Item 07 - AFD8EMS7&EMS5__Final Design__Angulo_Backup.pdf — original pdf

Backup

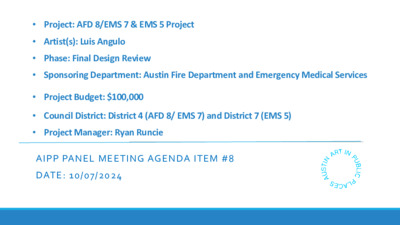

• Project: AFD 8/EMS 7 & EMS 5 Project • Artist(s): Luis Angulo • Phase: Final Design Review • Sponsoring Department: Austin Fire Department and Emergency Medical Services • Project Budget: $100,000 • Council District: District 4 (AFD 8/ EMS 7) and District 7 (EMS 5) • Project Manager: Ryan Runcie AIPP PANEL MEETING AGENDA ITEM #8 DATE: 10/07/2024 AFD 8/EMS 7 EMS 5 AFD 8 / EMS 7 Mural Contract Deliverables COMMUNITY ENGAGEMENT AFD 8, EMS 7, EMS 5 (1) A description of the results of the Community Engagement Plan, and how they are incorporated into the Final Design. During the Summer of 2021 I was fortunate enough to have the opportunity to participate in ride alongside with AFD 8 and EMS 7. During these 8-12 hour shifts of which there were 4 of them, I got to closely observe what a shift as a first responder looks like. All of the personal were very welcoming and I was able to ask as many questions as I wanted. When I went in to this expertience I had very little understanding of the culture and day to day life of first responders when they are on a shift. Not only did I have the opportunity to be at the stations, but I also went on many calls with both fire and EMS. The designs I am submitting are based on the many hours of ride alongside I go to partake in which total over 72 hours. My community engagement consisted in sharing this time with EMS and AFD, and discussing around the dinner table at times, what type of art or imagery would be inspiring for them to see. Some of the feedback I got included: No images alluding to being heroes, no stressful images of first responders on a call, no direct reference to current staff members, a show of the diversity found in the departments, uplifting imagery, inspiring imagery, a reflection of the bond and comrederie and nothing abstract. After several rounds of submitting designs and as result of feedback and the information above the final design I am submitting I feel very strongly reflects the wishes of the community of AFD and EMS. AFD8 / EMS7 Final Design EMS 5 Final Design IW SERIES WALL SYSTEM Concealed Fastener Panel IW-10A, IW-11A, IW-12A, IW-13A, IW-14A, IW-15A TECHNICAL DATA SHEET IW-10A IW-11A IW-12A DESCRIPTION IW-10A Series offers six interesting configurations: IW-10A, IW-11A, IW-12A, IW-13A, IW-14A and IW- 15A. All IW panels share a common lock-joint design which makes them interchangeable on a project. The lock also permits the placement of concealed fasteners, and minimizes moisture intrusion. All IW Series wall panels can be installed in a variety of rainscreen applications to form a complete wall system. Systems may vary from an uninsulated screen wall to MetalWrapTM Series, an insulated composite backup panel system with Advanced Thermal and Moisture Protection (ATMP®). IW-13A IW-14A IW-15A IW-10A SERIES GENERAL DESIGN OPTIONS PANEL THICKNESS 11/2” [38mm] PANEL COVERAGE 12” [305mm] SIDE LAP END LAPS Interlocking Galvanized1 (G90) Aluminum1 (3003-H14) (see standard detail) Shop notched and swaged for vertical applications only 2” [51mm] for 22 [0.76mm] and 20 [0.91mm] gages only4,5,6,8 Rivets may be required for proper alignment. Flash or extrusion for all gages6 (see standard detail) Shop notched and swaged for vertical applications only 2” [51mm] for 0.040” [1.02mm] only4,5,6,8 Flash or extrusion for all other thicknesses6 GAGES (STANDARD) 20 [0.91mm], 22 [0.76mm] 0.040” [1.02mm] GAGES (OPTIONAL) 18 [1.19mm]3,5,7 0.050” [1.27mm]5 STANDARD LENGTH 5 [1.524m] - 25 ft. [7.62m] 5 [1.524m] - 20 ft. [6.096m] STANDARD TEXTURE Embossed2,10 (20 [0.91mm] - 22 [0.76mm] gage only) Embossed2,9 OPTIONAL TEXTURE Smooth Smooth FINISHES See CENTRIA Color Chart See CENTRIA Color Chart 1. Alternate base material, panel lengths and gages may also be available. Contact CENTRIA. 2. Embossing is non-directional. 3. IW-12A and IW-13A are not available in 18 gage. 4. Shop swaged ends are not available for IW-12A, IW-14A, IW-15A. 5. Shop swaged ends are not available for 18 gage steel, 0.050” aluminum. 6. MicroLine Extrusions can be used with horizontally installed panels only. 7. 18 gage cannot be embossed. 8. Swaged for vertical application only 9. 0.050” Embossed (optional gauge) is best effort ONLY 10. Not available in 18 ga. 11. All IW panels are erected from top to bottom when erected in a horizontal application CENTRIA.COM Copyright © 2022 CENTRIA, a NUCOR® company. CENTRIA-TDS-IW10-15-NJ 10/2022 NOTES: 1) at EMS 5, panel seams will run horizontally 2) at EMS7/FS8, panel seams will run verticallyAIPP-USE METAL PANELING FOR EMS 5 and EMS7/FS8 9/19/23 • • • • • IW-10A-15A DESIGN FEATURES & BENEFITS Concealed fastener design minimizes exposed fasteners Common lock-joint design makes all IW series panels interchangeable on a project & minimizes moisture intrusion Can be installed vertically or horizontally Excellent for new construction and retrofit projects Cost-effective, all-weather installation capability shortens installation time; permits fast-track scheduling • Panels are available with embossed or smooth finishes IW-10A-15A TESTING TEST CHARACTERISTIC TEST METHOD TEST TITLE RESULTS ENVIRONMENTAL IW products are intended to be used only as rainscreens; an appropriate air & moisture barrier must be installed behind the product to comply with code requirements. STRUCTURAL Approved for non-HVHZ only; see FL3174. WIND LOADS ASTM E72 Determines structural performance under uniform static air pressure difference See load-span tables for allowable spans/loads under positive or negative loading. AIR LEAKAGE WATER PENETRATION IMPACT RESISTANCE NOTES A. For information on special applications, contact your local CENTRIA Sales Representative. B. All IW panels may be used on walls & soffits but not on roofs. C. Panel length tolerance is ± 1/4” [6mm]. D. For protective coatings - see CENTRIA color chart. E. Oil canning within mill tolerances will not be cause for rejection. F. G. Horizontal Panels must be erected from top to bottom. Panels must be ordered as “horizontal” when used in a horizontal application. PRISMATIC™ SOLID COLOR SERIES SUNDANCE™ MICA AND METALLIC SERIES CUSTOM COLOR ALLURA™ EARTH TONE SERIES COATING SYSTEMS PRISMATIC SERIES COLORS COATING SYSTEMS SUNDANCE SERIES COLORS COATING SYSTEM COATING SYSTEM Fluorofinish® Coating System is a durable, solid-color finish for architectural applications. The graffiti-resistant, PVDF coating contains 70% Kynar 500®/Hylar® 5000 resins. 3 2 1 1. 