Revised Proposed Draft Amendments — original pdf

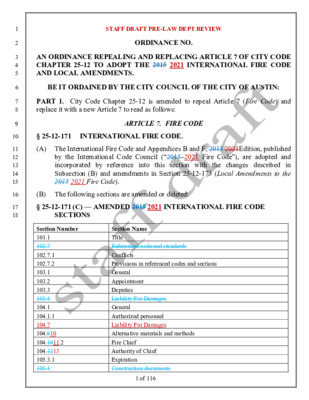

Backup