13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 9 - Public Comment 3 — original pdf

Backup

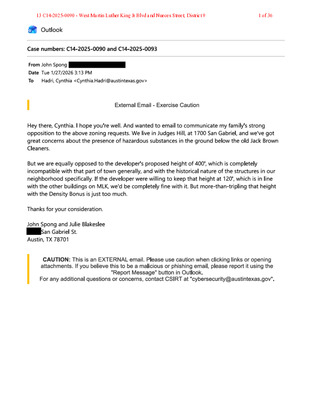

13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 91 of 36 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 92 of 36 Eagle Synergistic Optimizing Technologies, LLC Specialized in High Resolution Site Characterization Caroline Reynolds CR Solutions crsolns@icloud.com 512-454-8880 Caroline, Thank you for requesting a proposal for subsurface imaging High Resolution Site Characterization (HRSC) services in Austin, TX. Please find attached Eagle Synergistic’s proposal to help meet your project objectives by optimizing the investigative phase with high-resolution data. We strive to ensure that our client’s goals are not only met but also exceeded. Please let us know if you have any questions or revision requests. Thank you, Janet L Castle, PG, President jcastle@EagleSynergistic.com Eagle Synergistic 751 Pine Ridge Rd #100 Golden, CO 80403 Direct: 720-475-0022 Office: 303-305-7783 www.EagleSynergistic.com Locations Nationwide: CO, TX, CA, GA, PA, IL WOS O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 93 of 36 Proposal # 23.109 CR Solutions JACK BROWN CLEANERS 615 W. MLK, JR. BLVD AUSTIN, TEXAS O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 94 of 36 Table of Contents OVERVIEW .................................................................................................................................................................... 4 Site Description per Client .......................................................................................................................................... 4 SITE FIGURES .............................................................................................................................................................. 5 PROPOSED POINTS .................................................................................................................................................... 9 TECHNICAL APPROACH AND SCOPE OF WORK .................................................................................................... 10 Scope of Work .......................................................................................................................................................... 10 Site Safety ................................................................................................................................................................ 12 Experience and Past Performance ........................................................................................................................... 12 Capacity to Perform the SOW .................................................................................................................................. 13 HRSC TECHNOLOGY ................................................................................................................................................. 14 Membrane Interface Probe ....................................................................................................................................... 14 CONFIRMATION & CORRELATION (OPTIONAL) ...................................................................................................... 19 1.75” Ground Water Sampler.................................................................................................................................... 19 Project Assumptions ................................................................................................................................................. 20 Insurance .................................................................................................................................................................. 21 Health & Safety Audit and Risk Management Programs .......................................................................................... 21 CLIENT DELIVERABLES AND EXAMPLES ................................................................................................................ 22 3D Modeling and Visualizations................................................................................................................................ 25 Numerous models and views will be supplied as part of the 3D package ................................................................ 27 OTHER HRSC SERVICES .......................................................................................................................................... 28 PRICING ...................................................................................................................................................................... 31 SIGNATURE PAGE ..................................................................................................................................................... 33 THANK YOU ................................................................................................................................................................ 