0.8 mil [20 micron] nominal PVDF Color Coat* 2. 0.2 mil [5.1 micron] nominal Primer 3. Metal Substrate Duragard® Coating Systems offer a high- build architectural finish that provides reliable performance in color retention and fade resistance. Added protection is obtained with our Duragard® Plus coating that includes an additional 0.8 mil PVDF clear top coat. 3 2 4 1 Duragard Plus 1. 0.8 mil [20 micron] nominal PVDF Clear Coat* 2. 0.8 mil [20 micron] nominal PVDF Color Coat* 3. 0.8 mil [20 micron] nominal Primer 4. Metal Substrate Duragard 0.8 mil [20 micron] nominal PVDF Color Coat* 0.8 mil [20 micron] nominal Primer Versacor® ELITE Coating Systems are premium, high-build, multi-layer metal coating systems that provide the highest levels of protection in the harshest climatic or environmental conditions. Versacor® ELITE PF features a solid color PVDF top coat. Versacor® ELITE MX has a PVDF pearlescent effect top coat. Both coatings are excellent for corrosive architectural applications and abrasion resistance. 3 2 1 1. 0.8 mil [20 micron] nominal PVDF Top Coat 2. 2.0 mil [50.8 micron] nominal Versacor Elite Barrier Coat Primer 3. Metal Substrate — G-90 galvanized steel, aluminum Versacor® ELITE AM combines the superior corrosion resistance of the Versacor Elite barrier coat with a PVDF metallic color coat and the extra protection of another clear coat. 3 2 4 1 1. 0.5 mil [12.7 micron] nominal Clear Coat 2. 0.8 mil [20 micron] nominal PVDF Metallic 3. 2.0 mil [50.8micron] nominal Versacor Effect Color Coat Elite Barrier Coat 4. Metal Substrate — G-90 galvanized steel, aluminum Available in a wide range of colors and Fluorofinish, Allura, Duragard and Versacor Elite Coating Systems. 179 Regal White 996 Crushed Ice 993 Off-White 995 Cambridge White 310 Bone White 994 Colonial White 5012 Marble 992 Lee Ivory 133 Sandstone 1760 Limestone 142 Surrey Beige 9910 Light Seawolf 9911 Pebble 997 Prism Yellow 5444 Aged Copper 977 Moss 9933 Cypress Olive 978 Hunter Green 183 Evergreen 9932 Hartford Green 177 Slate Blue 9926 Arabian Blue 974 Teal Blue 9928 Cherokee Blue 200 Deep Blue Sea 9930 Night Horizon 9923 Granite 971 Chromium Gray 9917 Light Gray 9918 Dove Gray 9919 Fashion Gray 181 Slate Gray 9922 Steel Gray 9921 Charcoal Gray 9914 Midnight Bronze 154 Dark Bronze 9916 Rich Black 9912 Sage Brown 1243 Mocha 9937 Mauve Please note all finish thicknesses shown are nominal. *Polyvinylidene Fluoride (PVDF) coat contains 70% Kynar 500 or Hylar 5000 resin Kynar 500 is a registered trademark of Arkema Inc. Hylar 5000 is a registered trademark of Solvay Solvents, Inc. What is Reverse Side Coating Protection? As an added layer of protection for exterior walls, 2-mil-thick [50.8 micron] Versacor barrier coat with a 0.5 mil [12.7 micron] polyester topcoat is applied to the interior liner of the metal substrate to protect against corrosion. 156 Colonial Red 999 Aspen Gold 3 4 2 1 1 1. 0.8 mil [20 micron] nominal PVDF Color Coat* 2. 0.2 mil [5.1 micron] nominal Primer 3. Metal Substrate Sundance AM is a Polyvinylidene fluoride (PVDF) 3-coat system that incorporates metal flakes in the color coat. A clear top coat protects the metal flakes and results in an outstanding metallic effect. Sundance Mica is a 2-coat system that provides a pearlescent appearance. Sundance Mica is a high performance PVDF finish that is an excellent, cost effective alternative to metallic finish systems requiring clear coats. Sundance Series Colors are scintillating micas and bright metallics that create truly dynamic aesthetics for your building. The appearance of Sundance Series colors can change as the sun moves across the sky, making color an active facet of your design. SUNDANCE MICA 2-COAT 9946 Silversmith 9947 Gray Velvet 9949 Copper 9987 Bronze II 9948 Champagne Bronze 9951 Champagne Pearl 9989 Platinum 9988 Brick II 9954 Jade 9955 Blue SUNDANCE AM ALUMINUM METALLIC 3-COAT Custom Color coatings are durable PVDF based finishes available in 2-coat and 3-coat systems. These color coatings offer a bright, vibrant color to any architectural application. If your color choice is not found among our standard colors, contact CENTRIA for a custom color match. 3 2 4 1 Allura is a premium PVDF coating that provides a matte, low-gloss finish, combined with a subtle aggregate texture. 3 2 1 1. 0.8 mil [20 micron] Color Coat 2. 0.2 mil [5.1 micron] nominal PVDF Primer 3. Metal Substrate ALLURA TERRA COTTA SERIES COLORS 9956 XL Rosalind Rose 9957 XL Silver 9958 XL Champagne Gold 9959 XL Light Bronze 9960 XL Medium Gray ALLURA NATURAL STONE SERIES COLORS 781 Adobe 782 Lava Rock 783 Sienna 784 Clay 785 Sedona 3 2 9962 XL Silver Gray 9963 XL Copper Metallic 9964 XL Medium Bronze 9965 XL Dark Bronze 9967 XL Pewter 786 Beach 787 Grain 788 Shale 789 Bedrock 790 Quarry CELESTIAL™ EFFECTS LUMINOUS SERIES CELESTIAL EFFECTS SERIES COLORS KOLORSHIFT™ IRIDESCENT SERIES KOLORSHIFT SERIES COLORS 1. 0.5 mil [12.7 micron] nominal PVDF Clear Coat* 2. 0.8 mil [20 micron] nominal PVDF Color Coat* 3. 0.2 mil [5.1 micron] nominal Primer 4. Metal Substrate Kolorshift Series is an iridescent Polyvinylidene fluoride (PVDF) architectural coating that offers a whole new world of design possibilities. The color of the metal surface will change depending on the viewing angle or direction of sunlight. The result is a continuous iridescent color gradient. Custom colors are available with Kolorshift. 731 Hemlock 732 Dusty Rose 733 Green Shimmer 734 Purple Rain 735 Lightning Storm 806 Bronze Gold 807 Black Silver 808 Blue Silver 1. 0.5 mil [12.7 micron] nominal PVDF Clear Coat* (where required) 2. 0.8 mil [20 micron] nominal PVDF Color Coat* 3. 0.2 mil [5.1 micron] nominal Primer 4. Metal Substrate COATING SYSTEM Celestial is a pre-finished coating that offers deep, brilliant colors that shimmer in the light. 3 4 2 1 1. 0.8 mil [20.3 micron] nominal 2. 0.8 mil [5.1 micron] nominal Top Coat Color Coat 3. 0.2 mil [10.2 micron] nominal Primer 4. Metal Substrate (thickness may vary) Cost of CENTRIA coatings may vary depending on specific color and finish selection. Colors shown are for preliminary selection only. Printed colors can vary from actual painted material. CENTRIA panel finishes are applied using the coil coating process. Metallic and mica finishes may exhibit some directionality in the coating color. When specifying micas and metallic colors, directionality of the coating must be considered during estimating, fabricating, and installation. COATING SYSTEM 3 2 4 1 1. 0.8 mil [20 micron] nominal PVDF Top Coat* 2. 0.5 mil [12.7 micron] nominal Base Coat 3. 