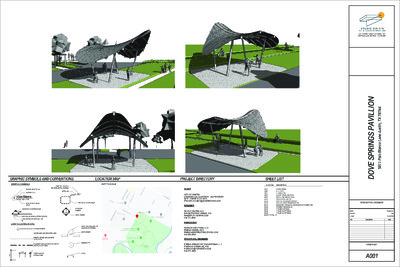

Item 09 - AIPP_Dove Springs_APH facility_Paloma_Pavillion Final Design.pdf — original pdf

Backup