT CONCRETE, MULTIPLY THE TABULATED VALUES BY 1.3. FOR EPOXY COATED BARS, MULTIPLY TABULATED VALUES BY THE RATIO OF THE REINFORCEMENT YIELD STRENGTH DIVIDED BY 60 KSI. FOR CLASS "A" SPLICE USE VALUE AS NOTED IN THE TENSION DEVELOPMENT LENGTH TABLE. 1. 2. 3. 4. 5. TABULATED VALUES ARE APPLICABLE ONLY IF CLEAR COVER OF BARS BEING DEVELOPED OR SPLICED IS NOT LESS THAN 'db', AND STIRRUPS OR TIES THROUGHOUT 'LD' IS NOT LESS THAN CODE MINIMUM, OR CLEAR SPACING OF BARS BEING DEVELOPED OR SPLICED IS NOT LESS THAN 2X 'db' AND CLEAR COVER IS NOT LESS THAN 'db'. WHERE db IS THE NOMINAL DIAMETER OF THE BAR. 'TOP' BARS ARE HORIZONTAL REBAR WITH MORE THAN 12" OF FRESH CONCRETE CAST BELOW THE BARS AT THE DEVELOPMENT LENGTH. FOR LIGHT WEIGHT CONCRETE, MULTIPLY TABULATED VALUES BY 1.3. FOR EPOXY COATED BARS, MULTIPLY TABULATED VALUES BY 1.5 FOR BOTTOM BARS, AND BY 1.3 FOR TOP BARS. FOR REINFORCEMENT OTHER THAN GRADE 60, MODIFY THE TABULATED VALUES BY THE RATIO OF THE REINFORCEMENT YIELD STRENGTH DIVIDED BY 60 KSI. 'LDH' TENSION DEVELOPMENT LENGTH (EMBEDMENT LENGTH) FOR STANDARD END HOOKS (GRADE 60 UNCOATED BARS) NORMAL WEIGHT CONCRETE LDH 2" MIN. COVER (*) STANDARD 90° HOOK SIDE COVER > 2 1/2" 2" MIN. COVER ON EXPOSED SURFACES INCREASE ldh DIMENSION IF NECESSARY (*) STANDARD 180° HOOK SIDE COVER > 2 1/2" f'c=3000 PSI f'c=4000 PSI f'c=5000 PSI f'c=6000 PSI f'c=8000 PSI LDH LDH LDH LDH 6" 6"* 7" 8" 10" 11" 13" 14" 16" 12" 12" 14" 17" 20" 23" 25" 29" 32" BAR SIZE #3 #4 #5 #6 #7 #8 #9 #10 #11 BAR SIZE #3 #4 #5 #6 #7 #8 #9 #10 #11 6" 8" 10" 12" 14" 16" 18" 20" 22" LDC 9" 11" 14" 17" 20" 22" 25" 28" 31" 6" 7" 9" 10" 12" 14" 15" 17" 19" LDH 6" 6"* 8" 9" 11" 12" 14" 15" 17" 12" 15" 19" 23" 26" 30" 34" 38" 42" NOTES: 1. WHEN EITHER SIDE OR END COVER IS SMALLER THAN 2 1 2. 3. END CONCRETE COVER (90° HOOKS) ≥ 2". * FOR 180° HOOKS AT RIGHT ANGLES TO EXPOSED SURFACES, 2" MINIMUM COVER TO TAIL SHALL BE PROVIDED. 2", MULTIPLY "LDH" BY 1.4. 'LDC' COMPRESSION DEVELOPMENT LENGTH AND COMPRESSION LAP SPLICES (GRADE 60 UNCOATED BARS) NORMAL WEIGHT CONCRETE f'c ≥ 3000 PSI MINIMUM LAP SPLICE STANDARD LAP WITH COLUMN SPIRALS NOTES: 1. STANDARD LAP SPLICE LENGTH FOR COMPRESSION BARS = 30 BAR DIAMETERS, BUT NOT LESS THAN 12". 2. WHEN BARS OF DIFFERENT SIZE ARE LAP SPLICED, SPLICE LENGTH SHALL BE THE LARGER OF LDC. SPIRALS SHALL CONFORM TO ACI 7.10.4 & 10.9.3. 3. 