0.2 mil [5.1 micron] nominal Primer 4. Metal Substrate 801 White Gold 802 White Silver 803 Slate Silver 804 Platinum Silver 805 Charcoal Silver NOTE: Galvalume®, stainless and aluminum may not be available for all product profiles or coating systems. Galvalume® offers improved heat resistance only when used unpainted. NOTE: Non-stock colors may be subject to a minimum quantity requirement or small order charges. Please consult CENTRIA. INTERIOR COLOR Unless specified otherwise, CENTRIA will provide a standard backer coat on the reverse side of single skin panels. Color may vary. CENTRIA will provide a standard finish offering for the interior surfaces of foam panels. Other finishes available upon request. A/E Confirm 9921 CharcoalGray @ Station 7.COLOR FOR EMS7/FS8COLOR FOR EMS 5 SUBMITTALS RELEASE BY DATE 2 INSTALLATION OF JA VERTICAL CONCEPT SERIES PANELS RETAINER EXTRUSIONS WITH MB & HEAD FIELD FABRICATION OF FRONT ADAPTER EXTRUSION SP4142 REFERENCE DETAILS FOR APPLICATION 2 INSTALLATION OF JA HORIZONTAL CONCEPT SERIES PANELS RETAINER EXTRUSIONS WITH MB & HEAD JAMB COVER EXTRUSION SP4143 HEAD COVER EXTRUSION SP4143 AND IN PLACE 2F 1 VERTICAL or HORIZONTAL CONCEPT SERIES PANELS INSTALLATION OF JA RETAINER EXTRUSIONS WITH MB & HEAD FIELD NOTCH HEAD RETAINER EXTRUSION SP4141 1A JAMB RETAINER EXTRUSION SP4141 ATTACHMENT OF HEAD RETAINER EXTRUSION SP4141 TO 1C FIELD NOTCHED JAMB RETAINER EXTRUSION SP4141 1B FIELD INSTALL CLOSURE FLASH TO JAMB COVER EXTRUSION SP4143 2C JAMB COVER EXTRUSION SP4143 FIELD INSTALL HEAD COVER EXTRUSION SP4143 AND THEN INSTALL 2E FIELD NOTCH JAMB COVER EXTRUSION SP4143 INTERIOR SIDE SHOWN 2A FIELD NOTCHED JAMB COVER EXTRUSION SP4143 2B 2D HEAD EXTRUSION SP4143 - TOP VIEW FABRICATION REQUIRED BEFORE INSTALLATION PROJECT NUMBER: DATE: APPROVED APPROVED AS NOTED REVISERESUBMIT DRAWN BY: SCALE: (cid:57)(cid:67)(cid:70)(cid:71) (cid:35)(cid:84)(cid:69)(cid:74)(cid:75)(cid:86)(cid:71)(cid:69)(cid:86)(cid:87)(cid:84)(cid:67)(cid:78) (cid:53)(cid:91)(cid:85)(cid:86)(cid:71)(cid:79)(cid:85) ARCHITECT ATTENTION INSTALLER IN THE EVENT THAT A DISCREPANCY OR ERROR ARISES WITH MATERIALS SHIPPED FOR THIS PROJECT OR THESE CONSTRUCTION DRAWINGS THE INSTALLER MUST NOTIFY WADE PRIOR TO CORRECTING. IF WADE IS NOT NOTIFIED, WADE WILL NOT HONOR BACKCHARGES BY ANY PARTY INVOLOVED. PROJECT NAME: ALTHOUGH CONCEPT SERIES PANELS ARE DETAILED, OTHER HORIZONTAL PROFILES ARE SIMILAR. REFERENCE THE PROFILE SPECIFIC MicroLine DETAILS FOR ADDITIONAL INFORMATION. NOTE: THE FINAL SELECTION AND DESIGN OF THE WEATHER-RESISTIVE BARRIER & AIR BARRIER SYSTEM IS THE RESPONSIBILITY OF THE PROJECT ARCHITECT ANDOR DESIGN ENGINEER. (cid:57)(cid:67)(cid:70)(cid:71) (cid:35)(cid:84)(cid:69)(cid:74)(cid:75)(cid:86)(cid:71)(cid:69)(cid:86)(cid:87)(cid:84)(cid:67)(cid:78) (cid:53)(cid:91)(cid:85)(cid:86)(cid:71)(cid:79)(cid:85) THIS STAMP MUST BE SIGNED BY AN AUTHORIZED REPRESENTATIVE OR BUYER BEFORE RETURNING TO WADE. THESE DRAWINGS ARE SUBMITTED FOR AND REQUIRE BUYER’S APPROVAL. CHANGES OR VERIFICATIONS MUST BE NOTED AND RETURNED TO WADE BY AN OFFICER OR AUTHORIZED REPRESENTATIVE OF BUYER’S COMPANY BEFORE FABRICATION CAN PROCEED. DRAWINGS MAY VERY FROM PROJECT DRAWINGS, SPECIFICATIONS OR DOCUMENTS PROVIDED BY BUYER AND SUCH DIFFERENCEDVARIANCES ARE MADE IN ORDER TO CONFORM TO WADE’S OR INDUSTRY STANDARDS. IT IS THE BUYERS SOLE RESPONSIBILITY TO VERIFY ALL DIMENSIONS, QUANTITIES, LENGTHS, FINISHES AND MATERIALS. BUYER’S SIGNATURE BELOW CERTIFIES THAT ALL DIMENSIONS, QUANTITIES, LENGTHS, FINISHES AND MATERIALS HAVE BEEN VERIFIED, ARE CORRECT AND ARE APPROVED OR APPROVED AS NOTED. THESE DRAWINGS DO NOT RELIEVE BUYER OF ITS OBLIGATIONS IN CONNECTION WITH THE CONTRACT DOCUMENTS AND ARE SOLELY OUT INTERPRETATION OF THE PROJECT DRAWINGS, SPECIFICATIONS, OR DOCUMENTS PROVIDED BY BUYER. BY: DATE: NOT FOR CONSTRUCTION FOR APPROVAL ONLY SHEET NUMBER: SUBMITTALS RELEASE BY DATE (cid:57)(cid:67)(cid:70)(cid:71) (cid:35)(cid:84)(cid:69)(cid:74)(cid:75)(cid:86)(cid:71)(cid:69)(cid:86)(cid:87)(cid:84)(cid:67)(cid:78) (cid:53)(cid:91)(cid:85)(cid:86)(cid:71)(cid:79)(cid:85) ARCHITECT 1 VERTICAL or HORIZONTAL CONCEPT SERIES PANELS INSTALLATION OF JA RETAINER EXTRUSIONS WITH MB & SILL FIELD NOTCHED JAMB RETAINER EXTRUSION SP4141 1A 2 INSTALLATION OF JA WITH VERTICAL CONCEPT SERIES PANELS MB & SILL RETAINER EXTRUSIONS 1B FIELD NOTCH SILL RETAINER EXTRUSION SP4141 JAMB RETAINER EXTRUSION SP4141 ATTACHMENT OF SILL RETAINER EXTRUSION SP4141 TO 1C FIELD NOTCHED JAMB COVER EXTRUSION SP4143 INTERIOR SIDE SHOWN 2A FIELD NOTCHED JAMB COVER EXTRUSION SP4143 EXTERIOR SIDE SHOWN 2B 2D SILL EXTRUSION SP4145 - PLAN VIEW INTERIOR FABRICATION REQUIRED BEFORE INSTALLATION 2 INSTALLATION OF JA EXTRUSIONS WITH HORIZONTAL CONCEPT SERIES PANELS MB & SILL RETAINER JAMB COVER EXTRUSION SP4143 HEAD COVER EXTRUSION SP4143 AND IN PLACE 2F FIELD INSTALL CLOSURE FLASH TO JAMB COVER EXTRUSION SP4143 2C JAMB COVER EXTRUSION SP4143 FIELD INSTALL SILL COVER EXTRUSION SP4145 AND THEN INSTALL 2E ALTHOUGH CONCEPT SERIES PANELS ARE DETAILED, OTHER HORIZONTAL PROFILES ARE SIMILAR. REFERENCE THE PROFILE SPECIFIC MicroLine DETAILS FOR ADDITIONAL INFORMATION. NOTE: THE FINAL SELECTION AND DESIGN OF THE WEATHER-RESISTIVE BARRIER & AIR BARRIER SYSTEM IS THE RESPONSIBILITY OF THE PROJECT ARCHITECT ANDOR DESIGN ENGINEER. ATTENTION INSTALLER IN THE EVENT THAT A DISCREPANCY OR ERROR ARISES WITH MATERIALS SHIPPED FOR THIS PROJECT OR THESE CONSTRUCTION DRAWINGS THE INSTALLER MUST NOTIFY WADE PRIOR TO CORRECTING. IF WADE IS NOT NOTIFIED, WADE WILL NOT HONOR BACKCHARGES BY ANY PARTY INVOLOVED. PROJECT NAME: (cid:57)(cid:67)(cid:70)(cid:71) (cid:35)(cid:84)(cid:69)(cid:74)(cid:75)(cid:86)(cid:71)(cid:69)(cid:86)(cid:87)(cid:84)(cid:67)(cid:78) (cid:53)(cid:91)(cid:85)(cid:86)(cid:71)(cid:79)(cid:85) THIS STAMP MUST BE SIGNED BY AN AUTHORIZED REPRESENTATIVE OR BUYER BEFORE RETURNING TO WADE. THESE DRAWINGS ARE SUBMITTED FOR AND REQUIRE BUYER’S APPROVAL. CHANGES OR VERIFICATIONS MUST BE NOTED AND RETURNED TO WADE BY AN OFFICER OR AUTHORIZED REPRESENTATIVE OF BUYER’S COMPANY BEFORE FABRICATION CAN PROCEED. DRAWINGS MAY VERY FROM PROJECT DRAWINGS, SPECIFICATIONS OR DOCUMENTS PROVIDED BY BUYER AND SUCH DIFFERENCEDVARIANCES ARE MADE IN ORDER TO CONFORM TO WADE’S OR INDUSTRY STANDARDS. IT IS THE BUYERS SOLE RESPONSIBILITY TO VERIFY ALL DIMENSIONS, QUANTITIES, LENGTHS, FINISHES AND MATERIALS. BUYER’S SIGNATURE BELOW CERTIFIES THAT ALL DIMENSIONS, QUANTITIES, LENGTHS, FINISHES AND MATERIALS HAVE BEEN VERIFIED, ARE CORRECT AND ARE APPROVED OR APPROVED AS