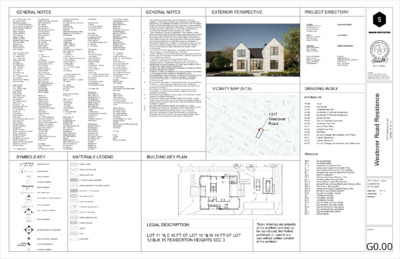

C.5 - 1317 Westover Rd - Full set of plans submitted by applicant — original pdf

Backup