34 O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 95 of 36 P a g e | 4 OVERVIEW Eagle Synergistic Optimizing Technologies, LLC is pleased to submit this proposal for High Resolution Site Characterization Subsurface Imaging services to support CR Solutions in achieving your goals. Eagle Synergistic’s team has over 40 years combined experience in geological, geophysical, logging, subsurface imaging, and 3D modeling aspects. Our business model includes a critical upgrade of the current norms in the HRSC environmental investigation and remediation industry. Eagle Synergistic solely specializes in HRSC subsurface imaging technology and modeling. In support of our unique business model, our team of HRSC field specialists, project managers, and 3D modelers are technically proficient and specialized in subsurface imaging. Site Description per Client • Site History o Site is a former dry cleaner. o Site history will be provided at a later date. • Topography/Terrain o This investigation will take place on asphalt and pavement. o Potholing and/or concrete coring requirements will be determined later. • Groundwater o Groundwater elevation on site varies between 5’ to 15’ bgs per client information. Groundwater gradient is to the east per client data. • Lithology o Cross-section A-A' (Figure 4C-1, WEM, 2009a) (provided client) depicts site geology along an east- west line. In cross-section A-A', the upper-most "clay" unit (Eagle Ford Formation, see Item A.1 and Item A.2) is observed to change in thickness significantly between monitoring wells MW-2 (and MW-10) and MW-4. • Contaminants of Concern o CoCs are chlorinated solvents ▪ PCE, TCE, cis-1,2-DCE, and VC • Site Access o No site access issues appear to be present. o Exclusion zones will be set up around on site field operations. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 96 of 36 SITE FIGURES P a g e | 5 O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 97 of 36 P a g e | 6 O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 98 of 36 P a g e | 7 O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 99 of 36 P a g e | 8 O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 910 of 36 PROPOSED POINTS P a g e | 9 Initial points are based on potential source area(s) and/or discussions with client. Proposed points are subject to change due to dynamic decision making in the field based on live HRSC data. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 911 of 36 P a g e | 10 TECHNICAL APPROACH AND SCOPE OF WORK Technical Approach Eagle Synergistic will supply a team of HRSC specialists and a command center vehicle, which will house all applicable technologies and equipment. Eagle Synergistic command center vehicles will come equipped with multiple backup probes, trunklines and replacement parts. Two probes, trunklines and tool strings will be prepared at all times, allowing for efficient equipment changes. Subsurface imaging will begin using the membrane interface probe (MIP) coupled with an electrical conductivity dipole (EC) and a hydraulic profiling tool (HPT) system, collectively known as the MIHPT. This probe is a logging tool that indicates volatile hydrocarbon and solvent contamination in addition to soil electrical conductance and indicators of formation permeability. An inert carrier gas is continually swept behind a heated membrane in the probe, delivering diffused VOC’s to a series of detectors at the surface. The detectors each respond to different analyte properties, which allow Eagle Synergistic specialists to discern the contaminant to its family group, as well as provide the ability to map out the contaminant plume from source to extent. Obtaining an understanding of lithological and hydrogeological data, along with the contaminant information, allows us to determine if contamination is near to prominent migration pathways or bound up in a storage zone. Eagle Synergistic exceeds Geoprobe's guidelines and SOPs for quality control before and after every boring. For the MIHPT, we will perform response tests using a site-specific contaminant with a range of concentrations to demonstrate detector, probe, and trunkline effectiveness and accuracy. Additionally, we will test the EC sensor using a current resistor with known high and low values. The HPT sensor and screen are tested using the HPT reference tube which confirms the sensors ability to accurately measure pressure differentials. These tests can be printed out and are available as part of the final data package if requested. Eagle Synergistic Optimizing Technologies plans to work with a reputable and approved direct push provider. The DPT Provider will be responsible for advancing Eagle Synergistic’s subsurface imaging probes, as well as for confirmation sampling. Scope of Work Eagle Synergistic will mobilize to Austin, TX from our location in Austin. Eagle Synergistic specialists will perform QC checks on all equipment prior to the project start date to ensure that applicable equipment is ready for advancement. We will begin using our MIHPT system at predetermined locations. Subsequent HRSC borings will be placed at planned locations, or at a new location based on real-time HRSC data. This dissolved phase contamination, lithology, and hydraulic conductivity data can be instantly utilized by field personnel in order to determine the next boring locations. This approach to HRSC investigations allows a high level of dynamic decision making, leading to the most efficient characterization of the site. • Proposed approximately 15 MIHPT borings to 20’ bgs. • Proposed scope will take approximately 3 days of onsite operations. • Client goals are to investigate near MW-6 and delineate the southeastern side of the site. • Our first borings will be near the MW-6 as identified by client’s previous groundwater and soil sampling data. • Client will work with HRSC team to dynamically make decisions on subsequent HRSC borings to assist with delineating the plume and/or source. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 912 of 36 P a g e | 11 • MIHPT borings placement will be determined based on the historical data per client and dynamic decision making between client and Eagle Synergistic. • Client will notify Eagle Synergistic if potholing and/or concrete coring will be required for each boring. • Eagle Synergistic will collect GPS coordinates for HRSC borings only if requested by client. • If applicable, Eagle Synergistic will work with client and DPT Provider to select discrete, confirmatory soil and/or groundwater sample locations and intervals. Lab analytical data is handled entirely via the client. Eagle Synergistic anticipates that we will have the ability to complete approximately 150-200 feet of MIP borings per day. These estimations are lithology and site dependent. This also assumes that weather conditions and other factors are favorable. Eagle Synergistic’s goal is to assist in understanding the HRSC data gathered. Our field specialists will work with field scientists to understand the live data as it is acquired. We will also be working virtually with CR Solutions to assist with interpretation and making important decisions regarding the placement of further points. Our clients not only receive consistent daily communication, but also receive detailed daily reports. This report will include all preliminary data, including footage, field notes, boring locations completed, and individual logs. Final logs and a comprehensive report, which will include overlays and cross section views, will be provided after project completion. After receiving the final comprehensive report, our technical team will contact you to discuss and/or present the HRSC data. If 3D modeling is requested, Eagle Synergistic will begin processing the data once HRSC activities are completed. We are always available to answer any questions that may arise. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 913 of 36 P a g e | 12 Site Safety Our number one priority is the safety of our personnel and the safety of others. If requested, Eagle Synergistic will develop a site-specific health and safety plan (HASP) before the scheduled start of the project. CR Solutions and/or DPT Provider are responsible for obtaining and verifying utility locates. Eagle Synergistic may request copies of locates from CR Solutions and DPT Provider. All Eagle Synergistic employees assigned to the project will be thoroughly informed regarding the scope of work and site-specific hazards. Daily tailgate meetings will be held to discuss and inform all personnel of job-related hazards. If applicable, the finalized HASP will be sent to CR Solutions for approval upon request. Thorough SOP’s for the safe use of HRSC technologies have been developed, and all field personnel have been trained on their use. Copies of these SOP’s are in all field vehicles for employee reference. SDS’s for all utilized chemicals are also located in field vehicles, and Eagle Synergistic personnel will be thoroughly trained on the health risks of contaminants specific to the site prior to the commencement of work. Our employees receive regular, industry-leading safety trainings. Without exception, all employees have up-to-date HAZWOPER 40-hour certifications. Red Cross First Aid, CPR, Basic Safety Plus, and site- specific safety trainings have been completed by key HRSC specialists. Eagle Synergistic also conducts in-house monthly safety training meetings. At a minimum, Eagle Synergistic employees are always required to wear Level D PPE on-site. Eagle Synergistic field employees are trained on the proper use of PPE and these items are regularly inspected to ensure that they are in good condition. PPE can be added for sites requiring greater protection than Level D. On sites requiring the use of respirators, all field employees will have active respirator fit tests. Eagle Synergistic participates in and complies with safety and risk management programs such as Avetta® and ISN® Networld. All employees are randomly tested under the DISA program. Copies of all Eagle Synergistic safety documents and programs are available to our clients upon request. Experience and Past Performance Eagle Synergistic leverages our combined 40 years of geologic and investigative experiences to successfully address our client’s goals. Our team has a proven track record of high-quality data, detailed analysis, and rapid turnaround times for our reports. Our HRSC systems have been used to investigate numerous federal, state, and locally funded projects and our top-tier data has been used in numerous, high- profile decisions. Our specialized team includes degreed geologists, geophysicists, petrophysicists, biologists, environmental scientists, and more. Our team has performed HRSC activities on various restrictive sites requiring extra care and regulation, such as oil refineries, national parks, government and military facilities, superfund sites, and high-tech manufacturing facilities. In addition to our specialized field services, Eagle Synergistic is also highly experienced in 3D modeling and visualization, enabling our clients to develop a more accurate CSM going into the remediation phase. Eagle Synergistic is extremely familiar with Chlorinated sites and regulations, as they are one of the principal areas in which we serve. We have worked closely with the Chlorinated regulators of many organizations. Senior leadership within our company has been asked to give keynote speeches regarding the effectiveness of HRSC at Chlorinated sites to multiple groups of regulators. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 914 of 36 P a g e | 13 Capacity to Perform the SOW Eagle Synergistic Optimizing Technologies, LLC is a leading national provider of HRSC and subsurface imaging services. Eagle Synergistic was founded to provide a critical upgrade to the HRSC industry, where we focus solely on subsurface investigative work. We have built a team of HRSC specialists who are technically proficient, passionate, and focused on the work they are performing. Our team of HRSC specialists are thoroughly trained and certified with the HRSC manufacturer. These certifications include MIP, OIP, HPT, Low-Level MIP, and Groundwater Sampling Profiler analysis. Our HRSC Command Center vehicles stationed nationwide contain the equipment necessary to perform an array of subsurface imaging. These covered, climate-controlled vans function as mobile offices for our field teams and clients. Large TV displays allow our clients in the field to observe real-time data as the probes are advanced into the subsurface. Wi-Fi and satellite connectivity can allow us to upload this data to our clients from anywhere in the world. With this unique business model, clients can make real time decisions. In addition to containing the electronics necessary to run our detector arrays, HRSC Command Center vans also include pre-strung rods with the probes attached and ready to go. Two systems are always strung up to increase efficiency. The self-contained HRSC Command Center vehicles are also equipped with backup parts and tools enabling our specialists to perform necessary replacements and repairs. This business model is a significant enhancement, not the norm in the industry, and helps ensure that your project stays efficient. Eagle Synergistic does not have a mixed business model, allowing us to remain the technical experts in the field of HRSC. Pursuing this unique business model, Eagle Synergistic teams up with reputable local DPT operators. This can lead to decreased mobilization cost. Eagle Synergistic will provide probe rods and all applicable Geoprobe attachments required to push HRSC tooling. Our probes are advanced using a preferred Geoprobe 6600 or larger machine. An equivalent AMS Power Probe or CPT rig is also acceptable. We have numerous DPT partners across the country and, if requested, will assist in coordinating the proper equipment. Once HRSC operations have begun, our virtual project managers will be in close contact with the client and our field team. We will be actively engaged to facilitate dynamic decision making, and to ensure that you understand the data as your goals are being met. If a 3D visualization is requested, our in-house 3D modeling experts will complete extensive modeling and reports which can further enhance your CSM. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 915 of 36 P a g e | 14 HRSC TECHNOLOGY Membrane Interface Probe Membrane Interface Probe (MIP): A system manufactured by Geoprobe Systems® for the detection and measurement of volatile organic compounds (VOCs) in the subsurface. A heated probe carrying a semi-permeable membrane is advanced to depth in the soil. VOCs in the subsurface diffuse across the membrane, enter a carrier gas stream, and are swept to gas phase detectors within the HRSC Command Centers for measurement. MIP Principles of Operation The MIP is a screening tool with semiquantitative capabilities acting as an interface between volatile contaminates at depth in the soil and gas phase detectors at the surface. The MIP membrane is semipermeable and is comprised of a thin film polymer impregnated into a stainless steel screen for support. The membrane is approximately 6.35mm in diameter and can be easily replaced. The membrane is placed in a heated block attached to the probe. This block is heated to approximately 100-120 degrees Celsius as the probe is advanced into the soil. Heating the block accelerates analyte diffusion across the membrane while at the same time minimizing membrane absorption. Diffusion across the membrane is driven by the concentration gradient between the contaminated soil and the clean carrier gas behind the membrane. A constant gas flow of 35-45 mL/min sweeps behind the membrane and carries the contaminants to the gas phase detectors at the surface. Travel time from the membrane interface to the detector(s) is approximately 30-60sec (depending on the length of trunkline and flow rate). O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 916 of 36 Detector Array P a g e | 15 Our MIP detector system utilizes three detectors: an XSD (halogen specific detector, A), FID (flame ionization detector, B), and a PID (photoionization detector, C). Each of these detectors respond to different traits of an analyte and the combination of all three provides the investigator with the ability to discern between typical contaminant types such as hydrocarbons and chlorinated solvents, even when comingled. Halogen Specific Detector (XSD) The XSD operates in an oxidative state that converts halogenated organics into free halogen atoms. These halogen (X) atoms are adsorbed onto the activated platinum surface of the detector probe assembly resulting in an increase thermionic emission. This emission current is comprised of free electrons, and negative and positive ions which provide a corresponding voltage that is measured via an electrometer circuit in the detector controller. The XSD is a destructive detector used for the detection of total halogenated VOCs in the MIP system. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 917 of 36 P a g e | 16 Flame Ionization Detector (FID) The FID uses a hydrogen/air flame to produce ions and electrons that can conduct electricity through the flame. A potential is applied across the burner tip and the collector electrode. The resulting current is then amplified and recorded. The FID will respond to any VOCs at a high enough concentration. The FID has a lower sensitivity to common VOC analytes than other detectors and typically serves as a confirmation detector run in tandem with the PID and XSD however it is the primary detector for mapping methane impacts since it does not show up on the other detectors. Photo Ionization Detector (PID) The PID uses ultraviolet radiation to ionize molecules in the effluent of the MIP carrier gas stream for analyte detection. The PID is a non-destructive detector and can therefore be used in series with other detector types. For a compound to be detected by a PID the chemical must have an ionization potential below the electron voltage of the PID lamp. The most common PID lamp used with the MIP is 10.6eV. The PID is generally used for detection of aromatic hydrocarbons such as benzene and toluene and double bonded chlorinated compounds such as trichloroethylene and perchloroethylene. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 918 of 36 P a g e | 17 EC Principles of Operation The electrical conductivity measurement is accomplished by using a dipole measurement arrangement at the end of the MIP and the OIP probe. The field instrument induces a current across the electrical dipole and probe shell as it penetrates the soil. The system measures electrical current and voltage and from these parameters can calculate electrical conductivity. Higher electrical conductivity is typically representative of finer grained sediments, such as silts and clays, while sands have distinctively lower conductivities. Ionic contaminants in the soil or pore fluids will increase the measured conductivity. This enables mapping of salt and brine contaminant plumes. Interpretation of electrical conductivity (EC) logs comes with field experience. It is very important that soil core samples are taken to confirm lithologic changes as each EC log is unique per site. As a generalization, a high conductivity reading indicates a smaller grain size, and a low conductivity reading indicates a larger grain size When possible, it is recommended to run the EC in conjunction with the HPT. In general, both detectors should trend together, confirming the collected lithological and hydrogeological data. An additional benefit of running both detectors together is that if one of the two is rendered ineffective due to site-specific geological conditions the other detector can still be used to gain valuable subsurface information. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 919 of 36 P a g e | 18 HPT Principles of Operation In the HPT system, water from a supply tank (A) is pumped by the HPT controller (B) at a set flow rate through the trunkline (D) and into the formation after passing through the injection screen (F). Measurement of the injection pressure in the HPT system is made using a downhole pressure transducer (E). Use of a transducer in the downhole position allows measurement of the injection pressure at the HPT screen only and excludes frictional the HPT losses through the trunkline. The downhole transducer position is also necessary for making hydrostatic pressure measurements at the probe. The HPT system can: flow tube of • Produce a detailed log of relative formation permeability • Be used to estimate hydraulic conductivity in the saturated zone • Logs HPT injection pressure, flow rate and electrical conductivity • Use pressure dissipation tests to measure hydrostatic pressure • Determine piezometric profile and water table depth EC (Grain Size Indicator) HPT Pressure HPT Line Pressure HPT Flow Abs. Piez. Pressure Tight clay interval Sandy interval Silty sands High permeability Groundwater table Dissipation test High transmissivity zones Est. K The HPT system adds the following datasets, from left to right: electrical conductivity, HPT pressure, HPT line pressure, HPT flow, absolute piezometric pressure and estimated K values. The HRSC signatures are helpful indicators for contaminants, lithology, and hydrogeological properties. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 920 of 36 P a g e | 19 CONFIRMATION & CORRELATION (OPTIONAL) Pending client discussion, Eagle Synergistic recommends collection of physical confirmation soil and/or ground water samples from 10-20% of HRSC borings. High resolution sampling at numerous borings enhances the ability to make the HRSC data semi-quantitative. At each offset boring, our HRSC Specialists will make recommendations for vertical, high resolution, physical sampling, correlated with HRSC signatures. If desired, discrete groundwater sampling can be performed using the Discrete Groundwater Sampling Profiler, Groundwater Sampler, or the Screen Point 16 Groundwater Sampler (SP16) probe. 1.75” Ground Water Sampler This tool utilizes 1.75” rods to advance the probe into the subsurface. Attached to the probe are two .25” water lines, (specialized tubing for PFAS sites). One tubing line is an injection line providing a consistent flow of DI water in order to provide the HPT data. The other line is a sample line which has a mechanical bladder pump attached to it that will pump the discrete water samples to the surface. DI water is then utilized to purge the sample line before advancing further to obtain additional samples. Specific conductance meters are utilized to confirm formation water or DI water. In addition to sample collection, this tool has the ability to: • Produce a detailed log of relative formation permeability • Log HPT injection pressure, and flow rate HPT Pressure HPT Flow Low permeability, resulting in low yields -High permeability -Within groundwater table -Resulting in high yields O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 921 of 36 Project Assumptions P a g e | 20 All affiliated parties on site will abide by established safety protocols. • • Work can be completed during daylight working hours, unless otherwise specified. • • • • • • • • • • • • • • • • • • • • • Eagle Synergistic will directly contract the DPT provider specifically for advancing HRSC tooling; and will assist with communications and logistics. Eagle Synergistic will directly contact the DPT provider for necessary materials and ancillary items only within the attached/included quote. All necessary permits and licenses will be completed by client and/or DPT provider, unless specified for Eagle Synergistic. If necessary, traffic control will be organized with surrounding businesses and provided by DPT provider or client. Utility locates will be completed and verified by DPT provider and/or client prior to work beginning on site. DPT providers are able to push Eagle Synergistic’s HRSC probes to