NOTED. THESE DRAWINGS DO NOT RELIEVE BUYER OF ITS OBLIGATIONS IN CONNECTION WITH THE CONTRACT DOCUMENTS AND ARE SOLELY OUT INTERPRETATION OF THE PROJECT DRAWINGS, SPECIFICATIONS, OR DOCUMENTS PROVIDED BY BUYER. BY: DATE: APPROVED APPROVED AS NOTED REVISERESUBMIT DRAWN BY: SCALE: PROJECT NUMBER: DATE: NOT FOR CONSTRUCTION FOR APPROVAL ONLY SHEET NUMBER: (4) A comprehensive written narrative describing the Final Design, including information about concept and imagery, types and quantities of all materials to be incorporated into the Artwork, and how the Final Design meets the goals outlined in Exhibit B. The mural for AFD 8/EMS7 depicts the hands of first responders from both departments outstretched and gathered in the middle of the composition as a symbol of the teamwork and cooperation that takes place on a daily basis at emergency calls throughout the city. It also symbolizes the diversity found in these departments of people of all ethnic , genders and sexual orientation. This is symbolized by the variety of skin colors that will be shown in the composition as well as other symbols sprinkled throughout the image. The mural for EMS 5 shows a group of cadets that have recently graduated and are looking towards future as first responders with pride and excitement. The people used for the mural are models, not actual staff members and they show the diversity found in the department. This mural design is a symbol of a career you can found pride in by providing care and service to the community. The two proposed murals will be painted using water based paint. The substrate will be treated with an all surface primer that will be sprayed with an airless sprayer. The mural will then receive a two coat basecoat using high quality exterior latex paint. The mural design will then be projected on to the surface and sketched in. The art will be painted and shaded using a combination of brushwork and airbrushing with the same exterior grade latex paints. Upon completion the mural will receive two coats of a UV resistant sealer. Pre-fabrication Review: AFD 8/EMS 7 and EMS 5, Luis Angulo Report Date: April 24, 2024 Note: These comments are based on proposal documents. Because some materials specifications were not available for this report, these should not be considered final or comprehensive recommendations. Project Overview: Mural artist Luis Angulo proposes two large-scale murals, one each on the exteriors of the AFD8/EMS7 and EMS 5 buildings. The full design proposal and exact panel dimensions were not provided for this review, but the provided renderings show panels depicting AFD and EMS workers that appear to be more than 20 feet wide and 16 – 20 feet high, located near the entrances of each building. The AFD8/EMS 7 mural is to one side of the entrance, with a narrow and shallow overhang on one end only; the EMS 5 mural extends around and above the entryway, and is entirely under a shallow roof overhang. Materials and fabrication: At each mural site, a Centria IW-10A metal panel will be installed by the Public Works Department. The specifications provided imply that it may be either galvanized steel or aluminium, but the type of metal to be used was not confirmed at the time of this review. The artist will create the mural onsite. The artist will first spray-coat the panels with two coats of Kilz 3 Premium Heavy-duty High Hide Sealer and Stain Blocker, a proprietary acrylic primer. The murals will then be brush painted with Benjamin Moore Aura Exterior Paint (exact paint colors not specified for this review). The completed murals will be spray-coated with two topcoats of Modern Masters Masterclear Supreme Clear Coat, a polyurethane formulated with UV stabilizers. Materials and fabrication comments and recommendations: • The artist estimates a lifespan of 25 years. The primer, paint and topcoat system specified is not expected to have a 25-year exterior lifespan without renewal. This is not a materials choice problem: at present no mural paint system is known that will last 25 years in an outdoor exposure without maintenance. • Metal undergoes considerable dimensional changes with thermal fluctuation. The differences between the thermal expansion of any type of metal and of acrylic coating/paint materials may promote accelerated cracking and delamination of all of the applied layers, because the underlying substrate will expand and contract to a greater degree than the acrylic materials can stretch. • Kilz Customer Care Representative Amanda Rodriguez stated that Kilz 3 Premium Heavy-duty High Hide Sealer and Stain Blocker is suitable for use with a prepared aluminium or galvanized steel surface; it is not suitable for use with carbon steel, any other non-galvanized ferrous alloy, copper, or any other metal.1 • Surface preparation is absolutely critical to primer adhesion and mural longevity. Rodriguez declined to provide adhesion test results but confirmed that the primer “has been tested for adhesion.” Once the exact metal alloy to be used is identified, contact 1 Amanda Rodriguez, Kilz Customer Care Representative, personal communication April 23, 2024. Rodriguez recommends considering Kilz Adhesion for other metals. PO Box 6803 Austin, TX 78762 ( +1) 512.843.2123 j.unruh@outlook.com the primer manufacturer for specific recommendations for surface preparation to ensure the best adhesion possible. In general, Rodriguez recommends etching, sandblasting, or sanding surfaces prior to primer application. • Rodriguez declined to provide a lifespan estimate for Kilz 3 Premium Heavy-duty High Hide Sealer and Stain Blocker, noting that lifespan in part depends on paint and topcoat lifespans.2 • Kilz product information states, “only apply if surface, air and product temperatures are between 50°- 90°F” – relevant in Austin’s climate. • Benjamin Moore Aura Exterior Paint is covered by a lifetime warranty against blistering, peeling, and weathering to an exposed surface,3 but it is important to note that the warranty is conditional on application, and it does not cover color shift or degradation of the polymer. • Pigment light stability is a major factor in mural longevity. UV stabilizers are engineered to slow UV degradation of the polymer into which they are introduced; they do not block all UV light to a pigment layer. Even under a UV-stabilized topcoat, pigments can alter. The exact Benjamin Moore Aura Exterior Paint colors to be used were not specified for this review. For one list of light-stable mural pigments manufactured by a different supplier, see