10/16/2021 FIRM NO. 17948 REMOVE EXISTING SOIL 2'-0" BEYOND BUILDING OUTLINE - REPLACE WITH SLOPED COMPACTED FILL & 9" MAX. OF TOP SOIL FOR BEAM DEPTHS ≥ 2'-6" PROVIDE #4 CONT. @ EA. FACE @ 12" O.C. (2) #5 CONT. TOP & BOTTOM W/ #3 STIRRUPS @ 24" O.C. TO APPROVED BEARING: 18" BELOW EXISTING GRADE #4 CONT. HORIZ. REMOVE EXISTING SOIL 2'-0" BEYOND BUILDING OUTLINE - REPLACE WITH SLOPED COMPACTED FILL & 9" MAX. OF TOP SOIL FOR BEAM DEPTHS ≥ 2'-6" PROVIDE #4 CONT. @ EA. FACE @ 12" O.C. (2) #5 CONT. TOP & BOTTOM W/ #3 STIRRUPS @ 24" O.C. TO APPROVED BEARING: 18" BELOW EXISTING GRADE 1'-0" 3 1/2" Y F I R E V 1'-0" #3 @ 16" O.C. EA. WAY @ MID-DEPTH OF SLAB, TYP. 4 1/2" 10 MIL VAPOR RETARDER, TYP. " 0 - ' 2 . I N M COMPACTED SELECT FILL, TYP. REMOVE EXISTING SOIL 2'-0" BEYOND BUILDING OUTLINE - REPLACE WITH SLOPED COMPACTED FILL & 9" MAX. OF TOP SOIL FOR BEAM DEPTHS ≥ 2'-6" PROVIDE #4 CONT. @ EA. FACE @ 12" O.C. (2) #5 CONT. TOP & BOTTOM W/ #3 STIRRUPS @ 24" O.C. TO APPROVED BEARING: 18" BELOW EXISTING GRADE #3 @ 16" O.C. EA. WAY @ MID-DEPTH OF SLAB, TYP. 4 1/2" 10 MIL VAPOR RETARDER, TYP. " 0 - ' 2 . I N M COMPACTED SELECT FILL, TYP. 4 1/2" (2) #5 CONT. TOP & BOTTOM W/ #3 STIRRUPS @ 24" O.C. #3 @ 16" O.C. EA. WAY @ MID-DEPTH OF SLAB, TYP. 10 MIL VAPOR RETARDER, TYP. " 0 - ' 2 COMPACTED SELECT FILL, TYP. #3 @ 16" O.C. EA. WAY @ MID-DEPTH OF SLAB, TYP. 4 1/2" (2) #5 CONT. TOP & BOTTOM W/ #3 STIRRUPS @ 24" O.C. 1'-0" NOTE: SEE PLAN FOR DROP LOCATION. N A L P E E S 10 MIL VAPOR RETARDER, TYP. " 0 - ' 2 COMPACTED SELECT FILL, TYP. 1'-0" 1 TYP. PERIMETER GRADE BEAM 3 / 4" = 1' - 0" 2 TYP. PERIMETER GRADE BEAM 3 / 4" = 1' - 0" 3 TYP. INTERIOR GRADE BEAM 3 / 4" = 1' - 0" 4 INTERIOR GRADE BEAM W/ DROP 3 / 4" = 1' - 0" 1'-0" VERIFY . I N M " 2 / 1 1 1'-0" #3 VERT. @ 24" O.C. #3 @ 16" O.C. EA. WAY @ MID-DEPTH OF SLAB, TYP. 4 1/2" 10 MIL VAPOR RETARDER, TYP. " 0 - ' 2 . I N M COMPACTED SELECT FILL, TYP. FOR BEAM DEPTHS ≥ 2'-6" PROVIDE #4 CONT. @ EA. FACE @ 12" O.C. (2) #5 CONT. TOP & BOTTOM W/ #3 STIRRUPS @ 24" O.C. TO APPROVED BEARING: 18" BELOW EXISTING GRADE #3 @ 16" O.C. EA. WAY @ MID-DEPTH OF SLAB, TYP. 4 1/2" 10 MIL VAPOR RETARDER, TYP. " 0 - ' 2 . I N M COMPACTED SELECT FILL, TYP. #3 @ 16" O.C. EA. WAY @ MID-DEPTH OF SLAB, TYP. 4 1/2" 10 MIL POLY VAPOR BARRIER, TYP. COMPACTED SELECT FILL, TYP. 1'-0" MIN. . I N M " 2 / 1 1 4 1/2" 5 TYP. PERIMETER GRADE BEAM @ GARAGE 3 / 4" = 1' - 0" 6 3 / 4" = 1' - 0" TYP. PERIMETER GRADE BEAM @ GARAGE DOOR 7 SLAB DROP DETAIL 3 / 4" = 1' - 0" 10/16/2021 FIRM NO. 17948 SEE SHEET S0.0 FOR ADDITIONAL ANCHOR REQUIREMENTS STANDARD WASHER AND NUT (SNUG-TIGHT) 1 2" Ø "J" BOLT W/ MIN. EMBEDMENT INTO CONCRETE AS SHOWN 1 F 3 O R / O 4 F C M " O M E I N D N C G . R E E T E 7 " M I N . OPTION: 1 2" Ø X 4 1 4" EMBED SIMPSON TITEN HD ANCHOR 16d NAILS @ 12" O.C. 8d NAILS @ 6" O.C. (ALL PANEL EDGES) 8d NAILS @ 12" O.C. ON ALL FRAMING MEMBERS NOT AT PANEL EDGES ORIENTATION OF STUD MAY VARY - SEE DETAIL 3/S4.0 16d NAILS @ 12" O.C. ORIENTATION OF STUD MAY VARY - SEE DETAIL 3/S4.0 GYPSUM WALL BOARD INSTALLED IN ACCORDANCE W/ CHAPTER 7 OF IRC WOOD STRUCTURAL PANEL INSTALLED IN ACCORDANCE W/ SHEET S0.0 GYPSUM WALL BOARD INSTALLED IN ACCORDANCE W/ CHAPTER 7 OF IRC WOOD STRUCTURAL PANEL INSTALLED IN ACCORDANCE W/ SHEET S0.0 8d NAILS @ 6" O.C. ALL FRAMING MEMBERS AT PANEL EDGES & 12" O.C. ON ALL FRAMING MEMBERS @ PANEL EDGES OUTSIDE CORNER DETAIL INSIDE CORNER DETAIL SPLICE LENGTH PER SCHEDULE SPLICE OVER 2X DOUBLE TOP PLATE NAILS BETWEEN SPLICE LOCATION PER SCHEDULE - STAGGERED LENGTH OF PLATE (BETWEEN PERP. WALL) SPLICE LENGTH MINIMUM NAIL ALONG SPLICE LENGTH OVER 30'-0" BETWEEN 20'-0" & 30'-0" LESS THAN 20'-0" 4'-0' 2'-8' 1'-4' 27-16d 18-16d 10-16d NOTE: 1. DO NOT SPLICE TOP PLATES WITHIN 6'-0" OF ENDS OF TIMBER SHEAR WALLS. THIS DETAIL APPLIES AT ALL WALLS. 2. 1 TYPICAL SILL PLATE TO CONCRETE ATTACHMENT 1 " = 1 ' - 0 " 2 1 " = 1 ' - 0 " TYPICAL EXTERIOR CORNER FRAMING FOR CONTINUOUS PANEL SHEATHING CORNER AND PARTITION POSTS DETAIL 3 1 1 / 2" = 1' - 0" 4 TYPICAL TOP PLATE SPLICE DETAIL 1 " = 1 ' - 0 " 3 1/2" 5 1/2" SCHEDULED MEMBERS - SEE PLAN 2-PLY 3-PLY 3" 2'-8" . X A M " 2 Q E Q E . X A M " 2 1'-4" SECTION GANGNAIL EA. 2X W/ (1) 20d @ 32" O.C. MAX TOP & BOTTOM, TYP. 1 2" PLYWOOD FILLER, TYP. BETWEEN 2X MEMBERS, TYP. BEAM/HDR - SEE PLAN STAGGER TOP & BOTTOM ROWS OF NAILS (3) ADD'L 20d (EA. SIDE @ 6X FRAMING) TYP, EA. END OF BUILT-UP MEMBER N 5 O 0 T % C O H F G T R H E A E T P E L R A T T E H W A N I D T H EXTERIOR OR BEARING WALL TOP PLATES 16 GAGE (0.054") AND 1.5" WIDE METAL TIE FASTENED ACROSS AND TO THE PLATE @ EA. SIDE OF THE NOTCH W/ (8) 16d NAILS EA. SIDE PIPE BY OTHERS 6 / D . X A M L/3 L/3 3 / D . X A M L/3 L L/3 4 / D . X A M D/3 MAX. NO NOTCHES PERMITTED NO NOTCHES PERMITTED D D/3 MAX. D 6 / D . X A M MAX. D FROM SUPPORT FLOOR JOIST - CENTER CUTS RAFTER/CEILING JOISTS L/3 L/3 4 / D . X A M D 2 T " O O M F P J & I N . F B O I S T O R O T D / 3 M A X . T M O M L A U T C A ( D ) H T P E D PIPE OR CONDUIT L L NO NOTCHES PERMITTED FLOOR JOIST - END CUTS 6 TYPICAL BUILT UP MEMBER NAILING 1 " = 1 ' - 0 " TOP PLATE FRAMING TO ACCOMMODATE PIPING 7 1 1 / 2" = 1' - 0" 8 CUTTING, NOTCHING AND DRILLING DETAIL 1 " = 1 ' - 0 " WOOD HEADER OR BEAM - SEE PLAN KING STUD - SEE SCHEDULE BEARING STUD - SEE SCHEDULE MULTI-STUD COLUMN SCHEDULE COLUMN # KING STUDS # BEARING STUDS 2-STUD 3-STUD 4-STUD 5-STUD 1 1 2 2 1 2 3 4 NOTE: SEE STRUCTURAL NOTES SHEET 0.0 FOR NAILING. 