depth. Additional hours/charges may apply due to refusal or slower penetration rates. Eagle Synergistic will not be held responsible for any damage or liabilities caused by other subcontractors, including DPT providers. Eagle Synergistic will not be held responsible for normal impact to terrain, landscaping, etc., resulting from the track rig or the HRSC Command Center Units. Eagle Synergistic will take dissipation tests with client’s approval at recommended depths, when feasible, to calculate estimated K values. Individual sensors are not prorated. Running systems with or without the integrated HPT port, when applicable, does not affect pricing. Running systems with or without the EC, when applicable, does not affect pricing. Eagle Synergistic will provide ancillary items related to HRSC tools that the DPT operator will use during probe advancement and retrieval. DPT provider will follow state and site standards for drilling, coring, borehole abandonment, decontamination, and more. All applicable supplies and rentals will be handled by the DPT provider and/or the client. DPT Provider and clients will be responsible for all utility locates and any issues that arise from locates and utilities. Eagle Synergistic will direct DPT operator on the rate of push. Eagle Synergistic will decontaminate rods, if requested. Decontamination in between each boring will decrease production rates. If the lithological conditions encountered become potentially damaging to the probes and/or tool string, the HRSC operator will call refusal. Should the client insist that Eagle Synergistic continues the boring, the client will be held responsible for applicable tool damage or loss. If tooling is stuck or loss, retrieval of tools is a priority within the scope of the project. Due to the nature of this technology, and the process of hammering sensitive equipment into varying lithology, some downtime is expected. Downtime is accounted for within Eagle Synergistic’s HRSC day rate. If refusal is hit early due to lithology, Eagle Synergistic’s HRSC day rates still apply. • • • While Eagle Synergistic may make suggestions regarding confirmation sampling, the client will be solely responsible for • • • • • the collection, storage, and transportation of any samples. All costs associated with lab and sampling are the responsibility of the client. Eagle Synergistic holds the ability to charge a standby rate for delays to the project due to client, other parties, weather, or DPT provider. Elevation or GIS data will be provided via client for cross sections and 3D modeling service (if applicable). If requested, Eagle Synergistic has the ability to collect gps location and elevation data with the Emlid Reach RS+ or Trimble Geo7x. Additional time will be added to the scope for gps collection. Client is responsible for mapping of HRSC points; locations provided by Eagle Synergistic are field estimates, unless stated otherwise. Normal daily footage will be decreased with Low-Level MIP operations. Normal daily footage may be decreased with dissipation tests. • • • Multiple dissipation tests will reduce footage per day. • Eagle Synergistic field personnel are equipped to work in most weather conditions, to include rain and snow. If a project is delayed or called off by our client due to weather or issues outside of Eagle Synergistic’s control, a standby time fee may apply. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 922 of 36 P a g e | 21 All Eagle Synergistics reports, and the information contained therein, consist solely of qualitative information provided to CR Solutions (the “Client”) for its own independent use. Eagle Synergistics will not provide to the Client or owner(s) of the subject property any recommendations related to its reports or any information contained therein, and Eagle Synergistics hereby disclaims all responsibility related to the same. To such an end, Client hereby releases, remises, forever discharges, and indemnifies Eagle Synergistics, its managers, principals, officers, directors, contractors and employees (the “Releasees”) from and against, and agrees not to bring, pursue, maintain or participate voluntarily in any lawsuit, action or other recourse of whatever kind or nature against the Releasees or any of them for or in connection with, any and all actions, claims, demands, liabilities, losses, damages, expenses (including but not limited to attorneys’ fees), and other harm, of whatever kind or nature, whether at law or in equity or otherwise, whether based on contract or tort or otherwise, whether or not now or hereafter known, suspected or claimed, and whether or not ascertainable or discoverable at the time of execution of this Agreement, which Client, ever had, now has or in the future may have or allege against the Releasees, or any of them, arising out of or relating in any manner to the project contemplated herein. Insurance Eagle Synergistic standardly carries General liability, Contractors Pollution Liability and Professional Liability coverage with a $2,000,000 limit. Additional limits are also available, project specific. Health & Safety Audit and Risk Management Programs O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 923 of 36 P a g e | 22 CLIENT DELIVERABLES AND EXAMPLES An MIHPT log includes (from left to right) an EC, MIP-PID, FID, and XSD detector graphs, HPT injection pressure (top axis) with HPT flow rate (bottom axis), and Absolute Piezometric Pressure (top axis) with estimated hydraulic conductivity (K) (bottom axis) with a line showing where a dissipation test was taken (red triangle), and where DI Viewer calculated the groundwater depth based on the dissipation test (red circle). EC (Grain Size Indicator) Contaminant Detectors HPT Pressure Abs. Piez. Pressure PID FID XSD Tight clay interval Silty sand s Sandy interval Detector responses, indicating a hydrocarbon release Groundwater table Dissipation test High transmissivity zones HPT Flow Est. K (Above) Is an example of a MIHPT Log from a hydrocarbon release indicated by the PID and FID mimicking each other. The HRSC signatures are indicators for contaminants, lithological, and hydrogeological properties. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 924 of 36 P a g e | 23 EC (Grain Size Indicator) Contaminant Detectors HPT Pressure PID XSD FID Sandy interval Tight clay interval Detector responses, indicating a chlorinated ethene Low permeability High permeability Low permeability (Above) Is an example of a MIHPT Log from a chlorinated release. HPT Flow Along with the above boring logs which are sent during the day throughout the course of the project, Eagle Synergistic will also provide cross-sectional views with different overlays. Cross-sectional views help compare each boring log’s parameters on a larger scale. Our virtual project managers will email cross-sections and overlays throughout the project to assist in making real time decisions. MIP-01 MIP-02 MIP-03 MIP-04 MIP-05 MIP-06 Source area detected - shallow release Stepping out from the source area Full delineation - due to detecting the edge of the plume (Above) A series of MIHPT logs from a site contaminated with fuel hydrocarbons displays the PID (green (Above) A series of MIHPT logs from a site contaminated with fuel hydrocarbons displays the PID line, green shading) detector response overlaid on the EC (black line, black shading). Visualizing the detector response overlaid on the EC. Visualizing the lithology and contaminated zone together helps lithology and contaminated zone together helps make more accurate remediation decisions and designs. make more accurate remediation decisions and designs. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 925 of 36 P a g e | 24 MIP-01 MIP-02 MIP-03 MIP-04 MIP-05 MIP-06 Tight clay interval with low permeability Sandy interval with high permeability Silty sand Clay seam (Above) A series of MIHPT logs that display the EC (black line, grey shading) overlaid on the HPT Pressure Max (blue line, blue shading). Cross sectional views enhance understanding of lithological and hydrogeological properties. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 926 of 36 P a g e | 25 3D Modeling and Visualizations Eagle Synergistic offers an optional 3D visualization service utilizing mapping, viewing, and modeling software. This interactive simulation can allow the client to simultaneously visualize the contamination plume(s), source(s), lithology intervals, high transmissivity zones, aquitards, topography, water tables, and migration pathways. Previously obtained groundwater and soil data can also be integrated into our models. Clients will receive a comprehensive 3D report which includes multiple views and descriptions of each 3D visualization. Eagle Synergistic will provide education on how to use the 3D viewer which allows the client to zoom, rotate, and change the isolevels, indicating different sensitivities of the contaminant plume and other properties. To assist the client in designing the remediation phase, Eagle Synergistic will also supply multiple videos and a condensed report specifically for remediation vendors to better understand the HRSC data. (Above) Models a large, chlorinated release (XSD and PID) migrating through high transmissivity zones (HPT/Est. K) and restricted by confining layers (EC). O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 927 of 36 P a g e | 26 Store (Above) Shows a 3D model of the subsurface with HPT Pressure and EC along with a hydrocarbon plume from a UST release. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 928 of 36 Numerous models and views will be supplied as part of the 3D package P a g e | 27 O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 929 of 36 P a g e | 28 OTHER HRSC SERVICES OIHPT (Optical Image Profiler & Hydraulic Profiling Tool) – Optical Image Profiler (OIP) System: A system developed by Geoprobe Systems® for the detection of non-aqueous phase liquid (NAPL) hydrocarbon fuels, oils, and tars in the subsurface. The OIP system uses an UV or green light source to induce fluorescence of the polyaromatic hydrocarbons (PAHs) of the fuels, oils, and tars present in the soil. A down hole camera captures an image of the induced fluorescence. The captured image is then analyzed to determine the area of fluorescence. The NAPL hydrocarbon fuel, oil, or tar is measured as the percent area within the image that contains fluorescence. An OIHPT log includes (from left to right) an EC, fluorescence graph, along with actual fluorescence and visual images, HPT injection pressure (top axis) with HPT flow rate (bottom axis) and Estimated Hydraulic Conductivity (K) (top axis) with Absolute Piezometric Pressure (bottom axis) with a line showing where a dissipation test was taken (red triangle), and where DI Viewer calculated the groundwater depth based on the dissipation test (red circle). . EC (Grain Size Indicator) Fluorescence % Captured Images HPT Pressure Est. K Tight clay interval LNAPL detection Silty sands Low permeability Groundwater table Dissipation test High transmissivity zones High permeability HPT Flow Abs. Piez. Pressure O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 930 of 36 P a g e | 29 LL-MIP (Low Level Membrane Interface Probe) — The LL-MIP operates in a similar manner to our normal MIP tool; however, the LL-MIP enhances detector sensitivity by a factor of approximately 10. LL-MIP operation should be utilized with sites needing PPB level detections. EC (Grain Size Indicator) Contaminant Detectors HPT Pressure Abs. Piez. Pressure PID FID XSD Groundwater table Low Level responses, indicating a comingled hydrocarbon and chlorinated plume. High