https://goldenartistcolors.com/resources/painting-exterior-murals. In some cases, color formulations can be similar between brands of acrylic paints, but it is recommended to confirm light stability with Benjamin Moore once the exact paint colors to be used are selected. • Even under a UV-stabilized topcoat, the acrylic paint binding media can eventually yellow and destabilize. Conservator Leslie Rainer (Getty Conservation Institute Senior Project Manager) has written, “Severe breakdown of the paint binder can be seen on murals after as little as 10 years—especially those works exposed to direct sunlight.”4 • There is debate in conservation about suitable topcoats for exterior murals with differences of opinion and no clear winner across every situation. The budget for both topcoat and for maintenance are considerations; other considerations are: how will graffiti removal be accomplished – with a sacrificial layer, or with a water- or solvent- resistant layer that could be power-washed or treated with chemicals that otherwise would destroy the paint underneath? How will the coating age, and what is the expected lifespan? Should the coating be renewable or should it be considered permanent, and if permanent, how long before the appearance of the aged topcoat will effectively destroy the mural? Within the context of this debate, polyurethane has pros and cons. On the pro side, though Modern Masters’ technical support representative Gina (surname not provided) declined to estimate a lifespan for their product,5 in one study, a different UV- stabilized exterior polyurethane exhibited a lifespan of 10 years6 – relatively good for a topcoat. Polyurethane is durable enough to withstand some removal of graffiti and other surface accumulations. If properly applied, until it develops microcracks, polyurethane can prevent water ingress to the paint layers that could swell and detach the acrylic paint. On the con side, degradation can manifest visually as clouding or yellowing (Modern Masters representative Gina cautioned that Masterclear Supreme Clear Coat 2 Amanda Rodriguez, Kilz Customer Care Representative, personal communication April 23, 2024. 3 https://www.benjaminmoore.com/en-us/aura-ext-lifetime-warranty 4 Rainer, Leslie. 2004. “The Conservation of Outdoor Contemporary Murals.” GCI Newsletter 18 (January): 6. 5 Gina (surname not provided), Modern Masters Product Technical Support, personal communication April 23, 2024. Gina correctly noted that lifespan is conditional on a wide range of factors, and said, “it could be 3 years, it could be 5 years, it could be longer; it just depends on your exact situation.” 6 Nguyen, Thien Vuong, Xuan Hien Le, Phi Hung Dao, Christian Decker, and Phuong Nguyen-Tri. 2018. “Stability of Acrylic Polyurethane Coatings under Accelerated Aging Tests and Natural Outdoor Exposure: The Critical Role of the Used Photo-Stabilizers.” Progress in Organic Coatings 124 (November): 137–46. https://doi.org/10.1016/j.porgcoat.2018.08.013. Prefabrication review: AFD 8/EMS 7 and EMS 5, Luis Angulo April 24, 2024 J. Unruh Page 2 of 4 can be expected to yellow7); and physically as microcracking that allows water ingress to water-susceptible acrylic paint, visible cracking, and detachment. Polyurethane over acrylic paint is unlikely to be removable without damage to the paint layers underneath. New polyurethane coatings can be applied over degraded coatings, but once degradation occurs, visible alteration will be permanently visible. The presence of a non- removable polyurethane coating over the paint will impact how any damage can be repaired. • Neither installation site completely protects the mural from rain exposure. Exposure will hasten deterioration of all media. Rain run-off marks (localized deterioration) may develop over time. • The highly thermal conductive metal substrate may amplify freeze-thaw damage. Installation: Installation will be engineered and completed by the Public Works Department. Installation was not reviewed for this report. Maintenance: The artist recommends, “If dust or dirt collect on the surface of the mural they will need to be rinsed off with water (NOT A PRESSURE WASHER). Other than that they wont need any other type of maintenance.” On the maintenance form, the artist clarifies that “water and soap with a rag or soft cloth” should be used. The artist specifies that if there is paint cracking or loss, the artist should be contacted. Maintenance comments and recommendations: • All outdoor artwork surfaces accumulate bird droppings, grime, car exhaust particulates, chewing gum, and other residues. The lower sections of both murals are additionally susceptible to accidental scratches and abrasion, and may accrue stickers, tagging, scratched graffiti, and other vandalism. Periodic inspection and cleaning should be scheduled and budgeted. • Consult with the artist as to how to proceed should graffiti removal be necessary. • Depending on the type of graffiti, removal may require more invasive cleaning methods than cloth-applied soap and water. Modern Masters representative Gina was of the opinion that the polyurethane topcoat would stand up to pressure washing.8 Testing is advised prior to any pressure washing. In the event of paint cracking or loss, the artist should be contacted. Ideally, that consultation would be in collaboration with a qualified mural conservator. First, conservators are trained to not just disguise problems but to diagnose deterioration and address root causes. Second (and more controversially), artist repairs, and in particular, repainting, can result in alterations to the artwork, both unintentional and intentional.9 Whether an artist relinquishes rights to alteration once an artwork has been purchased is a question that has generated considerable debate: AIPP may want to formulate a stance on that issue. • Note that because the topcoat is unlikely to be removable without damage to underlying paint, repainting is not straightforward. • Once paint colors have shifted, new paint may not exactly match the aged paint color. 7 Gina, Modern Masters Product Technical Support, personal communication April 23, 2024. 8 Gina, Modern Masters Product Technical Support, personal communication April 23, 2024. 9 For an example of how well-meaning repainting has unintentionally altered a mural, compare photos of Daniel Johnston’s “Hi How Are You” mural as painted to its present form. Prefabrication review: AFD 8/EMS 7 and EMS 5, Luis Angulo April 24, 2024 J. Unruh Page 3 of 4 Additional comments: • For a short, non-technical overview of some of the discussion points surrounding long- term preservation of murals, see Rainer, Leslie. 