5 TYPICAL MULTI-STUD COLUMN DETAIL 1 1 / 2" = 1' - 0" TOP PLATES 5/8" MIN. TO EDGE BORED HOLE MAX. DIAMETER 40% OF STUD DEPTH N STU OTCH M EXCEED 25% OF D DEPTH UST N OT 2X STUD FRAMING 5/8" MIN. TO EDGE IF HOLE IS BETWEEN 40% AND 60% OF STUD DEPTH, THEN STUD MUST BE DOUBLE AND NO MORE THAN TWO SUCCESSIVE STUDS ARE DOUBLED AND SO BORED BORED HOLES SHALL NOT BE LOCATED IN THE SAME CROSS SECTION OF CUT OR NOTCH IN STUD 2X BOTTOM PLATE TOP PLATES 5/8" MIN. TO EDGE BORED HOLE MAX. DIAMETER 60% OF STUD DEPTH N STU OTCH M EXCEED 40% OF D DEPTH UST N OT 2X STUD FRAMING 5/8" MIN. TO EDGE 2X BOTTOM PLATE BORED HOLES SHALL NOT BE LOCATED IN THE SAME CROSS SECTION OF CUT OR NOTCH IN STUD NOTCHING & BORED HOLE LIMITATIONS FOR EXTERIOR WALLS & BEARING WALLS 9 3 / 4 " = 1 ' - 0 " NOTCHING & BORED HOLE LIMITATIONS FOR INTERIOR NON-BEARING WALLS 10 3 / 4 " = 1 ' - 0 " 10/16/2021 FIRM NO. 17948 ROOF RAFTERS SEE PLAN PANEL EDGE NAILING PROVIDE 2X BLOCKING @ PANEL EDGE - CENTER @ JOINT SILL ANCHORS - SEE SHEARWALL SCHEDULE 2X BLOCKING IN BETWEEN RAFTERS ROOF DECKING - SEE S0.0 FOR THICKNESS & ATTACHMENT H2.5A HURRICANE TIE @ EVERY RAFTER ROOF TRUSSES, TYP - SEE PLAN GALBE END TRUSS W/A35 CLIPS - SEE SHEARWALL SCHEDULE FOR SPACING EDGE NAILING 15 32" PLYWOOD SHEATHING 2X STUD WALL 2 EAVE WALL DETAIL 1 " = 1 ' - 0 " 3 GABLE END TRUSS OVER SHEAR WALL 1" = 1' - 0" ROOF DECKING - SEE S0.0 FOR THICKNESS & ATTACHMENT T.O. DBL PLATE SEE PLAN ROOF TRUSS - SEE PLAN PANEL INTERIOR FASTENERS - SEE SHEAR WALL SCHEDULE PLYWOOD SHEATHING - 2X STUDS WALL PANEL EDGE T.O. DECK SEE PLAN 1 TYPICAL SHEATHING ATTACHMENT - ALL EXTERIOR WALLS & INTERIOR SHEAR WALLS SHEARWALL FRAMING NOTES 3 / 4 " = 1 ' - 0 " SEE LATERAL BRACING PLAN FOR LOCATION OF SHEATHED WALLS. PLYWOOD MAY BE INSTALLED LONG SIDE HORIZONTAL OR VERTICAL AND PANELS MUST BE STAGGERED. PANEL EDGE NAILING IS REQUIRED AT ALL HOLDDOWN POST AND AT EACH STUD USED IN BUILT-UP HOLDDOWN POSTS. 1. 2. 3. 4. MINIMUM EDGE DISTANCE FOR NAILS SHALL BE 3 5. WHERE SHEATHING IS APPLIED TO BOTH SIDES OF WALL, PANEL EDGE JOINTS SHALL BE OFFSET. 6. USE PRESSURE TREATED 2X SILL PLATE FOR ALL SHEAR WALLS BEARING DIRECTLY ON CONCRETE OR MASONRY. 7. USE COMMON NAILS ONLY (BOX NAILS ARE NOT PERMITTED) 8. WHERE WALL PIER IS 5'-0" WIDE OR LESS, MAXIMUM SILL PLATE ANCHOR BOLT SPACING SHALL BE 18" O.C. 8". 10/16/2021 FIRM NO. 17948