transmissivity zone Dissipation test Tight clay interval Silty sand interval Sequence of silty sand and clay intervals Tight clay interval (Above) A log completed with the Low-Level MIP configuration identifying PPB level contamination. HPT Flow Est. K OIP-G (Optical Image Profiler-Green) — The OIP-G operates in a similar manner to the OIHPT-UV tools. A green light is used to fluoresce common organic contaminants that yield inconsistent results with standard UV light, such as heavier PAHs (coal tars, creosote, bunker fuels). O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 931 of 36 P a g e | 30 CPT (Cone Penetration Testing) CPT primary measurements include tip resistance(qc), sleeve friction(fs), and pore pressure(u). Tip resistance is a measurement of soil hardness, sleeve friction is an indication of the soil cohesive strength commonly seen with clays, and pore pressure is related to the pressure generated as the cone is advanced as well as an indication to the amount of clay in the formation. HPT-GWS — The HPT-GWS has the capabilities to obtain numerous discrete groundwater samples, while collecting EC and HPT pressure data for lithological and hydrogeological properties. DI water is used to purge the sampling line in between every sample which allows multiple samples to be taken every borehole. With a downhole transducer, we are able to detect zones of high yield. This is an excellent insitu profiling tool to target discrete groundwater samples on PFAS sites. O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 932 of 36 PRICING P a g e | 31 O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 Quotation ForDate:2/12/2023Quotation valid until:8/12/2023Caroline ReynoldsQuotation #: 23.109Prepared by:BCCR Solutionscrsolns@icloud.com512-454-8880Project Manager/RepJob NameEst. Start DateBCJack Brown Cleaners2023QtyUnit PriceLine Total3 $ 2,117.50 $ 6,352.50 3 $ 120.00 $ 360.00 1,800.00$ 3380.00$ 360.00$ Mobilization (roundtrip)11,500.00$ 360.00$ $ 7,432.50 3 $ 3,395.00 $ 10,185.00 $ 420.00 $ - Standby Time (per day) $ 1,850.00 $ - $ - $ - $ - $ 10,185.00 1 $ 1,250.00 $ 1,250.00 $ 4,895.00 $ - $ 825.00 $ - $ 1,250.00 SubtotalDescriptionAddress615 W. MLK, Jr. Blvd, Austin, TXHRSC Command Center vehicle/mobile office and HRSC specialistOvertime charge/hour (applies after 10 hour day per client request)HRSC Subsurface Imaging Field ServicesDrumsPer DiemsDPT daily rig and operator rate Consumables- soil core sample, liners, bentonite, etc. (per day)PotholingPotholing Mobilization (round trip)Training DayDIRECT PUSH DRILLING SERVICES- DPT provider is to be subcontracted by Eagle Synergistic specifically for HRSC advancement. Eagle Synergistic requires a Geoprobe 6600 series or above to advance HRSC tooling. Equivalent AMS PowerProbes can also be approved. Locates, utilities and concerns are responsibility of drilling company and/or client. Eagle Synergstic claims no responsibility regarding issues that arise from utility/locate concerns.(cid:9)HRSC QC setup and training with DPT operators 3-D modeling and visualization- Standard (optional)DPT ProviderIDW DisposalSubtotalConcrete CoringSubtotalReporting and Project ManagementStandby Time (per day)GPS coordinate collection for 3-D modeling per dayHRSC Subsurface Imaging Technical Support ServicesEagle SynergisticOptimizing Technologies, LLC751 Pine Ridge RoadUnit 100Golden, CO 8040313 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 933 of 36 P a g e | 32 O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 378.00$ 234.00$ 175.00$ -$ 3165.00$ 495.00$ PFAS approved HDPE tubing-$ -$ DI water-$ -$ 729.00$ Mobilization and Demobilization from Austin location (daily)345.00$ 135.00$ Per Diems5215.00$ 1,075.00$ 11,100.00$ 1,100.00$ 2,310.00$ 21,906.50$ 21,906.50$ TOTALSales tax- if applicableSUBTOTALSubtotalOIP sapphire windowsMIP membranes*Private Locator is required at client expense/responsibility prior to deploying our HRSC technologies. Eagle Synergistic is not responsible for damages or injuries related to underground utilities.SubtotalProject and equipment setupMobilization and SetupHPT screensHRSC Expendable ItemsThis is a quotation on the services named, with further conditions pertaining to these prices stated in thepdf. Eagle Synergistic carries $5,000,000 in liability insurance, which includes general, pollution, and professional liability. Eagle Synergistic will not commence work without a completed utility locate.Eagle Synergistic’s field specialists and technicians have current OSHA certifications.Net 30 days.To accept this quotation,please sign below and return.13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 934 of 36 P a g e | 33 SIGNATURE PAGE Signature required for the initiation of the project. Client Signature: __________________________ Date: ___/___/______ O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 935 of 36 P a g e | 34 THANK YOU We at Eagle Synergistic look forward to working with CR Solutions and supporting your goals in implementing cutting edge HRSC technology to investigate your contaminated site. We are confident that we can meet or exceed your goals. If you have questions on this proposal, feel free to contact Janet Castle or one of our HRSC specialists at your convenience by email at jcastle@eaglesynergistic.com or by phone at 720-475-0022. We will be in touch with you within a few days to arrange a follow-up conversation on the proposal. Thank you for your consideration, Janet L Castle, PG, President jcastle@EagleSynergistic.com Eagle Synergistic 751 Pine Ridge Rd #100 Golden, CO 80403 Direct: 720-475-0022 Office: 303-305-7783 www.EagleSynergistic.com Locations Nationwide: CO, TX, CA, GA, PA, IL WOSB O: 303-305-7783 | www.EagleSynergistic.com | D: 720-475-0022 13 C14-2025-0090 - West Martin Luther King Jr Blvd and Nueces Street; District 936 of 36