2004. “The Conservation of Outdoor Contemporary Murals.” GCI Newsletter 18 (January): 4–9; available at https://www.researchgate.net/publication/285680405_The_conservation_of_outdoor_co ntemporary_murals#fullTextFileContent General recommendations: • Information that should be retained in the AIPP file includes: • Specifications for all materials used in final design, including panel material, panel fastener specifications, specifications for any other mounting hardware, primer specifications, paint specifications including exact colors used, and topcoat specifications. • Detailed installation diagrams, including all dimensions, panel configuration diagrams, exact placement of mounting hardware, wall construction details including any sub-wall features (studs, wiring or other infrastructure conduits). • Artist's statement re: • intended appearance: the degree of abrasion or scratches, cracking, lifting paint or paint loss, discoloration, or other alterations that would be considered acceptable before the alteration would need to be addressed, or before the mural would need to be de-installed. • Whether or not it would be permissible to re-site the murals in the future, including whether it would be permissible to re-site the murals indoors. Prefabrication review: AFD 8/EMS 7 and EMS 5, Luis Angulo April 24, 2024 J. Unruh Page 4 of 4 (6) Samples of all materials proposed by the Artist to be used in the Artwork. On request by the City, the Artist shall provide the proposed quantities, manufacturer specifications, warranties materials safety data sheets, and other requested information about the proposed materials. SPEC SHEET Primer Base T E C H N I C A L D A T A S H E E T T E C H N I C A L D A T A S H E E T HEAVY-DUTY HIGH HIDE SEALER & STAIN BLOCKER N O. 1 300 PRODUCT SPECIFICATIONS: SURFACE PREPARATION: CLEAN UP: PRODUCT INFORMATION KILZ® PREMIUM primer is a superior quality, fast drying, low odor, very low VOC, water-based primer-sealer-stainblocker. It has excellent adhesion and provides a mildew resistant coating making it ideal for use in moisture-prone areas. KILZ PREMIUM primer blocks most medium to heavy stains caused by water, tannin, ink, pencil, felt marker and grease. Its thicker high hiding formula hides surface imperfections and prepares the surface better for painting. Works with oil and water-based paints. Not recommended for floors. RECOMMENDED USES: Use on properly prepared interior and exterior surfaces, such as: • Concrete • Stucco • Wood • Paneling • Brick • Drywall • Cement Board Siding • Masonry • Plaster • Painted Metal • Properly Prepared Glossy Surfaces Tint Bases/Max Tint Load: No. 1300 128 oz. / 2 oz. Resin Type: Acrylic Polymer Weight per Gallon: 10.9 lbs. % Solids by Volume: 43% % Solids by Weight: 56% VOC: < 5 g/L excluding colorant Flash Point: N/A Viscosity: 95 – 105 KU Recommended Film Thickness: Wet: 5.3 mils / Dry: 2.3 mils @ 300 sq ft/gal Wet: 4.0 mils / Dry: 1.7 mils @ 400 sq ft/gal Coverage: 300 – 400 sq ft/gal depending on the surface texture, porosity and application method. Does not include the loss of material from spraying. APPLICATION: Brush: Nylon/polyester blend Roller: 3/8" – 3/4" nap Tip: .015" – .021" Filter: 60 mesh Airless Spray: Fluid pressure of 1,800 – 3,000 psi The surface must be clean, free of dust, grease, wax, peeling paint, mold, mildew and wallpaper paste. If washing is necessary, use a non-soapy detergent or a TSP substitute. Rinse well and allow to dry. Peeling or Checked Paint: AScrape off loose paint and sand to a smooth surface. Sanding or removal of paint containing lead is hazardous. Unpainted, exterior wood exposed to sun and/or moisture longer than 2 – 4 weeks must be cleaned and sanded before priming.* Glossy Surfaces: For maximum adhesion, scuff sand thesurface thoroughly before priming.* Masonry, Brick, Stucco and Plaster: KILZ PREMIUM Interior/Exterior Water-Based Primer may be used on clean, dry, aged masonry surfaces. New masonry must be allowed to cure (dry) at least 30 days before applying KILZ PREMIUM Interior/Exterior Water-Based Primer. Fire Restoration: It is critical to clean smoke damaged surfaces thoroughly before priming. Primary Recommendation: KILZ RESTORATION™ for water-based primer; KILZ® ORIGINAL and KILZ ORIGINAL INTERIOR/ EXTERIOR for oil-based primer.. *WARNING! If you scrape, sand or remove old paint, you may release lead dust. LEAD IS TOXIC. Contact the National Lead Information Center at 1-800-424-LEAD or visit www.epa.gov/lead. TEST SPECIFICATIONS: Thinning: Not recommended. Product is formulated for use at package consistency only. Dry Time: @ 77°F, 50% RH Longer dry time required in cooler temperatures and in higher humidity. To Touch: 30 minutes To Paint: 1 hour Flexibility ASTM D522 - Pass Biological Growth ASTM D3274 - Pass COMPLIES WITH THE BELOW AS OF 1/1/2019 SCAQMD CARB OTC LADCO AIM YES YES YES YES YES LEED v.3 (2009)† LEED v.4† MPI GREENGUARD† † CHPS YES YES 6, 39 YES YES †Please visit www.usgbc.org/LEED for additional details. Clean all tools and equipment with clean water. For disposal of empty containers and unused product, contact your household refuse collection service. CAUTIONS/LIMITATIONS: • Protect from freezing. • For best results, apply at temperatures between 45°F – 90°F. Temperatures above 90°F may affect the application such as drying too fast. Avoid painting in direct sun. • Shelf life under normal conditions is 2 years unopened. • Not for use on floors. GENERAL INFORMATION: WARNING Cancer and Reproductive Harm– www.P65Warnings.ca.gov CAUTION IRRITANT Avoid contact with eyes. May cause eye, nose and throat irritation. Avoid breathing of dust, vapors or spray mist. Open windows and doors or use other means to ensure fresh air entry during application and drying. If you experience eye watering, headache or dizziness or if air monitoring demonstrates vapor/ mist levels are above applicable limits, wear an appropriate, properly fitted respirator (NIOSH / MSHA TC -23C or equivalent) during and after application. Follow respirator manufacturer’s directions for respirator use. Close container after each use. Wash thoroughly after handling and before smoking or eating. FIRST AID: If swallowed, do not induce vomiting. Get medical attention immediately. If you experience difficulty in breathing, leave the area to obtain fresh air. If continued difficulty is experienced, get medical attention immediately. In case of eye contact, flush eyes immediately with plenty of water for at least 15 minutes and get medical attention. This information is provided “as is” and no representations or warranties, either expressed or implied, of merchantability, fitness for a particular purpose or of any other nature are made with respect to this information or to any product referred to in this information. For SDS or to consult with a technical service representative, call 1-877-KILZ-PRO. ©2019 Masterchem Industries LLC, 3135 Old Hwy M, Imperial, MO 63052-2834. ††GREENGUARD is a registered trademark of UL Company Revised 03/2019 1 of 2 SPEC SHEET: Exterior Latex Paint AURA® WATERBORNE EXTERIOR LOW LUSTRE N634 Primer Systems AURA® Waterborne Exterior is self‐priming on most properly prepared substrates, including wood, fiber cement board, hardboard, nonferrous metals and cured masonry surfaces. On bare substrates two coats are required; previously painted surfaces can be finished with 1 or 2 coats. Special Note: Certain custom colors require a Deep Color Base Primer tinted to a special prescription formula to achieve the desired color. Consult your retailer. Wood, and engineered wood products: Self‐priming Bleeding Woods (Redwood, Cedar, etc.): Fresh Start® Exterior Deck & Siding Primer (094) or Fresh Start® High‐Hiding All Purpose Primer (046) Hardboard Siding, Bare or Factory Primed: Self‐priming Vinyl Siding & Vinyl Composite: In most cases, a primer is not necessary. Only areas of pitted and porous vinyl siding must be primed. In these cases, we recommend Fresh Start® High‐Hiding All Purpose Primer (046) Colors that are safe for use on vinyl siding ‐ Do not paint vinyl with any color darker than the original color or having a Light Reflective Value (LRV) of less than 55 unless it is in the Benjamin Moore approved Colors for Vinyl palette and comports with the specific vinyl manufacturer guidelines when making the color selection and painting. Otherwise, the color will absorb more heat, possibly causing the siding to warp, resulting in additional repairs and expenses. Rough or Pitted Masonry: Ultra Spec® Masonry Interior/Exterior Hi‐Build Block Filler (571) Poured or Pre‐cast Concrete/Fiber Cement Siding: Ultra Spec® Masonry Interior / Exterior 100% Acrylic Masonry Sealer (608) or Masonry High Build Primer (N609) Ferrous Metal (Steel and Iron): Ultra Spec® HP Acrylic Metal Primer (HP04) or Super Spec HP® Alkyd Metal Primer (P06) Non‐Ferrous Metal (Galvanized & Aluminum): All new metal surfaces must be thoroughly cleaned with Corotech® Oil & Grease Emulsifier (V600) to remove contaminants. New shiny non‐ferrous metal surfaces that will be subject to abrasion should be dulled with very fine sandpaper or a synthetic steel wool pad to promote adhesion. Self‐priming once properly prepared. Compliance & Certifications OTC OTC II CARB CARB07 CARB19 UTAH AZMC SCAQMD Pass Pass: (< 0.2) ASTM D6904 Wind Driven Rain 1 coat Masonry Sealer 608 or Masonry Primer N609; 1‐2 coats AURA® N634 ASTM D1308 Alkali Resistance 1 coat Masonry Sealer 608 or Masonry Primer N609; 1‐2 coats AURA® N634 ASTM D1653 Water Vapor Permeance ASTM D3273/D3274 Mildew Resistance Test ASTM D522/522M Flexibility ASTM D2370 Elongation & Tensile Strength MPI 151 % 422 PSI 31 perms Pass: No Growth Pass: No Cracking 315 LIMITED LIFETIME WARRANTY: Benjamin Moore & Co. warrants that this product when used in accordance with the label instructions, will not: 1. blister from properly prepared and primed surfaces, 2. peel from properly prepared and primed surfaces, and 3. wear down or weather to expose the previously painted surface. This warranty shall be effective for so long as you reside in your home and is made to the original residential consumer paint purchaser. This warranty is non‐transferable. If this product fails to perform as explained above when used according to label instructions within the warranty period, Benjamin Moore & Co. will, upon presentation of proof of purchase (original sales receipt), provide an equivalent or comparable product at no charge. Since we have no control over surface preparation or application, THIS LIMITED LIFETIME WARRANTY DOES NOT INCLUDE THE COST OF LABOR FOR APPLICATION OF PAINT. BENJAMIN MOORE SHALL IN NO EVENT BE LIABLE FOR INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES DO NOT ALLOW THE EXCLUSION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE LIMITATIONS OR EXCLUSIONS CONTAINED IN THE ABOVE WARRANTY MAY NOT APPLY TO YOU. This warranty gives you specific legal rights; you may also have other rights which vary state to state. Limitations Do not apply when air or surface temperatures are below 35 °F (1.7 °C). For Wind‐Driven Rain over smooth and stable masonry only (non‐elastomeric use). Follow primer instructions. Technical Assistance Available through your local authorized independent Benjamin Moore retailer. call 1‐866‐708‐9180 visit www.benjaminmoore.com General Description A super premium quality, 100% acrylic exterior low lustre finish. AURA® Exterior combines the advantages of our proprietary Color Lock® Technology, Gennex® Color Technology, and latest resin technology to provide the ultimate exterior coating. Suitable for a variety of exterior substrates to provide a durable long‐lasting finish with rich colors that resist fading and stand up to rain, snow, wind, and UV damage. Excellent fade resistance and gloss retention Proprietary Color Lock® Technology for unparalleled color depth Breathable coating less prone to blistering, providing long‐term durability Low temperature application down to 35 °F Limited Lifetime Warranty Engineered with Gennex® Color Technology Dirt pick‐up resistant Usage Exterior surfaces such as wood, fiber cement board, hard board, vinyl and aluminum siding, shakes, unglazed brick, concrete, stucco, cinder block and primed metal. Colors Bases Colorant System White (01) Gennex® Bases 1X – 4X Gennex® Proprietary 100% Acrylic Titanium Dioxide 45.5 ± 2% 250 – 350 Sq. Ft. 4.6 – 6.4 mils 2.1 – 2.9 mils Technical Data / Base 1 Vehicle Pigment Volume Solids Spread Rate Per Gallon Wet: Recommended Film Thickness Dry: High Build System Coverage: 160 – 265 Sq. Ft. / 6 – 10 mils wet film thickness. Depending on surface texture and porosity. Be sure to estimate the right amount of paint for the job. This will ensure color uniformity and minimize the disposal of excess paint. 1 hour Dry Time @ 77 °F 4 hours (25 °C) @ 50% RH Painted surfaces can be washed after two weeks. High humidity and cool temperatures will result in longer dry, recoat and service times. Surface Temperature During Application Viscosity Flash Point Sheen / Gloss Clean Up Thinner Weight Per Gallon To Touch: To Recoat: Min: Max: 35 °F 100 °F 100 ± 4 KU None 9 – 15 @ 60° Water refer to page 2 12.5 lbs. 40 °F 90 °F .39 lbs./gal Storage Temperature Min: Max: 46.8 g/L VOC Benjamin Moore & Co., 101 Paragon Drive, Montvale, NJ 07645 Tel: (201) 573‐9600 www.benjaminmoore.com N634 US 091522 SPEC SHEET UV Sealant Water based acrylic 8.60-8.69 lbs. 1.03-1.04 kg 34.06-36.02% 32.36-33.86% <50 g/l Matte: 10-20 Satin: 25-35 Semi-Gloss:50-60 Gloss: >80 1 mil 3 mils 30 minutes 1 hour 1-2 hours 2-3 days 5 years 200°F TECHNICAL DATA MDM-26 MODERN MASTERS® MASTERCLEAR® SUPREME CLEAR COAT MASTERCLEAR SUPREME CLEAR COAT PHYSICAL PROPERTIES Resin Type Weight Solids Per Gallon Per Liter By Weight By Volume Volatile Organic Compounds Sheen Ranges @ 60° Recommended Dry Film Thickness (DFT) per Coat Wet Film to Achieve DFT (Unthinned material) Touch Handle Recoat Full Cure Dry Times at 77°F (25ºC) and 50% Relative Humidity Shelf Life Dry Heat Resistance Safety Information Practical Coverage at Recommended DFT (assume 15% material loss) 440-455 sq. ft./gal. For additional information, see SDS Calculated values are shown and may vary from the actual manufactured material. The technical data and suggestions for use contained herein are correct to the best of our knowledge, and offered in good faith. The statements of this literature do not constitute a warranty, express, or implied, as to the performance of these products. As conditions and use of our materials are beyond our control, we can guarantee these products only to conform to our standards of quality, and our liability, if any, will be limited to replacement of defective materials. All technical information is subject to change without notice. Rust-Oleum Corporation 11 Hawthorn Parkway Vernon Hills, Illinois 60061 Phone: 800∙942∙3166 www.modernmasters.com Form: ARJ-2352 Rev.: 110822 (7) A written maintenance plan that includes, but is not limited to, all technical information about the materials, the strength, durability, and maintenance requirements of the proposed Artwork, and any associated replacement costs. The two murals will receive two coats of an all surface primer and they will be painted with high quality exterior water based paint. Upon completion both murals will receive two coats of a high quality exterior UV protectant sealer with a semi gloss sheen. The surface will be fade resistant and can be cleaned with soap and water in the event that any dust or dirt collects on it. CITY OF AUSTIN ART IN PUBLIC PLACES PROGRAM/CULTURAL ARTS DIVISION USER DEPARTMENT PUBLIC ART EVALUATION FORM FOR TECHNICAL FEASIBILITY AND MAINTENANCE As per Section IX.A of the AIPP Guidelines, the user and managing departments responsible for housing the artwork are requested to review the artist’s final design (attached) for technical feasibility and maintenance considerations. Please provide a response on this form, or on letterhead signed by a representative in your department. Thank you! Department Artwork Title/Description Evaluation Date Evaluator’s Name Title EVALUATOR’S COMMENTS SITE INSTALLATION SAFETY / LIABILITY MAINTENANCE OTHER COMMENTS DEPARTMENTAL RECOMMENDATION (Attach additional sheets as necessary) Support artwork as proposed Signature: Support artwork with the following modification(s): User Department Director or designee Date: Murals for ATCEMS Station 5 and ATCEMS/AFD Station 7/8ATCEMS10-04-2024Eric JakubauskasDivision ChiefNo issues with the sites that have been identified for both murals by Mr. Angulo. No issues regarding safety for the two installation. No issues with the maintenance. Appreciate the artist using two coats of UVprotectant on the murals.No concerns with the installation. EMS is very excited to see Mr. Angulo's artwork come to fruition. We thank him for being flexible during the design process. Eric Jakubauskas, Division Chief ATCEMS10-04-2024 Artist Maintenance Questionnaire CITY OF AUSTIN-- AIPP Information captured in this questionnaire will be filed to help ensure the proper care and preservation of the artwork. You may reference the Conservation Review Form as you complete this questionnaire. Please be as specific as possible. (Attach additional sheets as needed) (This section to be completed by AIPP staff) Acc. #: Artist: Luis Angulo Title: Date created: est. December 2024 Medium: Acrylic and aerosol paints Dimensions: Date of Acq: General Information: General description of artwork: Do you have similar work (materials and techniques) in other collections? If so please provide the name/ owner of the collections. Materials and techniques: Please list ALL final materials used in the creation of the piece: Please list (or attach) manufacturer info for all products used in the final work: If cast or commercially fabricated, please provide information about the factory or foundry: EXHIBIT C - Artist Maintenance Questionnaire Please describe the reasons for selecting the final materials used: Please describe the method of creating the piece (describe special tools, methods, order of application, etc.): Please describe any coatings used: Please provide samples of materials, or documentation of materials and techniques employed: Samples attached (Circle one) YES NO Please describe any special needs (electricity, water, etc) or instructions for the installation of this piece: Please describe any media components used in this piece. Please complete attached Media Checklist. Preservation: Please share any opinions or recommendations regarding preventative preservation treatments. Please describe the extent to which changes in the appearance of the piece (as a result of aging and wear- and-tear) are intended/ accepted. How would you define damage? Please share your opinions on interventions; the condition at which an intervention should be considered; the extent to which the intervention is intended/ accepted: EXHIBIT C - Artist Maintenance Questionnaire Please list the frequency of cleaning or care needed, with specific techniques and/or products to be used. Please be detailed in the brand name or manufacturers’ specifications of products you would recommend, as well as step-by-step instructions for care. Signature Date EXHIBIT C - Artist Maintenance Questionnaire Projected Budget for EMS 5 & AFD 8 / EMS 7 (11) An updated Schedule. I will need two weeks per mural in order to complete the artwork. So a total of 4 weeks for completion. Scheduling the painting of the mural a contingent on when the walls are ready for me to paint on.